High-strength nonwoven fabric for picture production

A high-strength, non-woven fabric technology, which is applied in the field of non-woven fabrics and high-strength non-woven fabrics for painting, can solve the problems of complex production process, high cost, and high price, and achieve good adsorption, firm viscosity, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

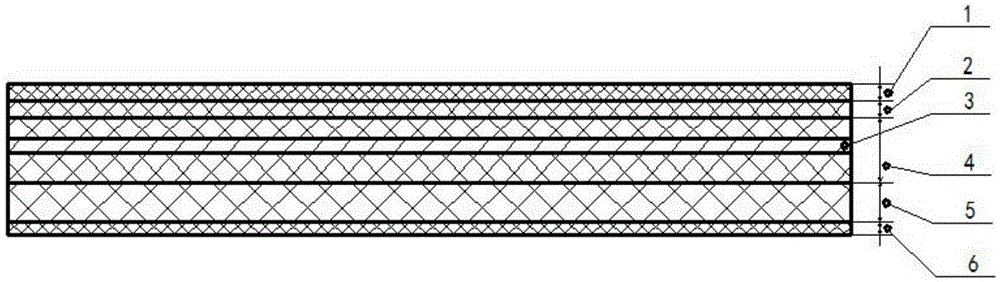

[0028] A high-strength non-woven fabric for painting, the main body of which is composed of three superimposed layers: a surface layer 2, a middle layer 4 and a back layer 5. The innovations of the present invention are:

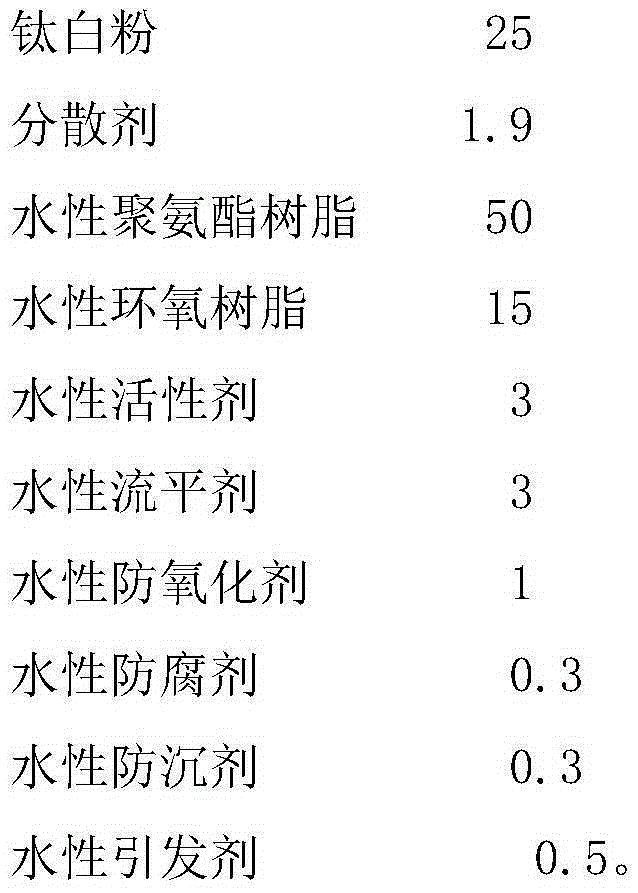

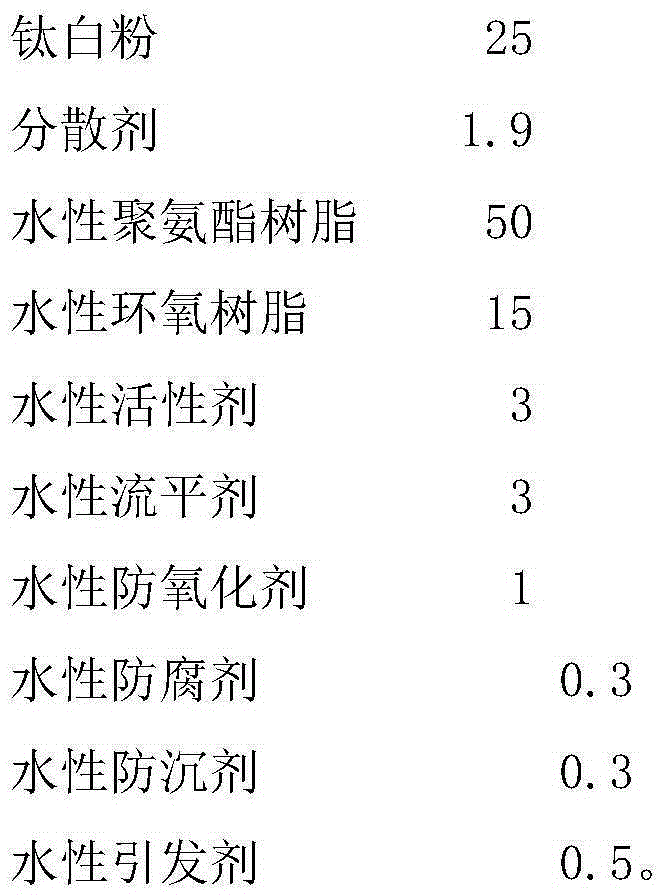

[0029] 1. A layer of high molecular polymer layer 1 is coated on the surface layer. The components and parts by weight of the polymer layer are:

[0030] Waterborne polyurethane resin 65

[0031] Water-based plasticizer 2.5

[0032] Water-based anti-sedimentation agent (stabilizer) 1.5

[0033] Water-based lubricant 1.5

[0034] Water-based leveling agent 2.0

[0035] Water-based defoamer 2.0

[0036] Water-based brightener 0.5

[0037] Matting Powder 3.5

[0039] Colorant 1.5, the above com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com