A kind of gradient honeycomb composite body and its manufacturing method and application structure

A technology of application structure and manufacturing method, applied in the sub-structure, super-structure, super-structure sub-assembly and other directions, can solve the problems of poor energy absorption function, disadvantage of lightweight structure, etc., and achieve low cost, high material utilization rate, and easy batch production. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

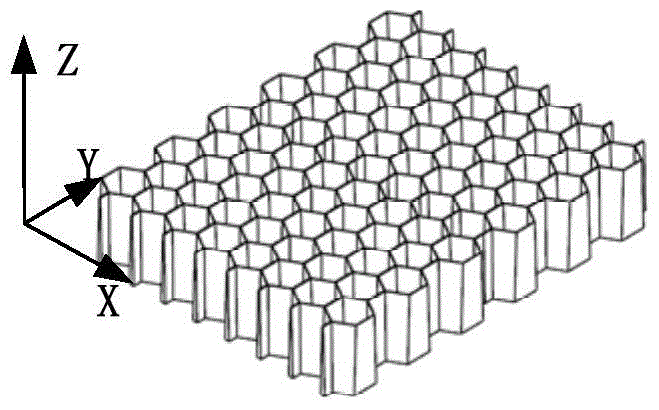

[0063] The invention provides a gradient honeycomb composite body, which is a vertical gradient honeycomb composite body, and its structure is as follows: figure 1 As shown in Figure 3, it includes: a plurality of cell units.

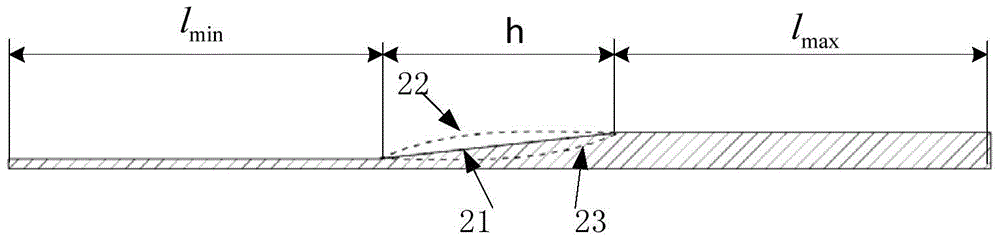

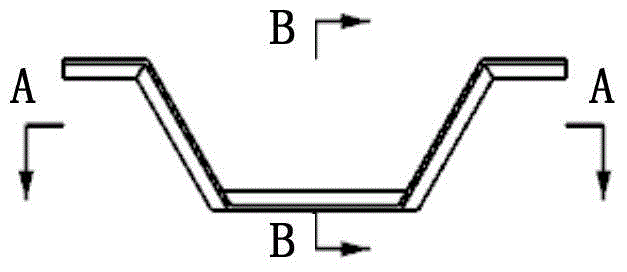

[0064] The cross section of the unit cell can be a hollow polygon or a hollow circle. After the gradient honeycomb composite is cut along the plane where the X-axis and Y-axis are located, the thickness of multiple cells in the same section is the same; along the direction of the Z-axis, the thickness of each cell is changed, such as figure 2 As shown, they are thin area, thick area and variable thickness area respectively, and the corresponding lengths are l min , l max And h, the thin area and the thick area are equal thickness areas, and the thickness of a certain point x in the thickening area is calculated according to the following power exponent function:

[0065]

[0066] Among them, t a is the thickness value corresponding to the thin a...

Embodiment 2

[0076] The invention provides a gradient honeycomb composite body, which is a horizontal gradient honeycomb composite body, and its structure is as follows: Figure 5 As shown, it includes: a plurality of cell monomers, and the cross section of the cell monomers can be a hollow polygon or a hollow circle. After intercepting the gradient honeycomb composite body along the plane where the X-axis and Z-axis are located, the gradient honeycomb composite body is divided into multiple thickness regions in the in-plane direction, and the number of cell monomers contained in each thickness region is the same; and Along the Y direction, the wall thickness of the cell monomers in the same thickness area is the same.

[0077] The thickness of the different thickness regions increases according to the gradient function:

[0078]

[0079] where 11 is the thickness of the minimum thickness region, t n is the thickness of the maximum thickness region; i is the i-th thickness region, n i...

Embodiment 3

[0088] The present invention also provides an applied structure of a gradient honeycomb composite body, the structure of which is as follows: Figure 7 As shown, it includes a gradient honeycomb composite body 62 and a pipe 61 wrapping it. Therefore, it is also called gradient honeycomb filled thin-walled tube structure. The gradient honeycomb composite body 62 is a longitudinally gradient honeycomb composite body, and may also be a transversely gradient honeycomb composite body; the pipes therein are made of high-strength fiber-reinforced composite materials.

[0089] The manufacturing process of the above application structure is as follows:

[0090] Step 31, select the gradient honeycomb composite body with the required gradient value according to the design requirements, and process the selected gradient honeycomb composite body into the required shape by wire cutting method;

[0091] Step 32, laying the preformed plate of high-strength fiber-reinforced composite materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com