Anode active substance for rechargable lithum battery, manufacturing method thereof and a rechargable lithium battery containing the same

An anode active material, lithium secondary battery technology, applied in electrode manufacturing, battery electrodes, lithium storage batteries, etc., can solve problems such as capacity decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

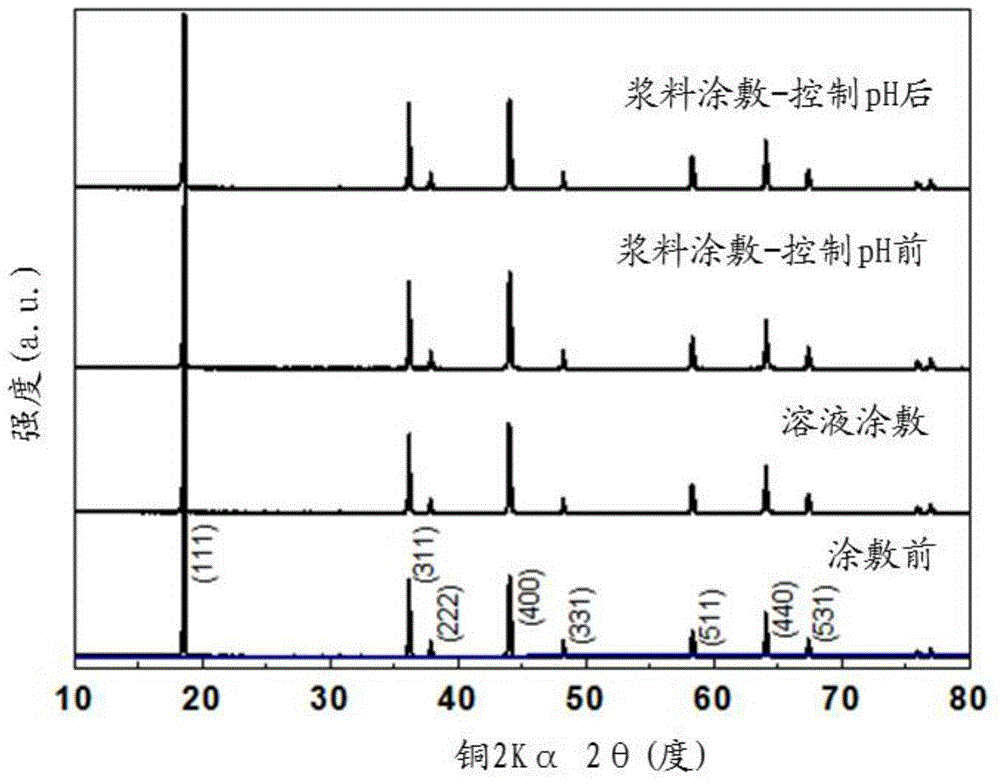

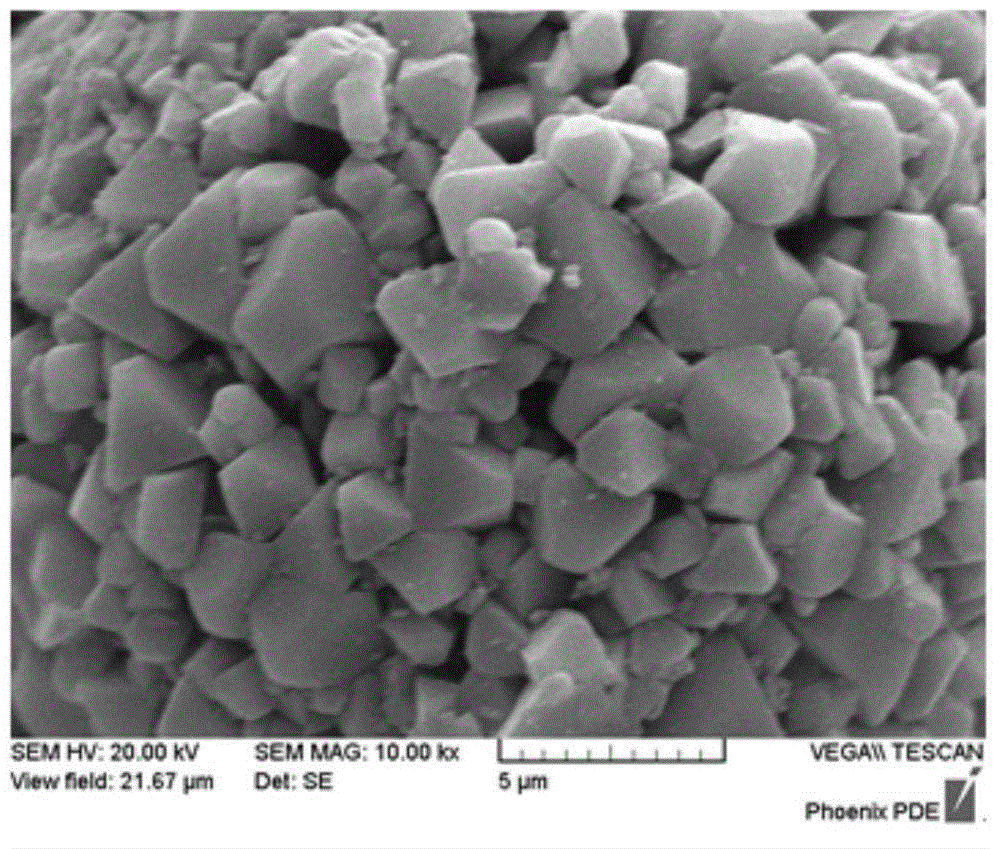

[0097] Production Example 1: A positive electrode active material (LiMn doped with Al) coated with zirconium oxyfluoride by using a slurry coating process with pH control 2 o 4 )

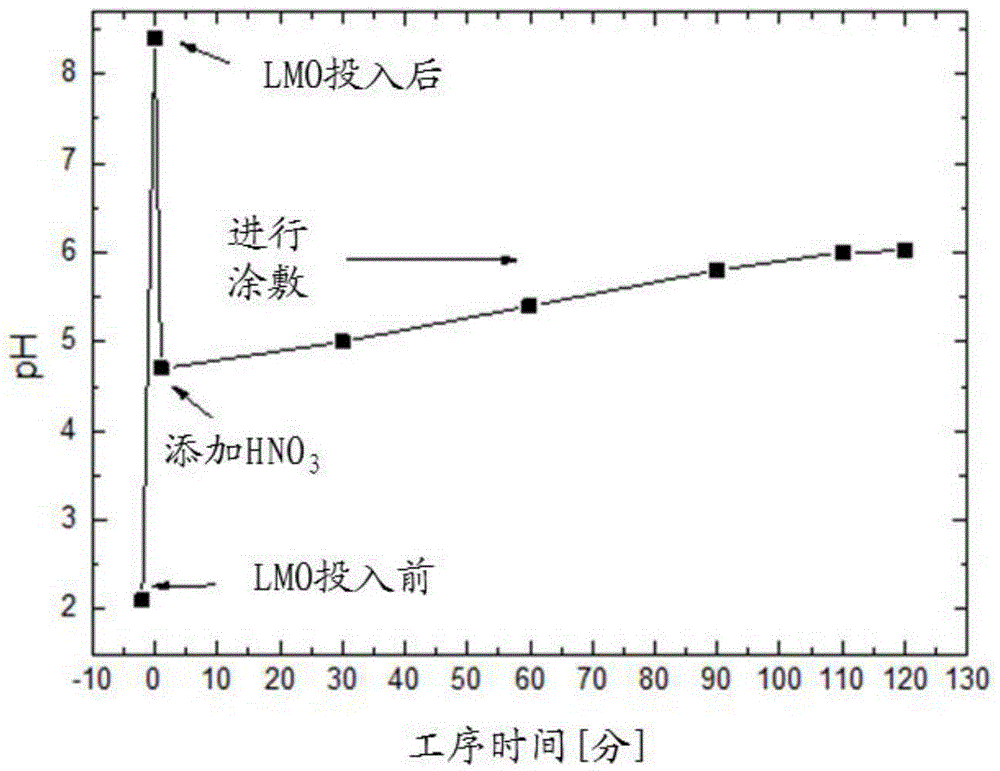

[0098] Put ZrO(NO 3 ) 2 ·xH 2 O (Kanto, 99%) was dissolved in deionized water to prepare 200 mL of a 0.005M coating solution. The coating solution was heated to 60° C. by a heater uniformly coated on the outside of the reactor. The pH at this time was 2.1. 300 g of spinel-based LMO anode active material doped with Al was put into the reactor and kept in a slurry state. With the addition of alkaline LMO powder, the pH of the coating slurry changed to alkaline 8.4. Stirring was performed to increase the dispersibility of the powder in the reactor. The stirring speed at this time was 200 rpm. For uniform distribution of the coating, pH adjustment is required, and for proper coating pH, HNO is added to the coating slurry 3 (Samchun Company, 1M) and adjust the pH to 4.7. Put NH into a 200mL pla...

Embodiment 1

[0106] The anode active material, conductive material (denkablack, Denka Company) and binder (PVDF-HFP, Kurea Company) of Production Example 1 were mixed at a ratio of 92:4:4 (wt% / wt% / wt%). Next, the mixture was uniformly applied on an aluminum foil (16 μm), dried at a temperature of 100° C., and rolled using a roll press to manufacture an electrode. At this time, the loading amount of the anode active material is 0.006g / cm 2, The rolling rate is 15.3%. A CR-2032-standard coin-type half-cell was produced using the produced anode electrode plate and PE separation membrane (16 μm, SKI Corporation) and metallic lithium as a cathode. At this time, LiPF containing 1.0 M in a mixed solvent of EC:DMC=1:1 (v / v) was used as an electrolyte 6 liquid electrolyte.

Embodiment 2

[0113] The anode active material, conductive material (denkablack, Denka Company) and binder (PVDF-HFP, Kurea Company) of Production Example 1 were mixed at a ratio of 92:4:4 (wt% / wt% / wt%). Next, the mixture was uniformly applied on an aluminum foil (16 μm), dried at a temperature of 100° C., and rolled using a roll press to manufacture an electrode. A pouch-type full battery was fabricated using the anode electrode plate, PE separation membrane (16 μm, SKI Corporation) and cathode plate thus produced. Natural graphite (PoscoChemtech Co Ltd) was used as the cathode plate, and the N / P ratio of the anode and cathode was designed to be 1.13. The manufactured full battery structure is a 3450bi-cell structure with a rated capacity of 16.0±0.5mAh (@0.2C). At this time, LiPF containing 1.0 M in a mixed solvent of EC:DMC=1:1 (v / v) was used as an electrolyte 6 liquid electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com