Clothing and method for producing a clothing

A technology for covering parts and components, which is applied in textiles and papermaking, papermaking, papermaking and other directions, can solve the problems of yarn coming out, textile surface formations unraveling, and edges are easy to open lines, etc., to prevent unraveling, reduce Small permeability, effective edge strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

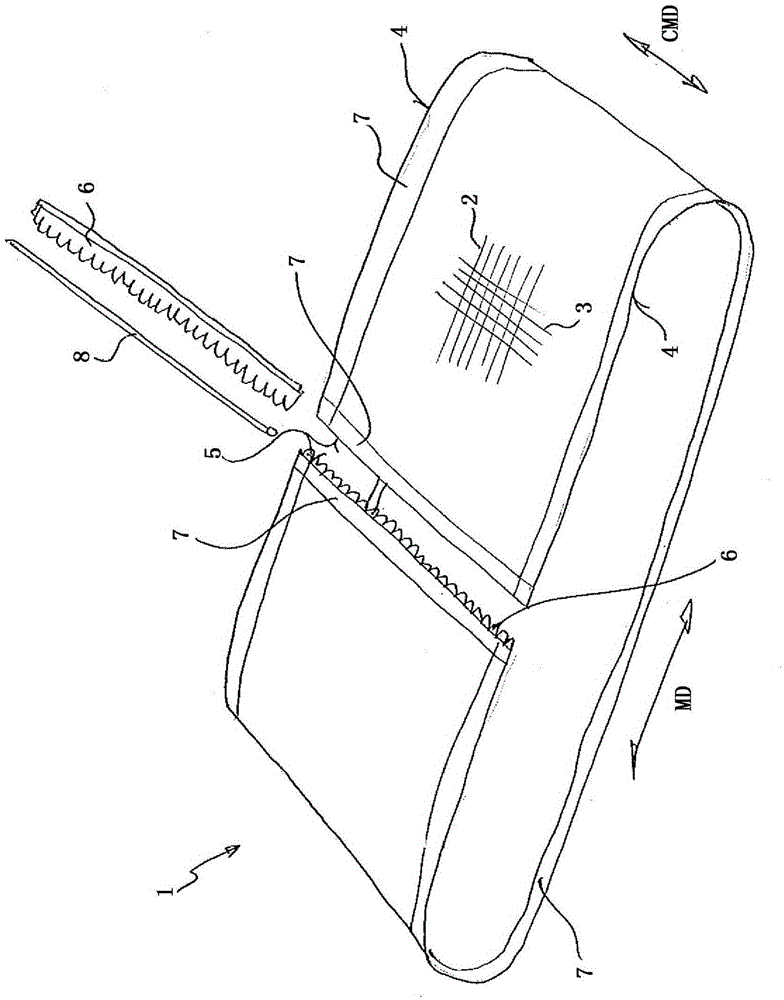

[0033] figure 1 A cover 1 is shown schematically, which can be used in particular as a drying screen in a machine for producing fibrous webs, for example paper or cardboard webs.

[0034] In the applications mentioned, woven drying screens are frequently used, as in the exemplary embodiment shown. Another embodiment can be made of helical coils, which overlap each other and are connected to each other by patch cords. Such an embodiment is not the subject of the present invention.

[0035] For clarity, figure 1 Only a part of the drying screen surface is shown as a weave of interdigitated yarns 2 , 3 . The yarns 2, 3 can be constructed in a known manner from PET, PPS, PCTA, nylon, Kevlar or similar, known and suitable materials for the application mentioned, in any desired cross-section Monofilament or multifilament.

[0036] The cover 1 is constructed in the form of a textile sheet with two edges 4 oriented in the machine direction (hereinafter referred to as MD) and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com