COT-control-based ripple-compensation-based buck circuit power management chip

A power management chip and ripple compensation technology, applied in control/regulation systems, emergency protection circuit devices, electrical components, etc., can solve problems such as increased system loss, low safety, large capacitance and resistance, and improve noise resistance ability, improve work stability, and reduce the effect of system switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

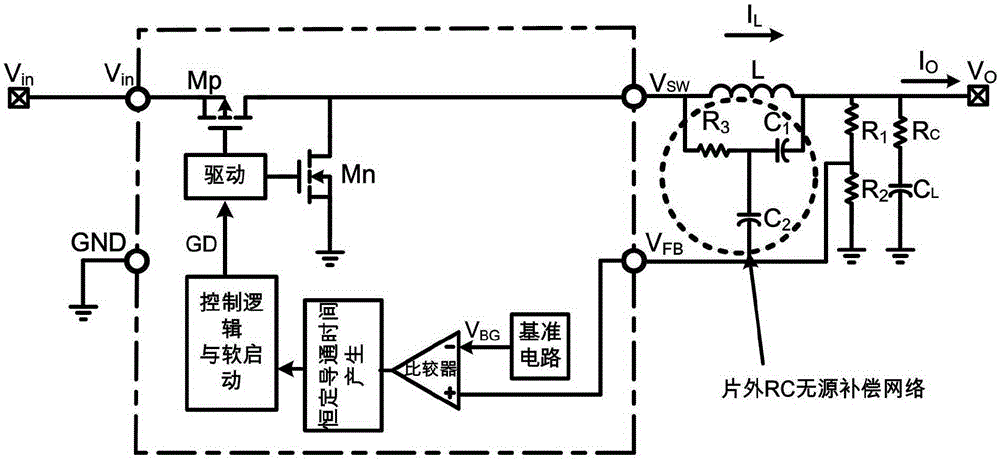

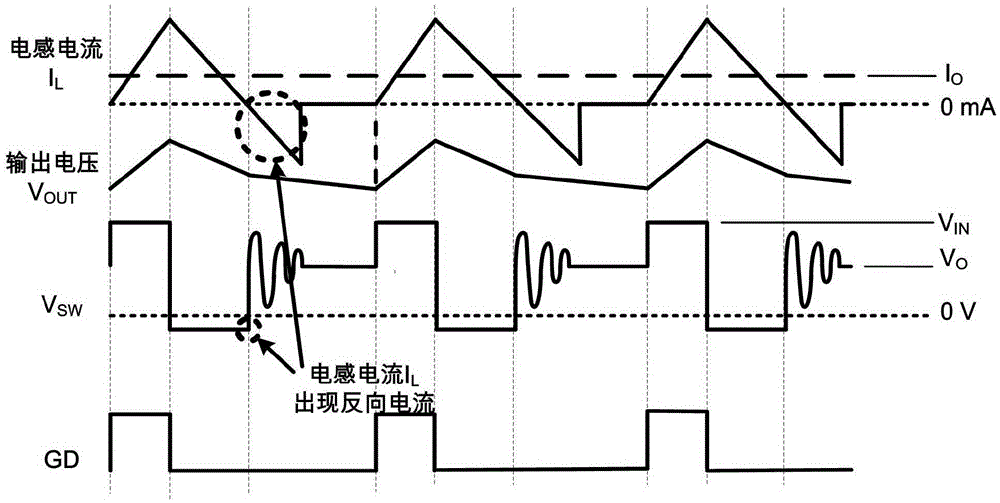

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

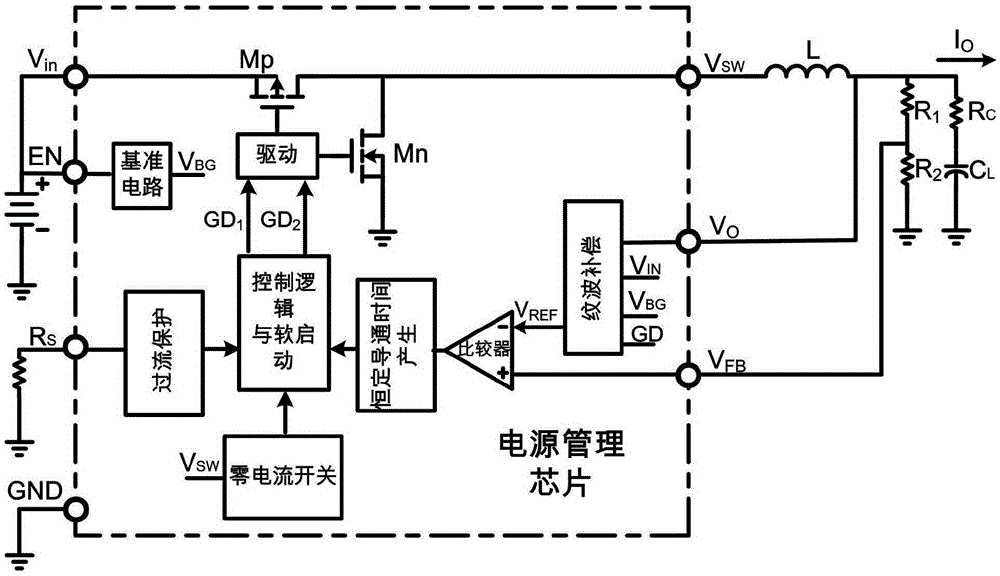

[0034] In order to describe the present invention in more detail, the technical solution of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0035] Such as image 3 As shown, the power management chip of the present invention is used in a large current buck circuit, and it is provided with a power input pin (V IN ), output voltage pin (V O ), ground pin (GND), enable pin (EN), overcurrent detection pin (R S ), feedback pin (V FB ) And switch SW pin (V SW ). The chip has a reference circuit module, an overcurrent protection module, a zero current switch module, a control logic and soft start module, a constant on-time generation module, a comparator module, a ripple compensation module, a drive module and two on-chip switching tubes Mp And Mn.

[0036] Power input pin (V IN ), access to each module in the chip to generate a power supply potential for each module in the chip to work normally. The grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com