a mixing pump

A mixed pump and the other side technology, applied in the field of fluid machinery, can solve the problems of difficult separation of sediment, large changes in oil-gas ratio, unstable downhole pressure in oil fields, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

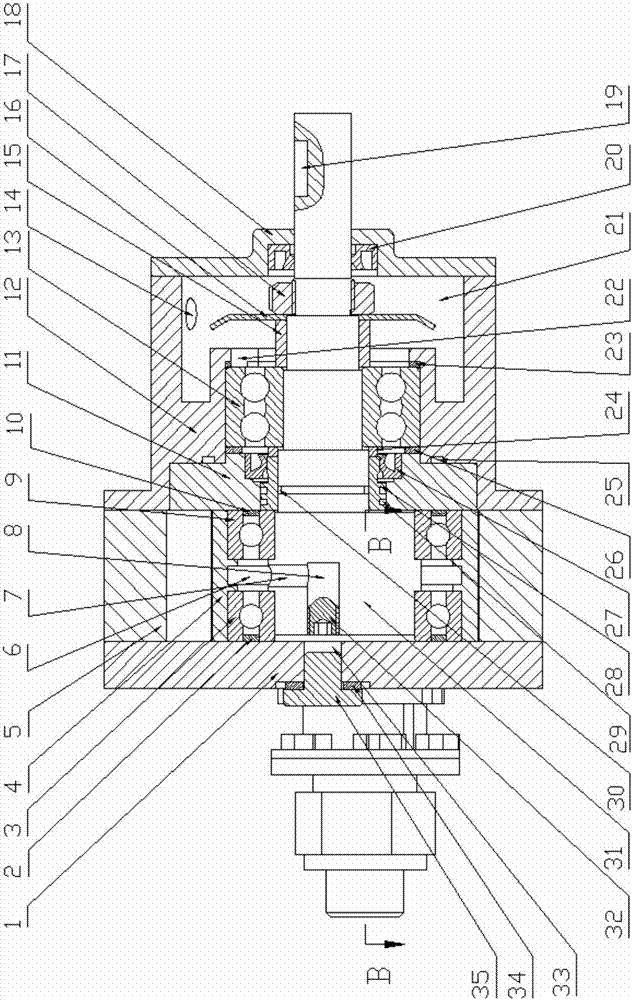

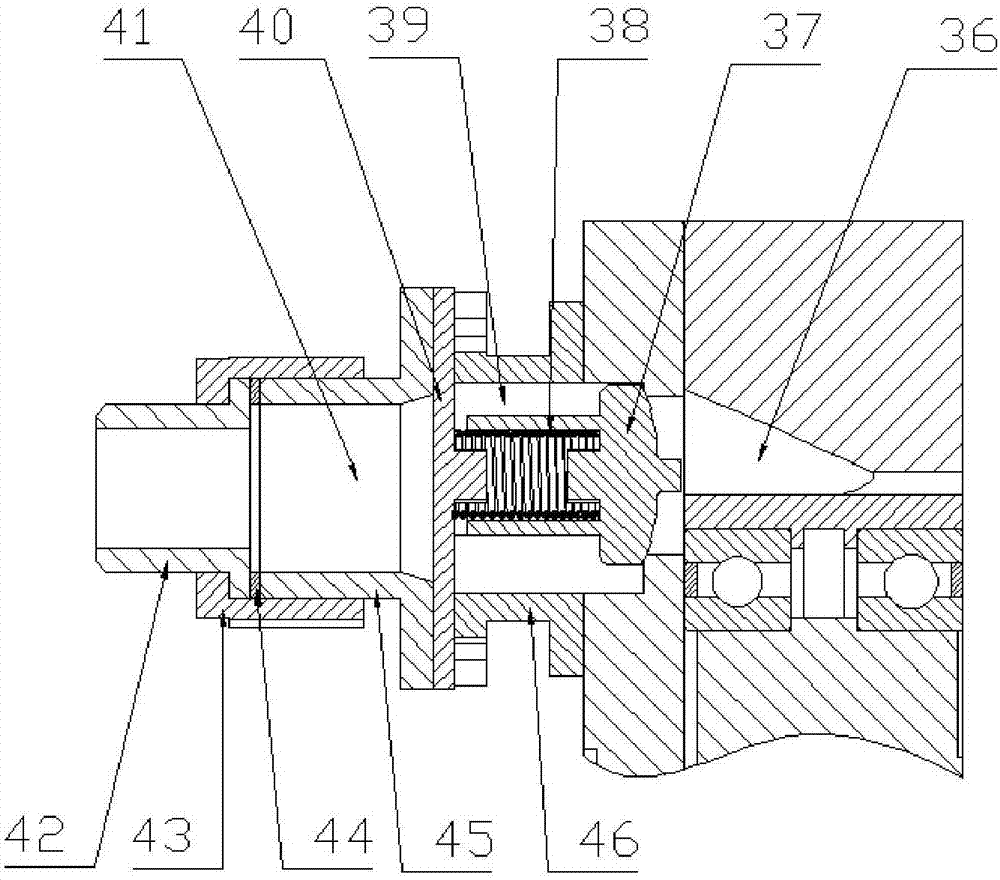

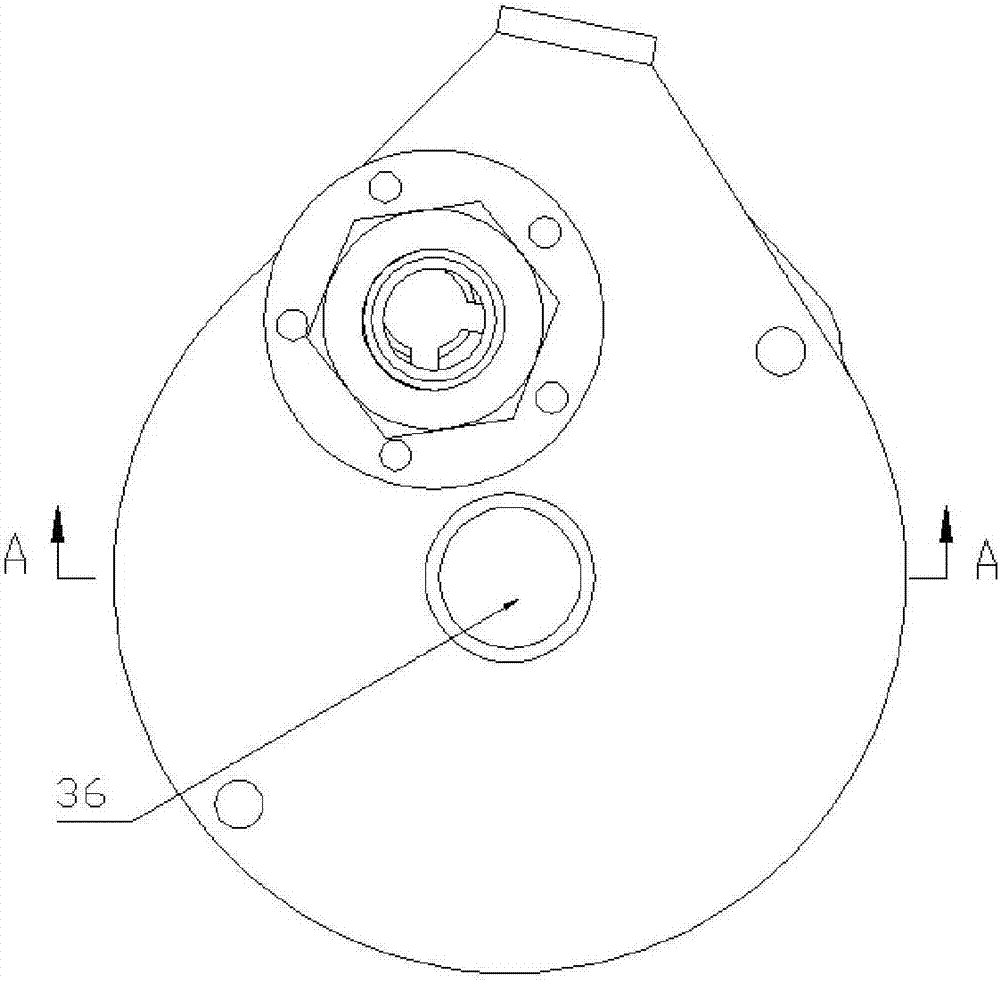

[0022] In order to better illustrate the intention of the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Please refer to Figure 1-3 , the mixed transport pump shown in the figure, which includes a cylinder body 5, a left end cover 1 is installed on one end of the cylinder body 5, the other side of the left end cover 1 communicates with the outlet pipeline, and an oil tank and a bearing seat are installed on the other end of the cylinder body 5 12. A rotor 4 and a crankshaft 31 are arranged in the inner cavity of the cylinder body 5, and the crankshaft 31 is arranged along the horizontal direction. The rotor 4 can swing with the crankshaft 31 in a plane, and the outer wall surface of the rotor 4 is always tangent to the inner wall surface of the cylinder body 5. , the direction of rotation is determined by the settings of the inlet and outlet. Between the rotor 4 and the crankshaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com