Method for plating aluminum oxide device with vacuum ion titanium nitride

A technology of vacuum ion plating and aluminum oxide billets, which is applied in the field of aluminum oxide devices to achieve the effects of reducing product costs, high hardness, and saving pure gold materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

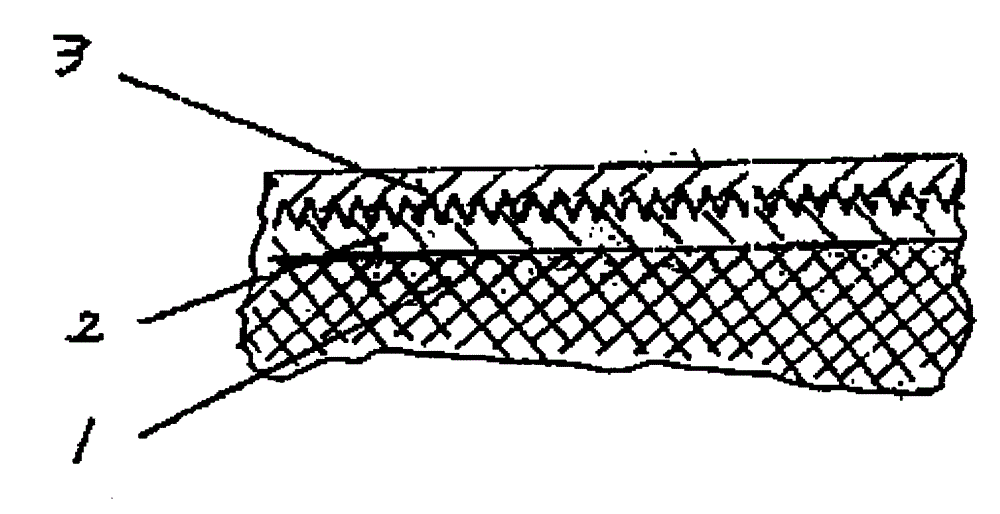

[0017] see figure 1 As shown, the present invention comprises aluminum oxide green body 1, and this aluminum oxide green body 1 is the daily-use utensil that is made of pottery clay or porcelain clay, such as building tiles, house tiles, bowls, plates, spoons of tableware , saucers, spoons, pots, bottles, oatmeal, bowls, cans, jars, pots and cups of tea sets, or various figures and animals made of clay and porcelain clay. 1 Put it into the vacuum ion coating machine, first coat a layer of vacuum ion plating zirconium layer 2 on its surface, and then apply vacuum ion plating titanium nitride layer 3 on the outside of the vacuum ion plating zirconium layer 2 by vacuum ion plating technology . Since the vacuum ion-plated zirconium layer 2 not only has a good bonding force with the aluminum oxide billet 1, but also has excellent compatibility with the vacuum ion-plated titanium nitride layer 3, it is in contact with the vacuum ion-plated titanium nitride layer 3 , the surface is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com