Finished brick clamp

A fixture and bricklaying technology, which is applied in the direction of load hanging components, track systems, traveling mechanisms, etc., to achieve the effects of ingenious overall structure design, reduced labor intensity, and large lifting weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

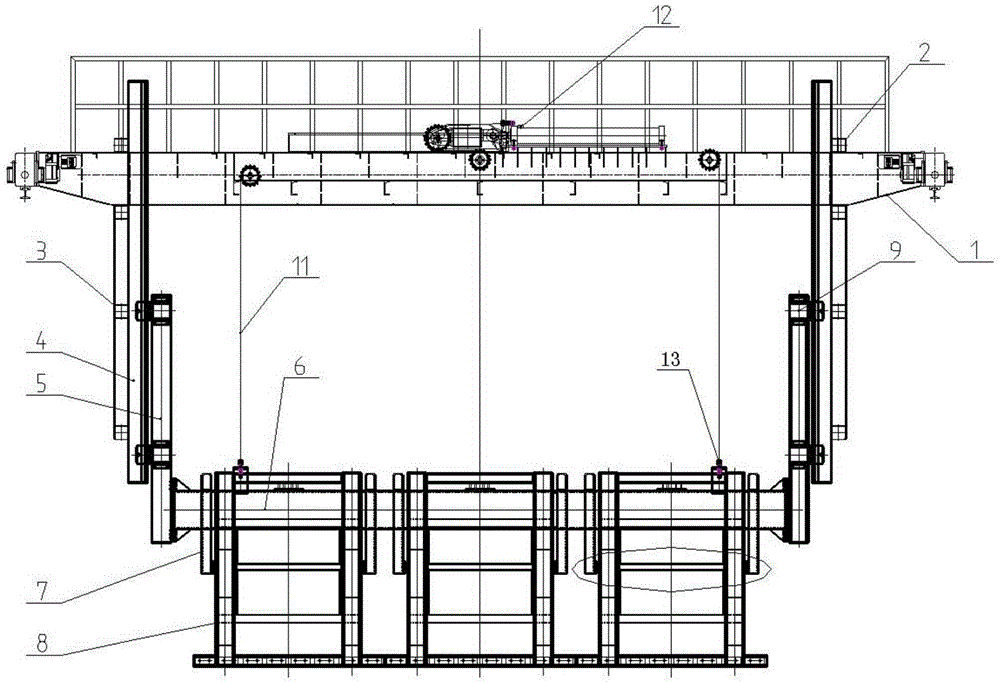

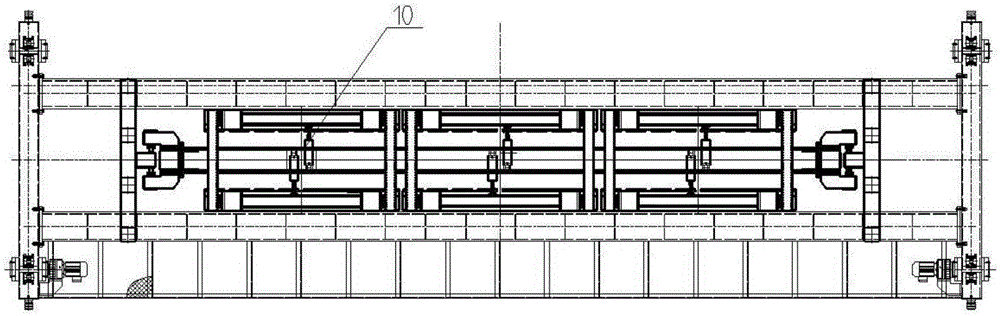

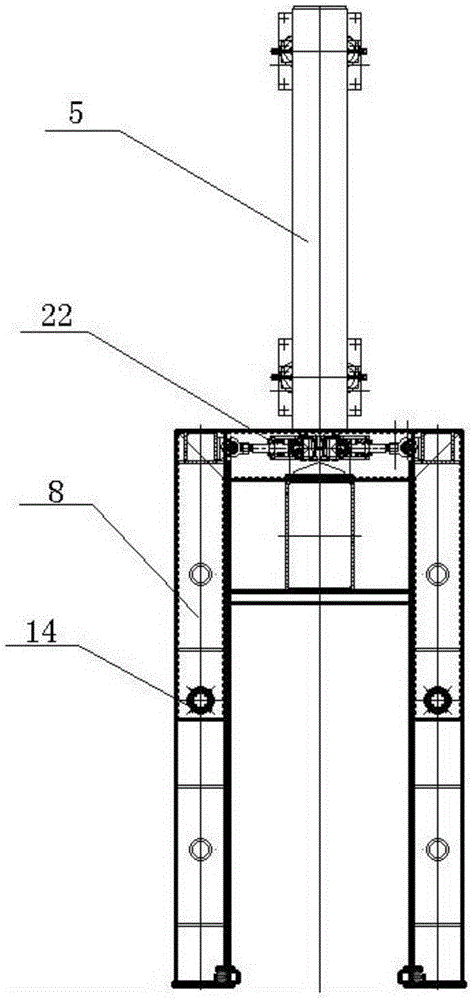

[0029] Such as Figure 1-4As shown, it is a finished bricklaying jig proposed by the present invention, including a traveling mechanism 1, a crossbeam 2, a lifting mechanism 12 and a fixture frame. shaft and bearings. The crossbeam 2 is welded on the running gear 1 for strengthening the lifting mechanism 12 , and the lifting mechanism 12 is arranged at the middle position of the top of the running gear 1 . Be welded with track beam 4 on crossbeam 2, be connected with moving beam 5 by 8 block pulleys 9 slides on track beam 4, and moving beam 5 can move up and down on track beam 4. A fixture frame installation crossbeam 62 is fixedly installed on the lower part of the moving beam 5, and three fixture frames are fixedly installed on the fixture frame installation crossbeam 62, and each fixture frame includes two fixture outer frames 7 and a pair of fixture inner frames 8, so The fixture outer frame 7 is fixedly welded on the fixture frame mounting beam 62 , the fixture inner fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com