Parallel remote optical fiber sensing system for detecting various gas refractive indexes

An optical fiber sensing system, a technology of gas refractive index, applied in the sensing field, can solve the problems of slow measurement speed, high price, and strict integration processing requirements, and achieve the effects of reducing cost, increasing contact area, and increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

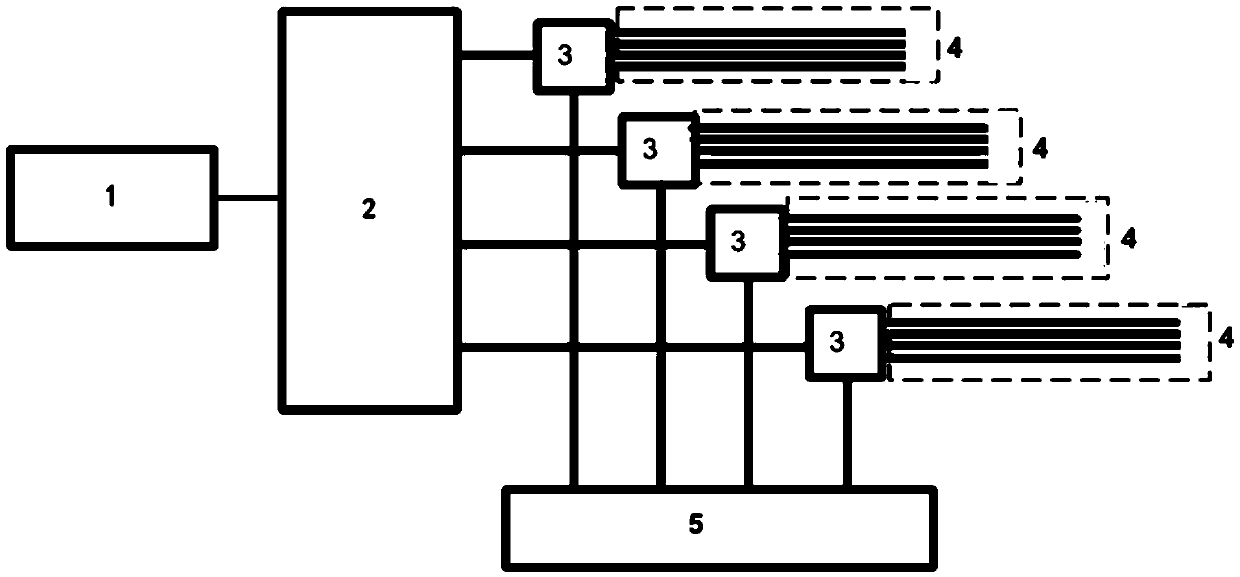

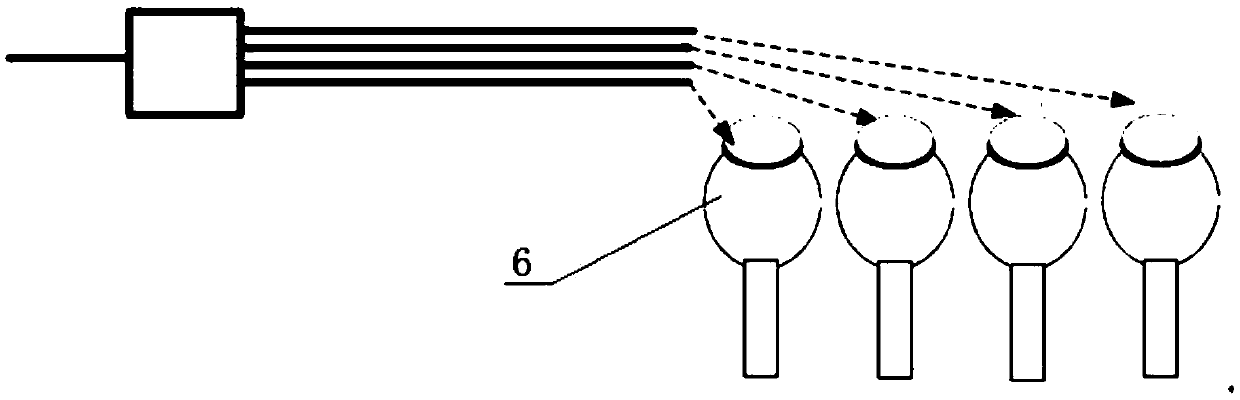

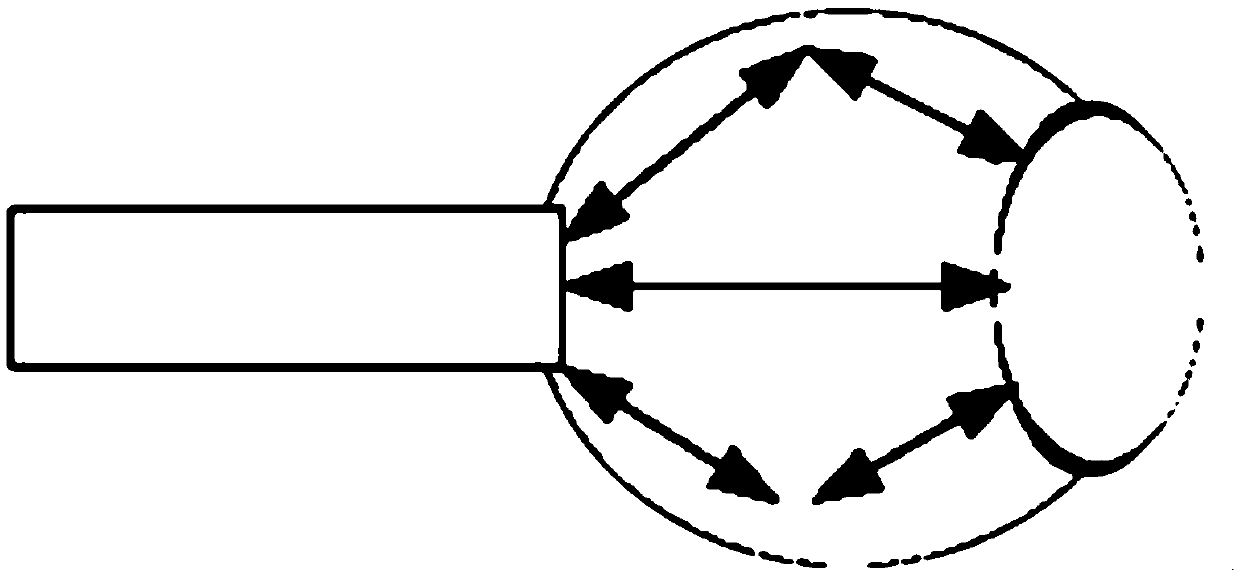

[0029] Parallel long-distance fiber optic sensing system for multiple gas refractive index detection, such as figure 1 As shown, it includes a broadband light source 1, an optical fiber splitter 2, a fiber coupler 3, an optical fiber sensor 4 and a photoelectric detection array, the broadband light source 1 is connected to the input port of the optical fiber splitter 2, and the optical fiber splitter 2 The output branch is cascaded with the input ports of a plurality of said fiber couplers 3, each of said fiber couplers 3 is connected to a fiber optic sensor 4, and each of said fiber optic sensors 4 includes a plurality of parallel fiber optic sensing probes 6; The photodetection array ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com