Permeable epoxy seal primer and preparing method and using method thereof

A technology of sealing primer and permeability, applied in primers, epoxy resin coatings, coatings, etc., can solve the problems of easy foaming, poor permeability, poor sealing, etc., and achieve easy foaming and permeability. High, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 permeable epoxy sealing primer, its components and parts by weight are as follows:

[0019] Component name

parts by weight

100% epoxy solid resin

70 copies

Thinner

22 copies

adhesion promoting resin

0.5 parts

75% epoxy resin

40 copies

Adhesion Promoter

4 parts

penetration aid

1 copy

1 copy

Thinner

30 copies

[0020] The thinner in the raw material of the penetrating epoxy sealing primer is xylene.

[0021] The preparation method provided in this example is described as follows: Take 70 kg of 100% epoxy solid resin and add it to the reactor, raise the temperature to 200 ° C, keep the temperature for 40 minutes, stir and cool down to the temperature in the reactor less than or equal to 150 ° C, and start adding 22 kilograms of thinner, 0.5 kilograms of adhesion-promoting resin, and continue to stir for 30 minutes to obtain a preliminary mi...

Embodiment 2

[0023] Embodiment 2 permeable epoxy sealing primer, its components and parts by weight are as follows:

[0024] Component name

parts by weight

100% epoxy solid resin

75 copies

Thinner

24 copies

adhesion promoting resin

1 copy

75% epoxy resin

50 copies

Adhesion Promoter

6 servings

penetration aid

2 copies

plasticizer

2 copies

Thinner

40 copies

[0025] The thinner in the raw material of the penetrating epoxy sealing primer is xylene.

[0026] The preparation method provided in this example is described as follows: Take 75 kg of 100% epoxy solid resin and add it to the reactor, raise the temperature to 200 ° C, keep the temperature for 40 minutes, stir and cool down to the temperature in the reactor less than or equal to 150 ° C, and start adding 24 kilograms of thinner, 1 kilogram of adhesion promoting resin, and continue to stir for 30 minutes to obtain a preliminary mi...

Embodiment 3

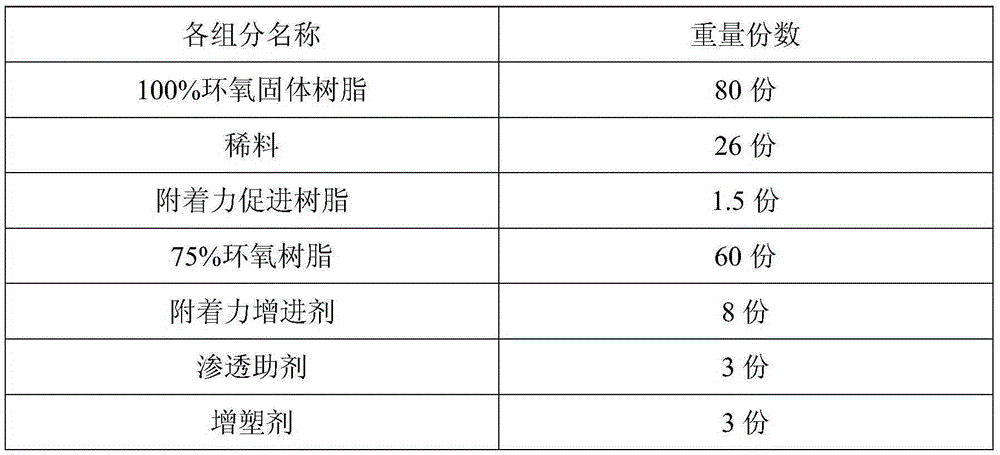

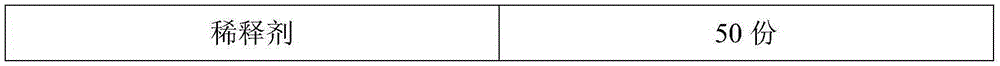

[0028] Embodiment 3 permeable epoxy sealing primer, its component and parts by weight are as follows:

[0029]

[0030]

[0031] The thinner in the raw material of the penetrating epoxy sealing primer is xylene.

[0032] The preparation method provided in this example is described as follows: Take 80 kg of 100% epoxy solid resin and add it to the reactor, raise the temperature to 200 ° C, keep the temperature for 40 minutes, stir and cool down to the temperature in the reactor less than or equal to 150 ° C, and start adding 26 kilograms of thinner, 1.5 kilograms of adhesion-promoting resin, and continue to stir for 30 minutes to obtain a preliminary mixture, put the above-mentioned preliminary mixture, 60 kilograms of 75% epoxy resin in the color tank, add 50 kilograms of diluent and mix, stir for 30 minutes Add 3 kilograms of penetration aids, 3 kilograms of plasticizers, and 8 kilograms of adhesion promoters one minute later, and continue stirring for 60 minutes to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com