Cement grinding aid, preparation method therefor and application thereof

A cement grinding aid and cement technology, which is applied in the field of chemical building materials, can solve the problems of cement grinding aid formula composition change, chemical complexation addition reaction, and reducing enterprise benefits, etc., to achieve high fluidity and good surface dispersion , good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

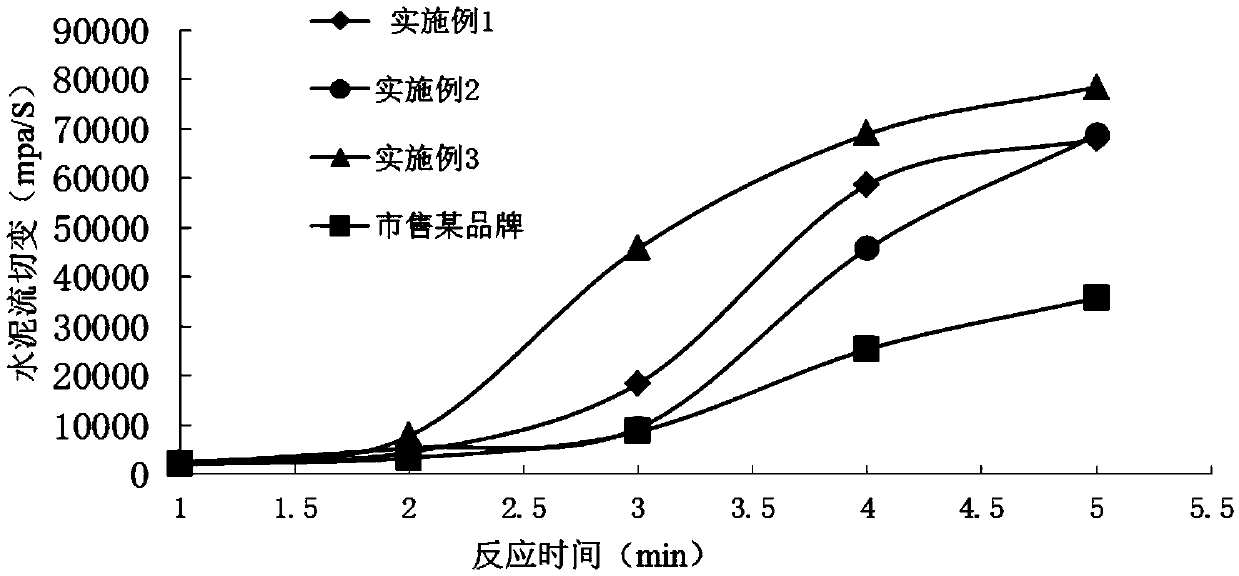

Embodiment 1

[0025] Prepare cement grinding aid of the present invention according to the following steps:

[0026] Step 1. Treat 330 parts of ultrapure water with a conductivity of 0.01Mv for 5 minutes through a particle accelerator and then inject it into an anion exchange column for adsorption for 10 minutes. The anion exchange column is eluted with strong acid and weak base salt, and the eluent Add it into the reaction kettle, start the stirring motor of the reaction kettle, the speed of the mixer is 80 rpm, add 2 parts of trinitrom-phenylenediamine, 3 parts of benzylethylaniline, and 2 parts of terpene phenol resin in turn, and start the reaction kettle High-pressure steam switch, high-temperature and high-pressure steam is passed into the heat exchanger, so that the temperature in the reactor rises to 60°C, and the temperature is kept for 1 hour;

[0027] Step 2, take 9 parts of fly ash, 6 parts of titanium dioxide and 2 parts of silicon dioxide, mix and grind to a particle size of 4...

Embodiment 2

[0031] Prepare cement grinding aid of the present invention according to the following steps:

[0032] Step 1. Treat 990 parts of ultrapure water with a conductivity of 0.05Mv for 10 minutes through a particle accelerator and inject it into an anion exchange column for adsorption for 20 minutes. The anion exchange column is eluted with strong acid and weak base salt, and the eluent Add it into the reaction kettle, start the stirring motor of the reaction kettle, the speed of the mixer is 120 rpm, add 7 parts of trinitrom-phenylenediamine, 7 parts of benzylethylaniline, and 4 parts of terpene phenol resin in sequence, and start the reaction kettle High-pressure steam switch, high-temperature and high-pressure steam is passed into the heat exchanger, so that the temperature in the reactor rises to 80 ° C, and the temperature is kept for 2 hours;

[0033] Step 2, take 21 parts of fly ash, 8 parts of titanium dioxide and 5 parts of silicon dioxide, mix and grind to a particle size...

Embodiment 3

[0037] Prepare cement grinding aid of the present invention according to the following steps:

[0038] Step 1, 730 parts of ultrapure water with a conductivity of 0.035Mv was treated by a particle accelerator for 8 minutes and then injected into an anion exchange column for adsorption for 15 minutes. The anion exchange column was eluted with strong acid and weak base salt, and the eluent Add it into the reaction kettle, start the stirring motor of the reaction kettle, the speed of the mixer is 90 rpm, add 5 parts of trinitrom-phenylenediamine, 5 parts of benzylethylaniline, and 3 parts of terpene phenol resin in sequence, and start the reaction kettle High-pressure steam switch, high-temperature and high-pressure steam is passed into the heat exchanger, so that the temperature in the reactor rises to 70 ° C, and the temperature is kept for 1.5 hours;

[0039] Step 2, take 10 parts of fly ash, 7 parts of titanium dioxide and 4 parts of silicon dioxide, mix and grind to a partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com