Hydraulic drive device

A driving device and hydraulic technology, which is applied in the direction of power device, fluid pressure actuating device, transmission device control, etc., can solve problems such as the limit of large diameter, damage to the cooling effect of hydraulic motor, etc., and achieve the effect of reducing peak pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

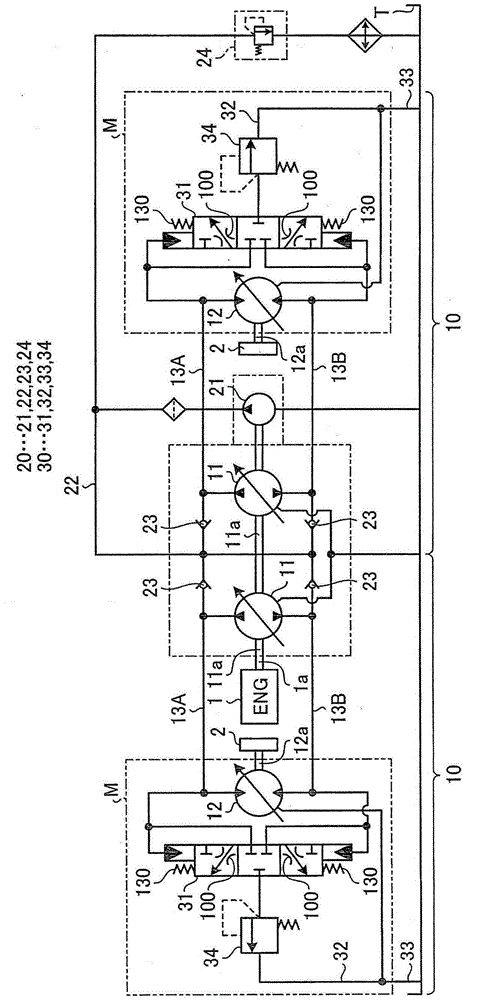

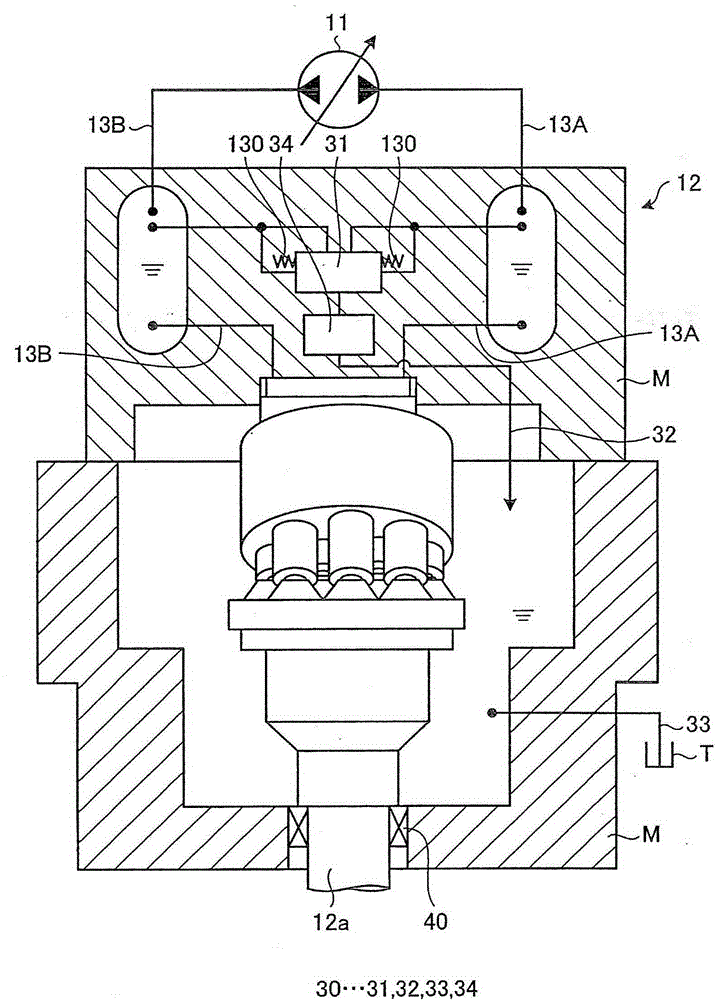

[0031] figure 1 It is a hydraulic circuit diagram showing the hydraulic drive device according to Embodiment 1 of the present invention. The hydraulic drive device illustrated here is a hydraulic drive device for driving a work vehicle used as a construction machine such as a wheel loader and a forklift, and includes an independent hydraulic transmission unit 10 between the engine 1 and the left and right drive wheels 2 . Since the hydraulic transmission unit 10 provided for each driving wheel 2 has the same structure, only one of them will be described below, and the other will be assigned the same reference numerals and its description will be omitted.

[0032] The hydraulic transmission unit 10 is also called a so-called HST (Hydro-Static Transmission), and is configured to include a hydraulic pump 11 driven by the engine 1, a hydraulic motor 12 for traveling driven by oil supplied from the hydraulic pump 11, and a hydraulic motor 12 for constituting A pair of main oil p...

Embodiment approach 2

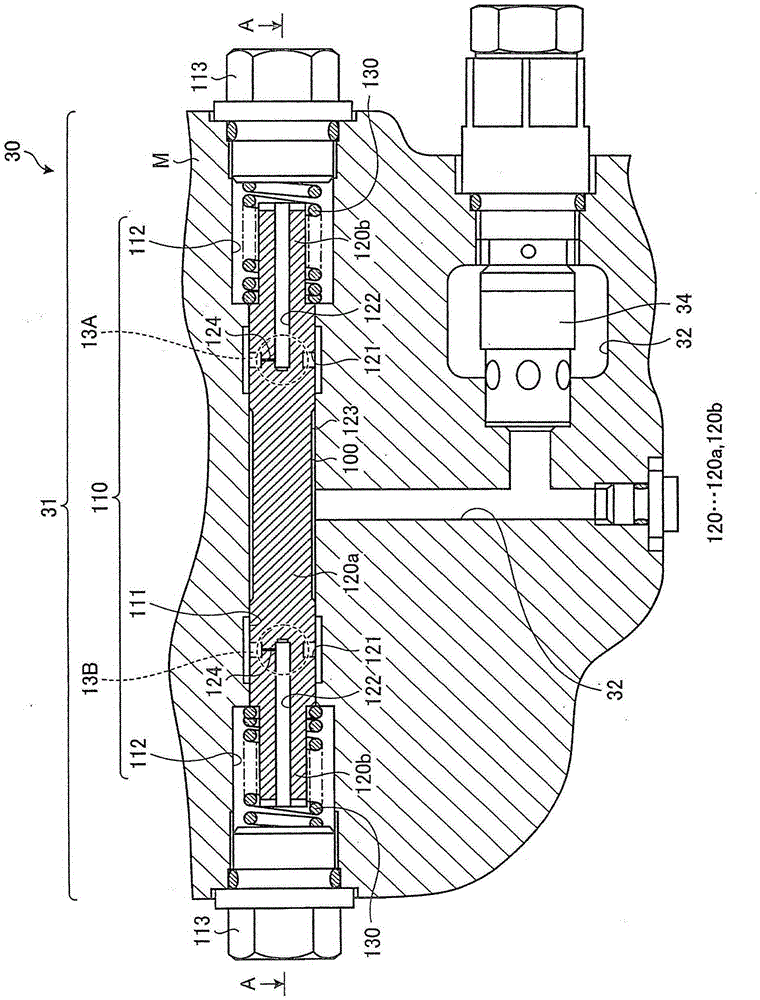

[0051] Figure 5-1 as well as Figure 5-2 Main parts of the hydraulic drive device according to Embodiment 2 of the present invention are shown. Also in this second embodiment, the low-pressure selector valve 31 is constituted by arranging the spool valve 120 in the spool valve hole 110 formed in the motor housing M similarly to the first embodiment. structure is different. That is, in Embodiment 2, the throttle portion 100 of Embodiment 1 is not formed between the slide hole portion 111 of the spool valve hole 110 and the gap forming portion 123 of the spool valve 120 , and therefore the throttle portion 100 of Embodiment 1 is formed by placing the spool valve base portion 120a outside When the diameter is D0, the outer diameter of the gap forming portion 123 is d0, and the throttle length is L0, it becomes 10.0<(δ^2)d0 / L0 (where, δ=(D0-d0) / 2), the gap forming part 123 is configured.

[0052] On the other hand, a throttle rod 210 is arranged on a straight line portion be...

Embodiment approach 3

[0057] Figure 6-1 as well as Figure 6-2 The main part of the hydraulic drive system of Embodiment 3 of this invention is shown. Also in this third embodiment, the low-pressure selector valve 31 is constituted by arranging the spool valve 120 in the spool valve hole 110 formed in the motor housing M similarly to the first embodiment. structure is different. That is, in Embodiment 3, the throttle portion 100 of Embodiment 1 is not formed between the slide hole portion 111 of the spool hole 110 and the gap forming portion 123 of the spool valve 120 , so that the spool base portion 120 a When the outer diameter is D0, the outer diameter of the gap forming part 123 is d0, and the throttle length is L0, 10.0<(δ^2)d0 / L0 (where δ=(D0-d0) / 2) The gap forming part 123 is configured.

[0058]On the other hand, in the case discharge oil passage 32 , the diameter of the straight portion with the oil-filled safety valve 34 is reduced to form a throttle portion 300 based on cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com