Single-layer vibration isolation system design method for power equipment

A single-layer vibration isolation system, power machinery technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as lack of design concepts and low design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The following will take a compressor as an example of power machinery equipment to further describe the details of the design method of the single-layer vibration isolation system for power machinery equipment according to the present invention.

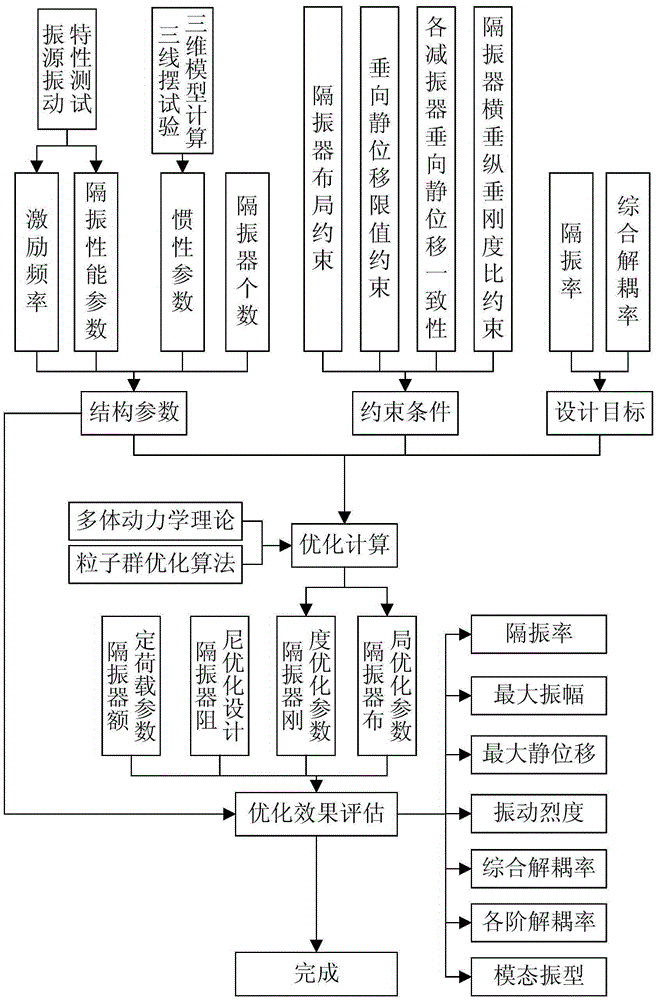

[0067] Such as figure 1 As shown, the steps of the single-layer vibration isolation system design method for compressors in this embodiment include:

[0068] 1) Test the vibration characteristics of the vibration source of the compressor to obtain the excitation frequency f and vibration isolation performance parameters of the vibration source;

[0069] 2) Obtain the inertial parameters of the compressor;

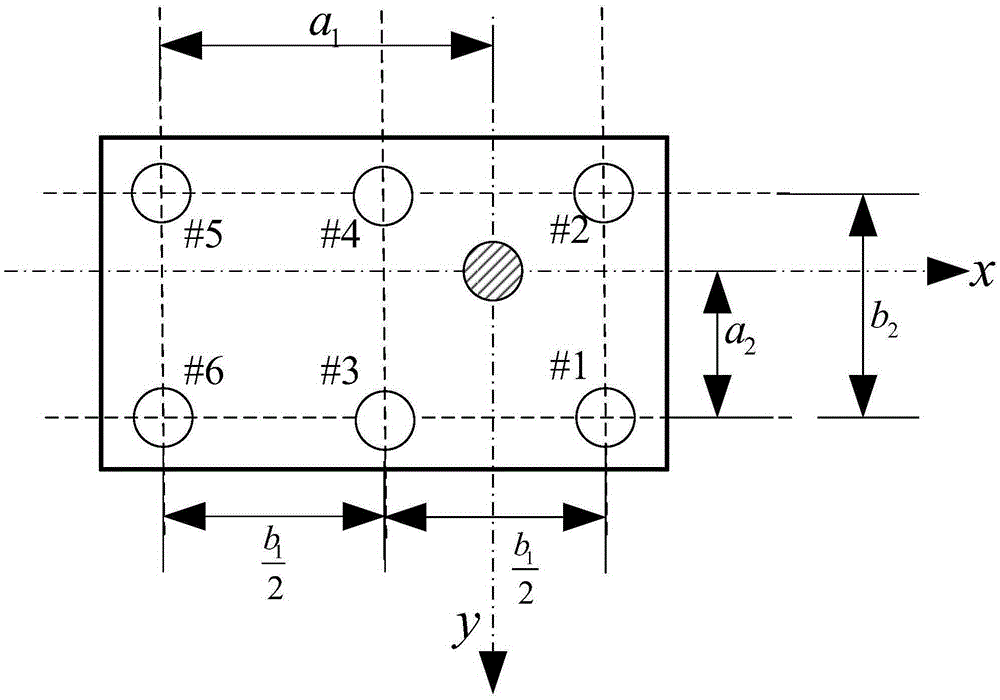

[0070] 3) Determine the number n of vibration isolators in the single-layer vibration isolation system;

[0071] 4) According to the actual engineering design environment of the compressor, the constraints for the design of the single-layer vibration isolation system are determined. The constraints include the layout cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com