Extrusion die as well as extrusion method and application thereof

A technology of extrusion dies and extrusion devices, which is applied in the direction of metal extrusion dies, metal extrusion, metal extrusion control equipment, etc., can solve the problems of small size and difficult realization, achieve quality improvement, reduce energy consumption, The effect of good organization and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Magnesium alloy AZ31b is carried out extruding, the method for extruding, comprises the following steps:

[0035] 1. Preheat the extruded billet, the preheating temperature is 400°C; fill the extrusion cylinder with billet and extrusion pad;

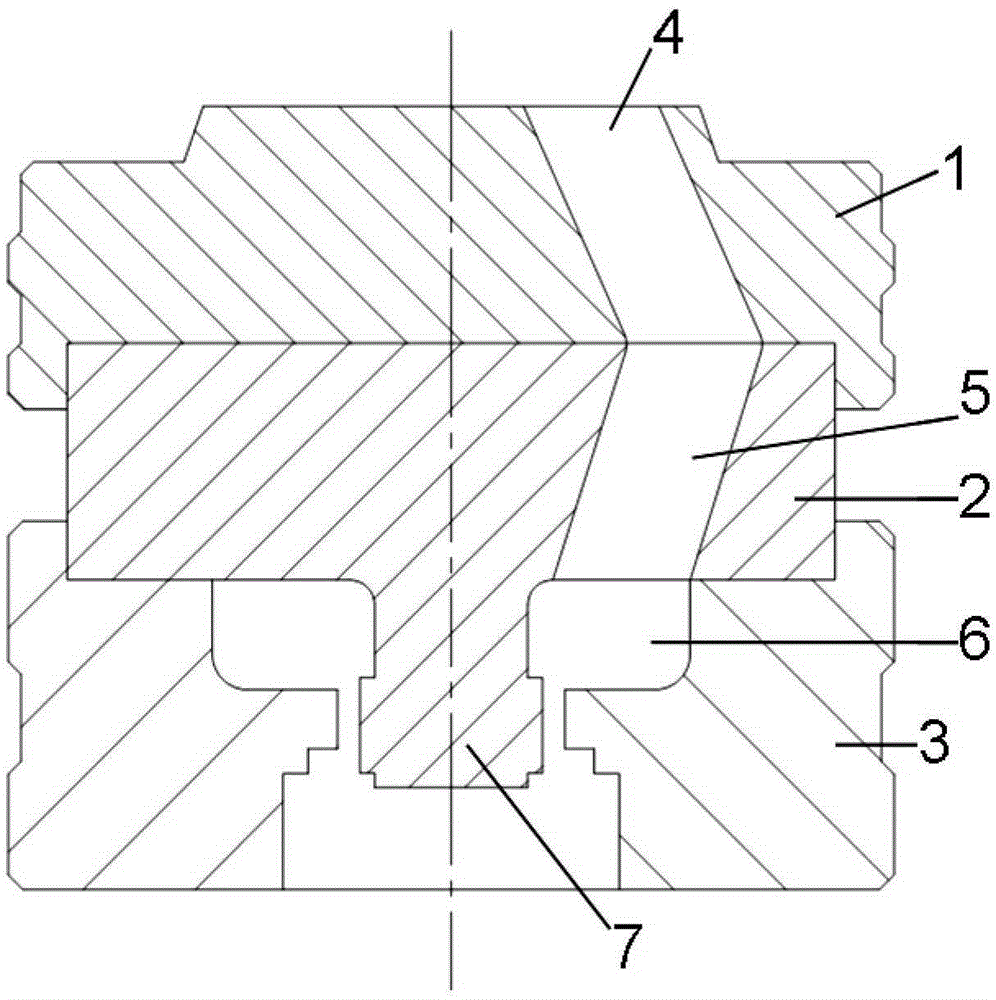

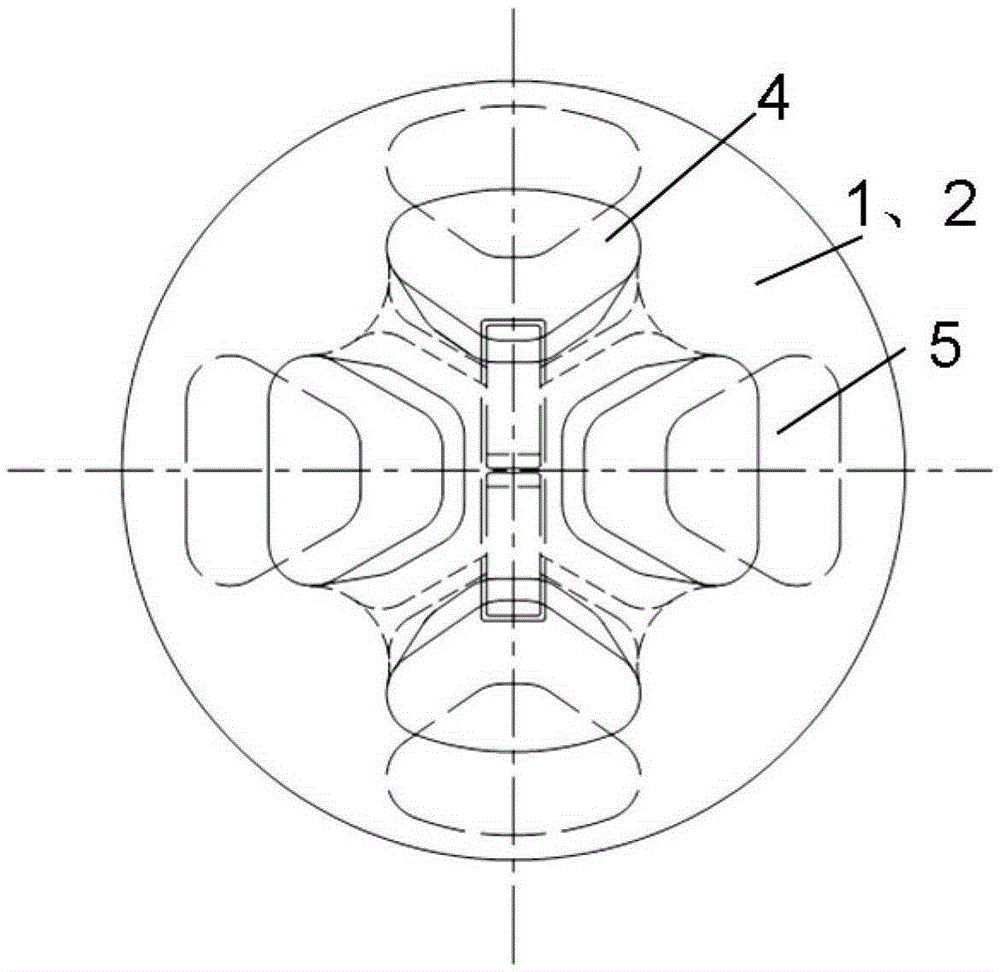

[0036] 2. Run the extruder, squeeze the billet into the split hole of the upper die through the extrusion rod, the angle between the upper section 4 and the lower section 5 of the split hole is 120°, and the extrusion speed is 0.4mm / s. The pressure is 8000kN, the blank undergoes plastic shear deformation in the split hole, and the grains are refined and uniform;

[0037] 3. The blank is welded in the welding room, and the welding temperature is 430°C;

[0038] 4. The final blank is extruded through the lower die to form a profile. The obtained profile has a width of 55mm and a wall thickness of 1.1mm, such as image 3 and Figure 4 As shown, it can be seen that the structure is uniform, the profile size is regular, the welding ...

Embodiment 2

[0040] Aluminum alloy AA6082 is extruded, and the method for extruding comprises the following steps:

[0041] 1. Preheat the extruded billet, the preheating temperature is 380°C; fill the extrusion cylinder with billet and extrusion pad;

[0042] 2. Run the extruder, squeeze the billet into the split hole of the upper die through the extrusion rod, the angle between the upper section 4 and the lower section 5 of the split hole is 135°, and the extrusion speed is 0.4mm / s. The pressure is 7000kN, the blank undergoes plastic shear deformation in the split hole, and the grains are refined and uniform;

[0043] 3. The blank is welded in the welding room, and the welding temperature is 410°C;

[0044] 4. The final billet is extruded through the lower die to form a profile. The obtained profile has a diameter of 55 mm and a wall thickness of 1.1 mm. like Figure 5 As shown, it can be seen that the structure is fine and uniform, the profile size is regular, and the welding is good...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com