Output power regulation method of solid oxide fuel cell

A technology of solid oxide and output power, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of wasting electric energy and waste, and achieve the effects of reducing fuel consumption, improving effective utilization rate, and extending effective service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

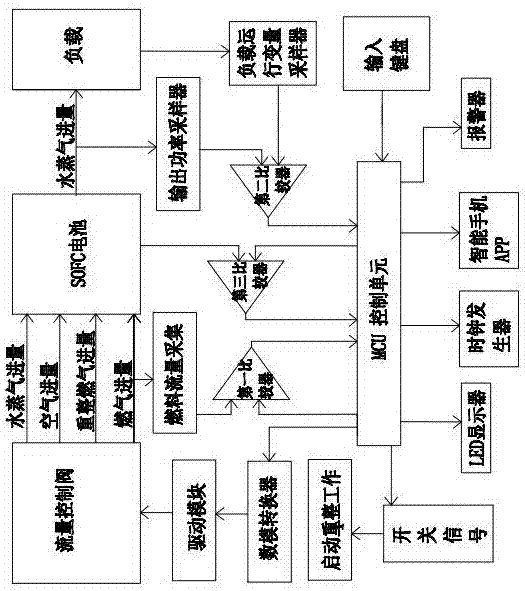

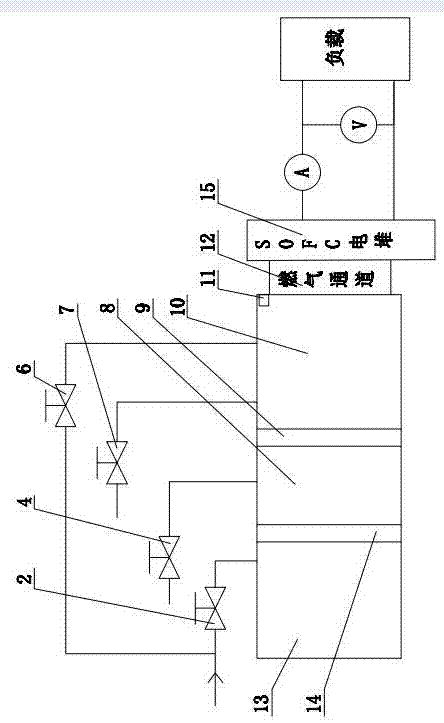

[0047] Such as figure 1 and figure 2 As shown, it is a method for adjusting the output power of a solid oxide fuel cell, including a solid oxide fuel cell and a control unit, and the solid oxide fuel cell includes a combustion processing chamber, a gas channel 12 and an SOFC stack 15, wherein The combustion processing chamber includes a gas storage chamber 13, a combustion chamber 8 and a reforming chamber 10, the gas storage chamber 13, the combustion chamber 8 and the reforming chamber 10 are sequentially connected in series, and between the gas storage chamber 13 and the combustion chamber 8 A first air-permeable partition 14 is provided, a second air-permeable partition 9 is provided between the combustion chamber 8 and the reforming chamber 10, the gas inlet of the gas channel 12 communicates with the gas outlet of the reforming chamber 10, and the gas channel 12 The gas outlet of the gas outlet communicates with the gas inlet of the SOFC stack 15; in the present embodi...

Embodiment 2

[0066] Such as figure 1 and figure 2As shown, it is a method for adjusting the output power of a solid oxide fuel cell, including a solid oxide fuel cell and a control unit, and the solid oxide fuel cell includes a combustion processing chamber, a gas channel 12 and an SOFC stack 15, wherein The combustion processing chamber includes a gas storage chamber 13, a combustion chamber 8 and a reforming chamber 10, the gas storage chamber 13, the combustion chamber 8 and the reforming chamber 10 are sequentially connected in series, and between the gas storage chamber 13 and the combustion chamber 8 A first air-permeable partition 14 is provided, a second air-permeable partition 9 is provided between the combustion chamber 8 and the reforming chamber 10, the gas inlet of the gas channel 12 communicates with the gas outlet of the reforming chamber 10, and the gas channel 12 The gas outlet of the gas outlet communicates with the gas inlet of the SOFC stack 15; in the present embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com