Processing technology of large-volume thick-walled high-pressure hydrogen storage steel liner

A processing technology and large-volume technology, applied in the field of large-capacity high-pressure gas storage equipment, can solve the problems of large shock and vibration, difficult spinning, large thread shear stress, etc., and achieve fast solidification, fast cooling, and greatly increased deformation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

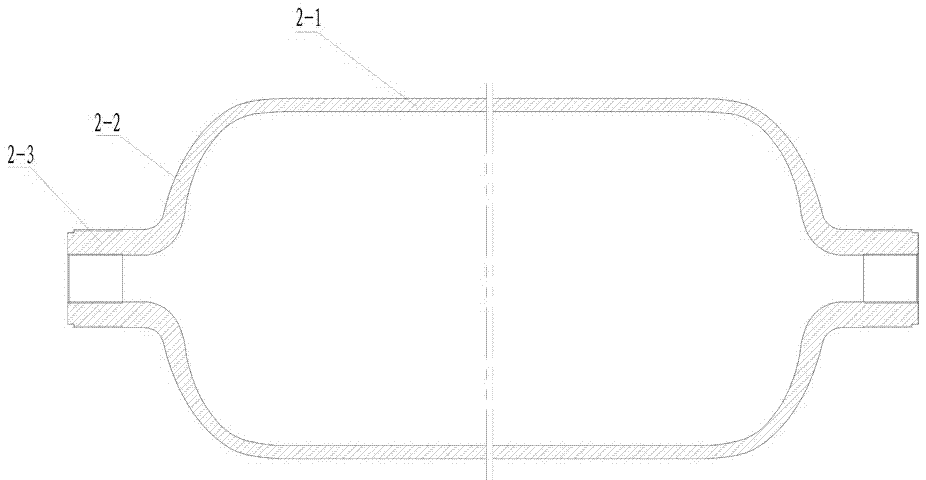

[0023] In this embodiment, taking the spinning of a seamless steel pipe blank with a diameter of 600 mm and a length of 3200 mm as an example, the processing technology of the steel liner is introduced in detail. Include the following steps:

[0024] Step 1. Heating the closing section of the seamless steel pipe billet to 1000-1180° C.; the length of the closing section is about 400-700 mm.

[0025] In order to reduce the metal deformation resistance, reduce the spinning impact force, and effectively protect the equipment, it is necessary to supplement the heat in the heated deformation area during the entire spinning process, reduce the cooling speed of the spinning deformation area, and make regulations on the final spinning temperature, generally not Below 900°C.

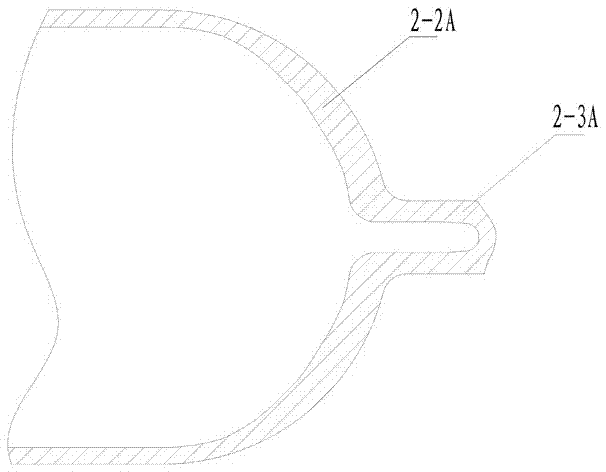

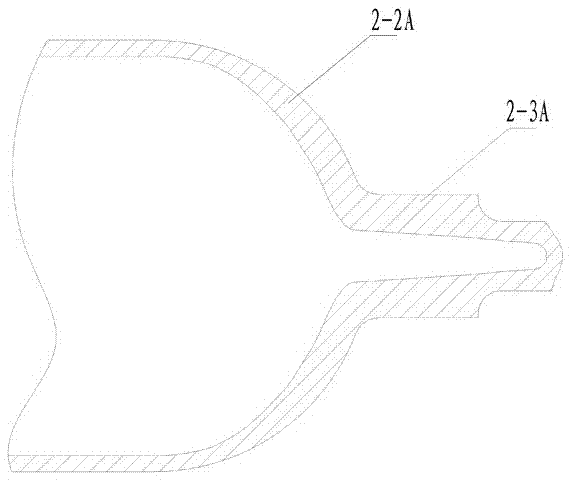

[0026] Step 2. Spinning head 2-2A and aggregate head 2-3A: Supplement heat to the closing section, clamp the outer wall of the seamless steel pipe blank with the jaws of the main shaft of the spinning machine, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com