Antibacterial anti-mildew algae-preventing yacht cloth and manufacture method thereof

An antibacterial, mildew-proof and production method technology, applied in the field of fabrics, can solve the problems of imperfect production equipment and achieve the effect of increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

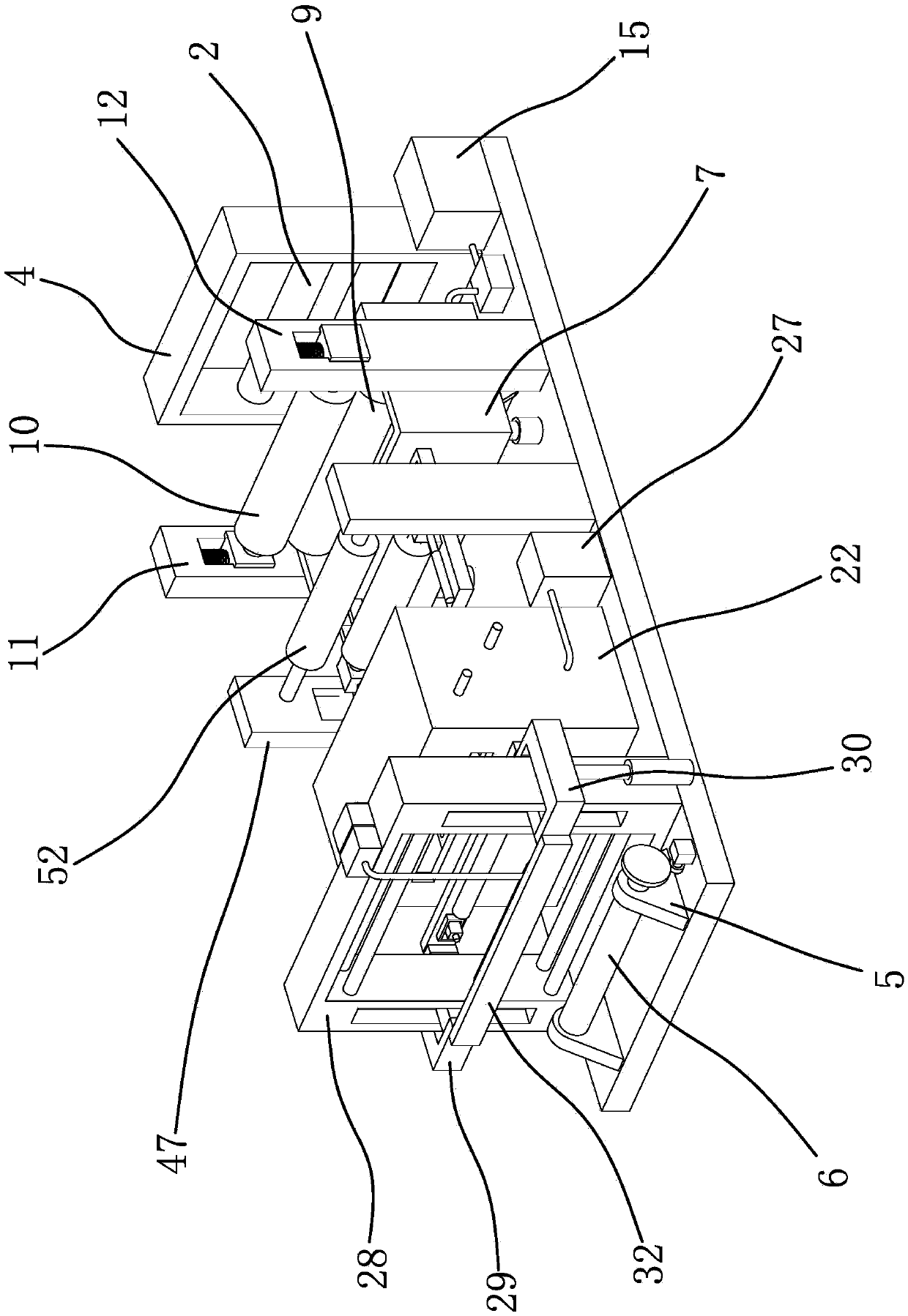

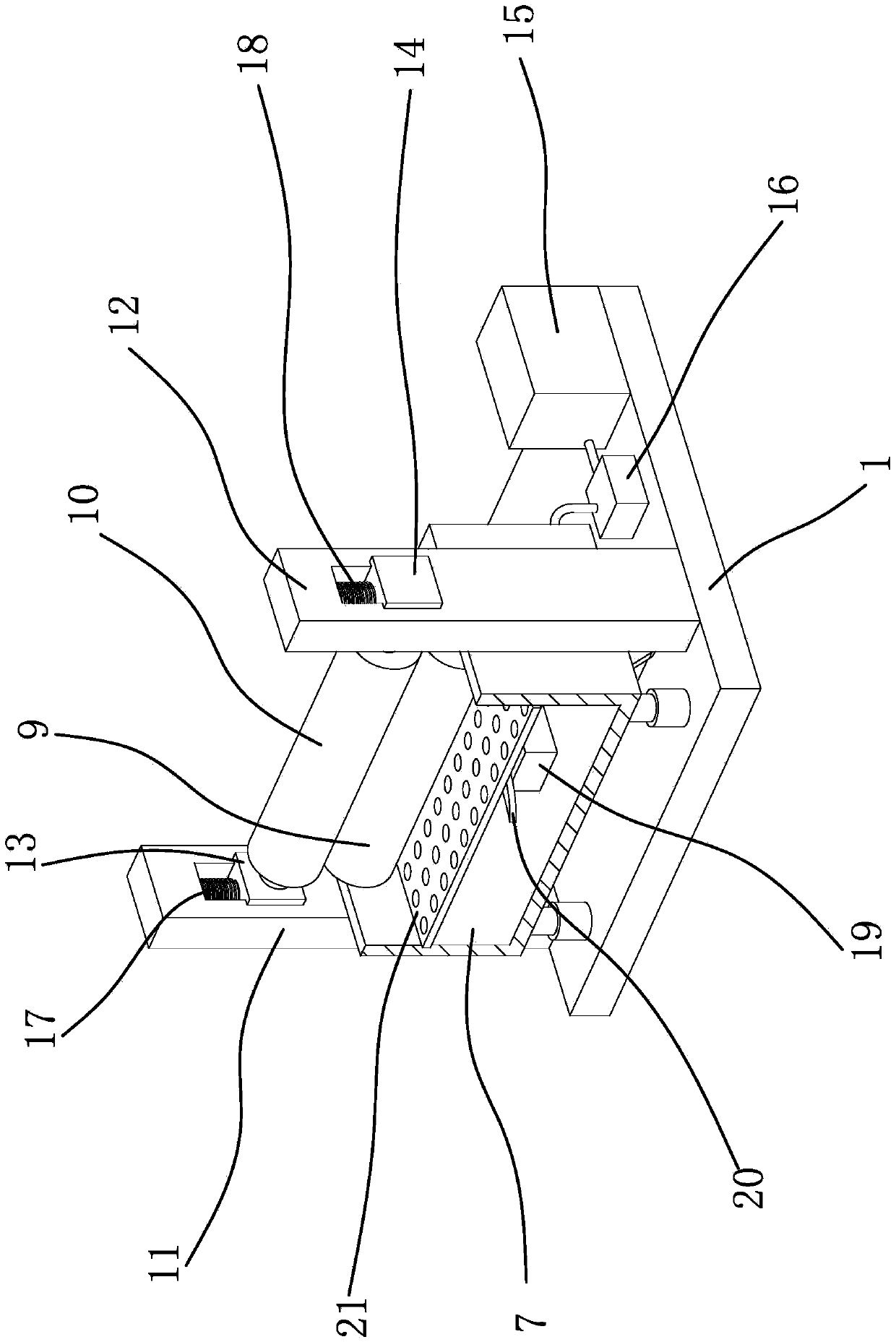

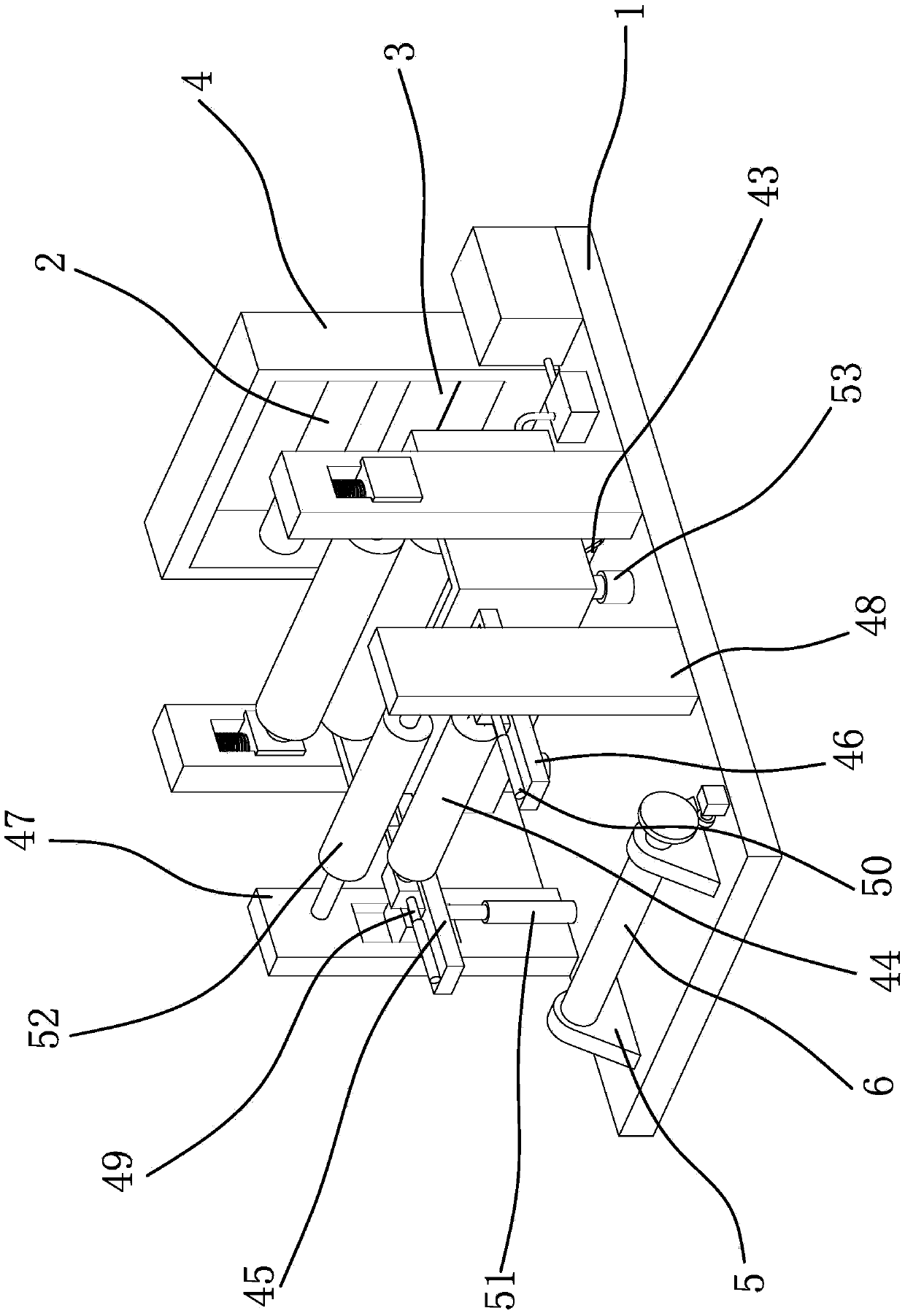

[0041] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0042] The antibacterial, anti-mildew and anti-algae yacht cloth includes a base cloth layer, which is characterized in that a PVC film is attached to the front surface of the base cloth layer and the reverse side of the base cloth layer, and there is an adhesive layer between the PVC film and the base cloth layer. The PVC film includes the following components in parts by weight: 95-105 parts of PVC resin powder, 45-55 parts of plasticizer DINP, 3-5 parts of epoxy soybean oil, 10-12 parts of nanometer calcium powder, 0.5 parts of anti-mold agent -3 parts, 1-2.5 parts of rutile titanium dioxide, 0.1-0.5 parts of anti-UV agent, 9-11 parts of chlorinated paraffin. The antibacterial, anti-mildew and anti-algae yacht cloth includes a ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com