M-benzene type epoxy vinyl ester glass fiber reinforced plastic resin and synthetic method thereof

A technology of epoxy vinyl ester and glass fiber reinforced plastic resin, which is applied in the field of polymer compound synthesis, can solve problems such as unsatisfactory, limited tolerance, and decreased strength of resin materials, and achieve good acid and alkali corrosion resistance, excellent toughness, and no The effect of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A, 455g epoxy resin E44, 49.8g isophthalic acid, 4.17g benzyltriethylammonium bromide are dropped into in the four-necked flask with thermometer, stirrer, vertical condenser successively, start to stir;

[0025] B. Raise the temperature to 170°C until the reaction is clear, then keep it warm for 1 hour until the acid value is between 4-5mgKOH / g;

[0026] C. Cool down to 110°C, add 0.21g o-methyl hydroquinone and 0.15g tert-butyl p-methylphenol in turn, add 120.4g methacrylic acid dropwise using a dropping funnel, and control the rate of methacrylic acid addition at The dropwise addition is completed within 1 hour; after the drop is completed, it is kept at 110°C for 3 hours until the acid value is between 18-20mgKOH / g;

[0027] D. Cool down to 85°C, add 764.1g styrene to dilute, after dilution, keep warm at 60°C, stir for 45 minutes until uniform, filter to obtain yellow transparent viscous liquid, i.e. isophthalic epoxy vinyl ester FRP resin.

Embodiment 2

[0029] A. Put 117kg epoxy resin E51, 19.9kg isophthalic acid, and 0.34kg benzyldimethylamine into the reaction kettle in turn, and start stirring;

[0030] B. Raise the temperature to 175°C until the reaction is clear, keep it warm for 1 hour until the acid value is between 4-5mgKOH / g;

[0031] C. Cool down to 110°C, add 0.068kg hydroquinone and 0.068kg tert-butyl p-methylphenol successively, add 31.0kg methacrylic acid dropwise, and control the acceleration rate of methacrylic acid to add dropwise within 1 hour; at 110 Incubate at ℃ for 3 hours until the acid value is between 14-16mgKOH / g;

[0032] D. Cool down to 90°C, add 167.9kg styrene to dilute, after dilution, keep warm at 55°C, stir for 1 hour until uniform, filter to obtain yellow transparent viscous liquid, i.e. isophthalic epoxy vinyl ester FRP resin.

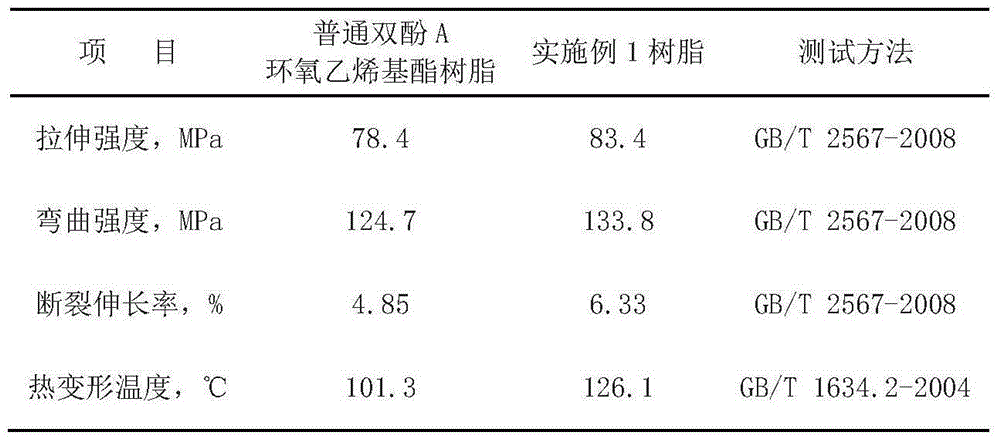

[0033] Embodiment 1 of the present invention compares with the performance index of common bisphenol A epoxy vinyl ester resin:

[0034]

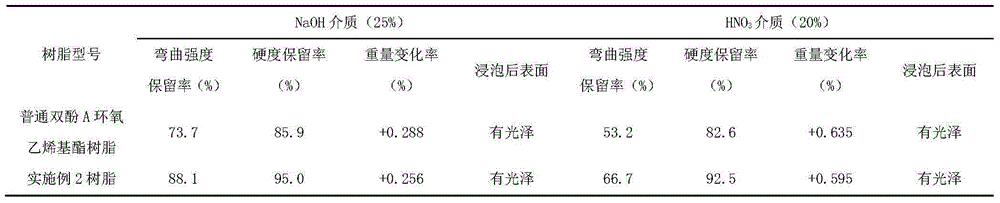

[0035] Embodiment 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com