A strip cooling process method and device between stands of an acid rolling mill

A cooling process and technology between racks, applied in the direction of workpiece cooling devices, rolls, metal rolling, etc., can solve the problems of unfavorable enterprises to reduce costs, increase production costs, and increase energy and medium consumption, so as to improve product quality and reduce total cost. The effect of flow rate and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

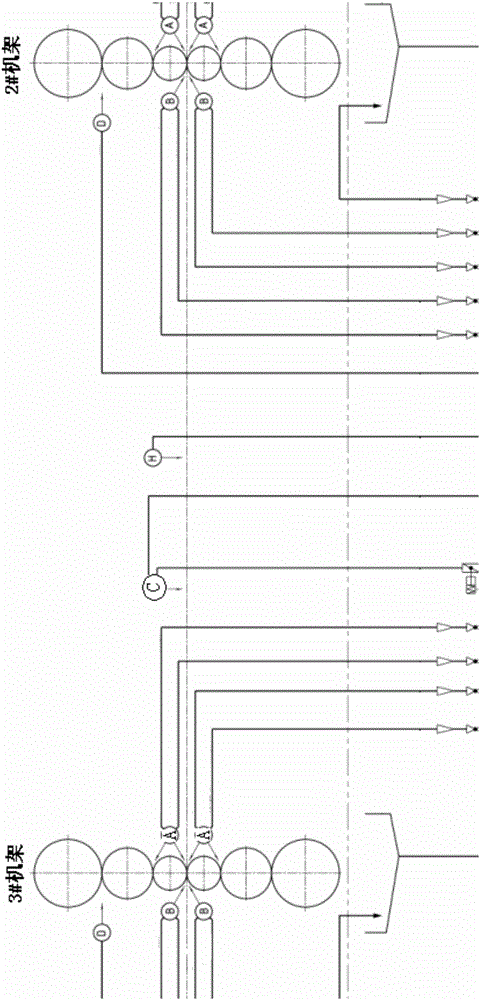

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

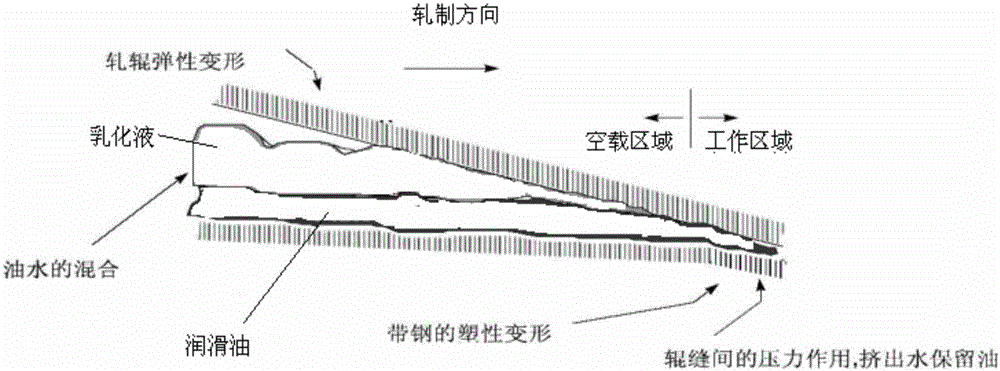

[0019] The emulsion system mainly plays four roles in the pickling mill: one is to lubricate during the rolling process, reduce the rolling power and prolong the life of the roll; the other is to take away the The dust produced on the surface of the steel and roll ensures good surface cleanliness of the strip after rolling; the third is that it can improve the thermal crown of the roll during the rolling process, so that the rolled strip can obtain good shape accuracy; Most of the heat generated by the frictional heat and the plastic deformation of the rolled material can be taken away in the heat balance of the heat balance, which is also the key optimization item of the present invention.

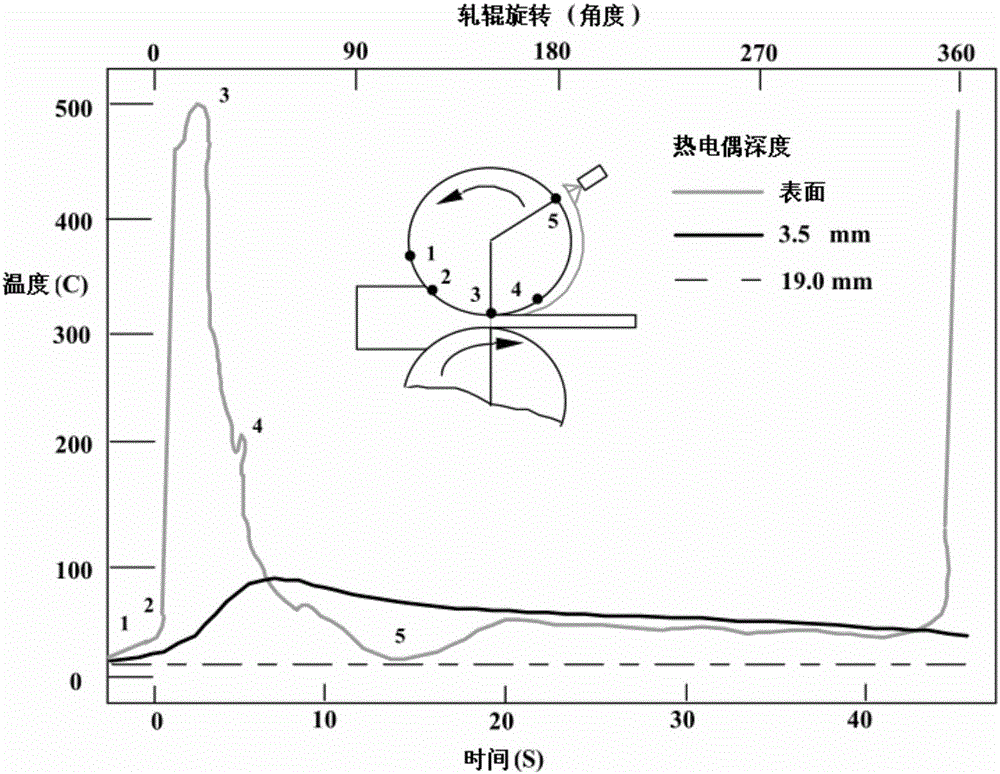

[0020] The deformation heat generated during rolling will increase the temperature of the strip steel and the roll. Since the heat generated by the friction between the strip a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com