Pressure difference protection system of pitching cylinder for container front stacker

A technology for pitching cylinders and protection systems, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems of hydraulic system impact, waste of power absorbed by the pump, and endanger the safety of surrounding personnel and goods, etc., to achieve Stable output power, rapid output flow, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

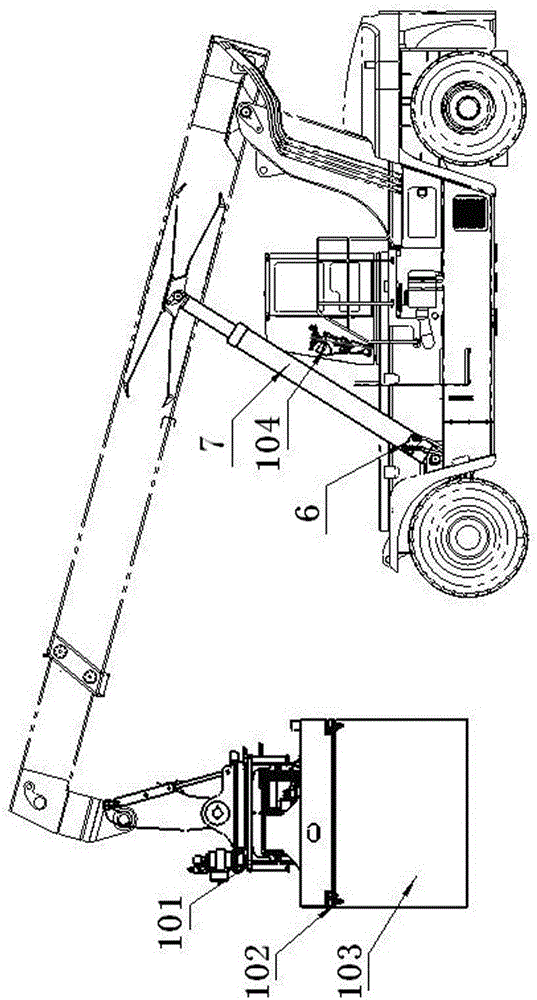

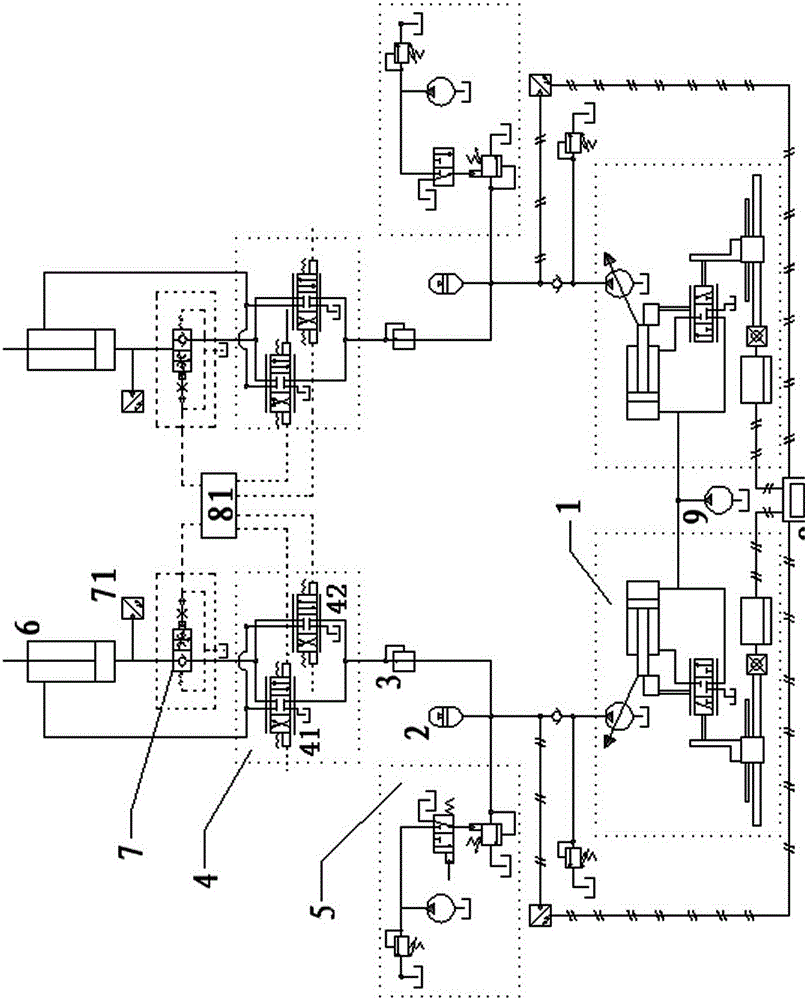

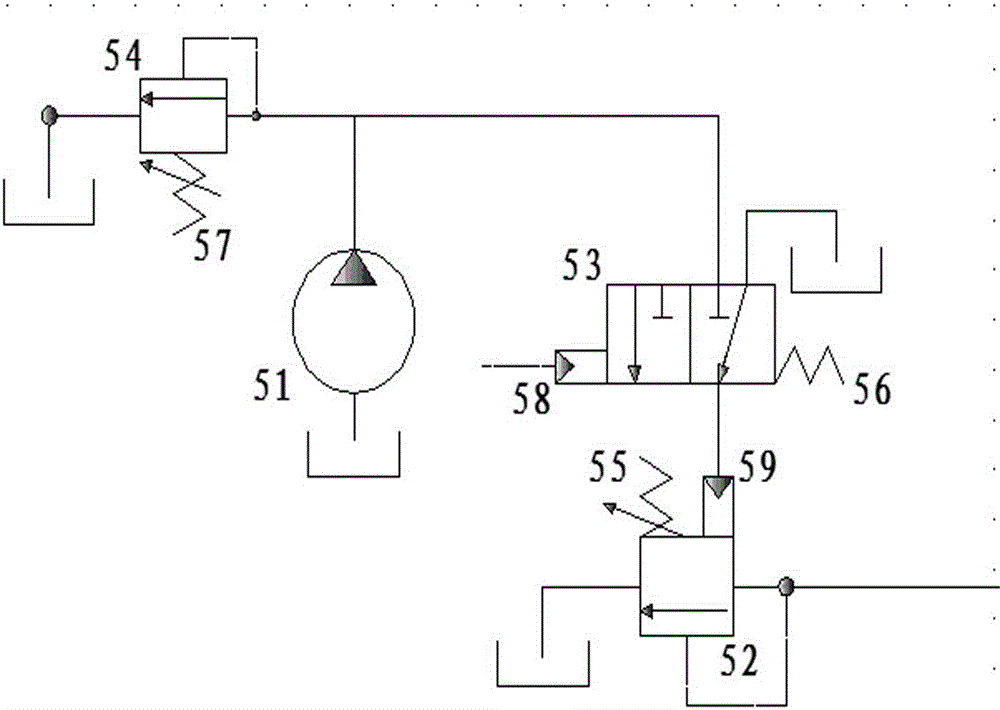

[0076] figure 1 It is a schematic diagram of the structure of the pressure difference protection system of the luffing cylinder used for container reach stackers of the present invention; since the hydraulic systems of the left and right luffing cylinders involved in the present invention are completely the same, only the hydraulic system of the left luffing cylinder 6 on the left side Introduced, the same as the one on the right. Among them, a balance valve 7 is installed on the load chamber oil ports of the left and right pitch cylinders 6, and a cylinder pressure sensor transmitter 71 (see figure 2 ) Monitor the pressure of the left pitching cylinder 6 in real time. When the container reach stacker lifts the container 103, the pressure on the two pitching cylinders will be displayed on the instrument 104. When the pressure difference between the two cylinders is greater than the set value, Gauge 104 will display a pressure alarm. It is not allowed to continue to operate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com