Casting process for forming complex pipeline in titanium alloy investment casting

A casting process, titanium alloy technology, applied in the directions of casting mold components, manufacturing tools, casting molding equipment, etc., can solve the problems of easy core fracture, eccentric core, cracking, titanium tube oxidation, etc., to ensure surface quality, overcome cleaning Difficulty, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

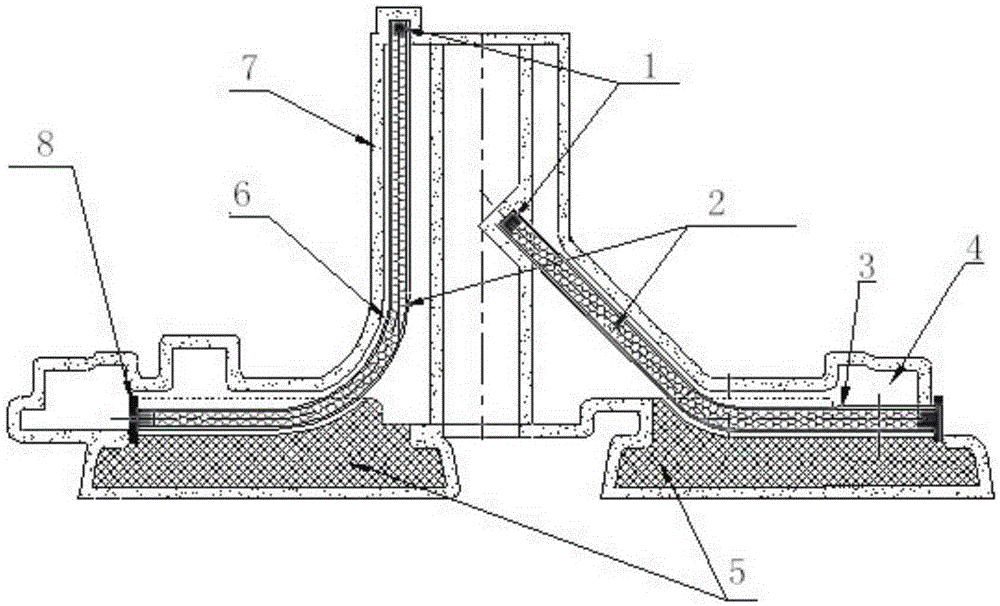

[0019] 5. If figure 1 Shown is the implementation process of forming oil pipe 6 and air pipe 3 in the pipeline,

[0020] (1) Make the air pipe 3 and the oil pipe 6 into the shape shown in the figure, fill the air pipe 3 and the oil pipe 6 with 100 mesh yttrium oxide sand, and block the pipe mouth with water glass mixed with bauxite mud; prevent the slurry from infiltrating inside the pipe.

[0021] (2) Type the pipeline, make the main body wax mold with the trachea 3 cavity and the casting body, make the split wax mold and the cover wax mold 5 containing the oil pipe 6 cavity and the bonding wax mold; There is a positioning core head to prevent the titanium tube from being eccentric under the impact force and centrifugal force of the molten metal;

[0022] (3) bonding the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com