Full-polyimide foam honeycomb and manufacturing method thereof

A technology of all-polyimide and polyimide honeycomb paper, which is applied in the direction of textiles and papermaking, can solve the problems of reduced service life of aramid paper honeycomb core, and achieve the advantages of increasing strength, maintaining rigidity, and outstanding compressive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

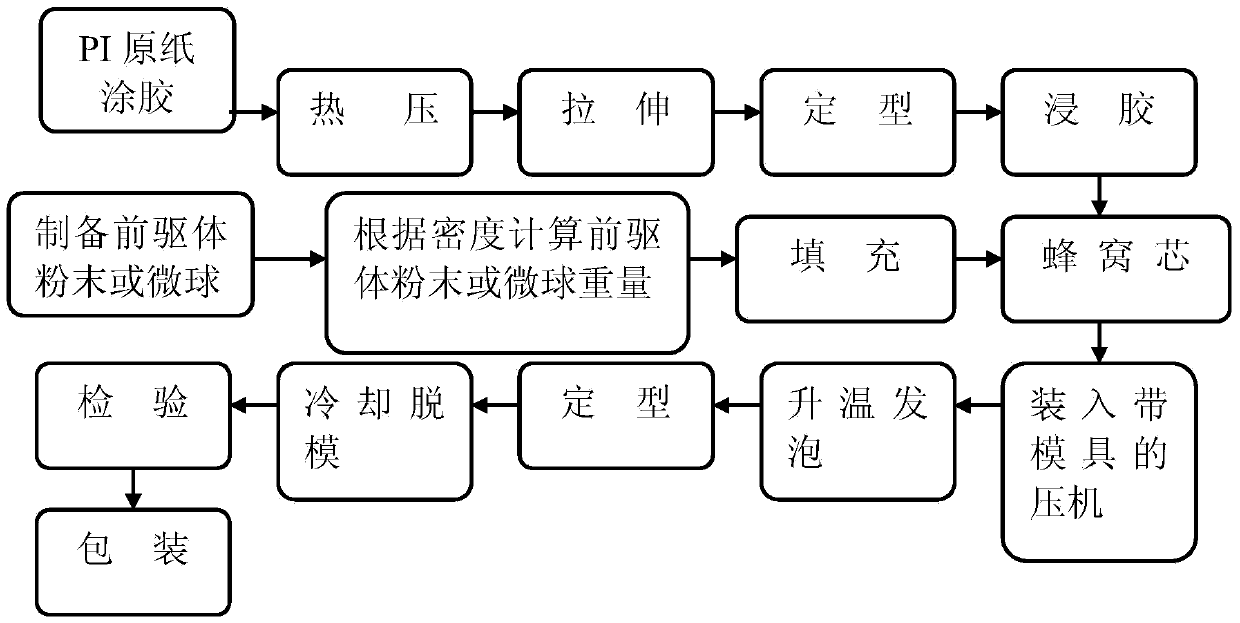

[0030] The present invention also provides a kind of preparation method of polyimide foam honeycomb, it is characterized in that, comprises the following steps:

[0031] A) after polyimide paper is processed, obtain polyimide paper honeycomb core;

[0032] B) adding the polyimide foam precursor into the honeycomb holes of the polyimide paper honeycomb core obtained in the above step A), and heating and foaming to obtain a polyimide foam honeycomb.

[0033] In the present invention, polyimide paper is first processed to obtain a polyimide paper honeycomb core; the present invention has no special restrictions on the processing, and the polyimide paper is molded with the process known to those skilled in the art. The process is enough. In order to improve the characteristics of the polyimide foam honeycomb, the present invention preferably includes the steps of gluing, hot pressing, stretching, dipping, shaping and slicing.

[0034] The steps of gluing, hot pressing and stretch...

Embodiment 1

[0043] First, the surface of the polyimide paper is coated with polyimide glue, and then multi-layers are stacked according to the shape of the honeycomb core, then preheated at 80°C for 50 minutes, and then gelled at 130°C for 100 minutes, and finally Cured at 240°C for 4 hours under the condition of hot pressing pressure of 6MPa. The above-mentioned hot-pressed polyimide paper was stretched by a stretching machine at a stretching speed of 12 mm / min, and then dried in an oven at 300° C. for 40 minutes to obtain a polyimide paper with a honeycomb structure.

[0044] Then, the polyimide paper with honeycomb structure obtained in the above steps is dipped in a dipping machine, and the dipping solution is composed of 10 wt% polyimide resin and dimethylacetamide. After dipping, preheat in an oven at 75°C for 30 minutes, then dry at 130°C for 100 minutes, gel at 210°C for 3 hours, and finally cure at 370°C for 4 hours, then cut into slices to obtain a side length of 6mm and a size ...

Embodiment 2

[0049] First, the surface of the polyimide paper is coated with polyimide glue, and then multi-layers are stacked according to the shape of the honeycomb core, then preheated at 75°C for 40 minutes, and then gelled at 135°C for 120 minutes, and finally Curing at 200°C for 3 hours under the condition of hot pressing pressure of 7MPa. The hot-pressed polyimide paper was stretched with a stretching machine at a stretching speed of 10 mm / min, and then dried in an oven at 320° C. for 30 minutes to obtain a polyimide paper with a honeycomb structure.

[0050] Then, the polyimide paper with honeycomb structure obtained in the above steps is dipped in a dipping machine, and the dipping solution is composed of 30 wt% polyimide resin and dimethylacetamide. After dipping, preheat in an oven at 90°C for 40 minutes, then dry at 140°C for 90 minutes, gel at 240°C for 2 hours, and finally cure at 370°C for 5 hours, then cut into slices to obtain a side length of 6mm and a size of 50*50*10mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com