Preparation method of needle punched non-woven fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

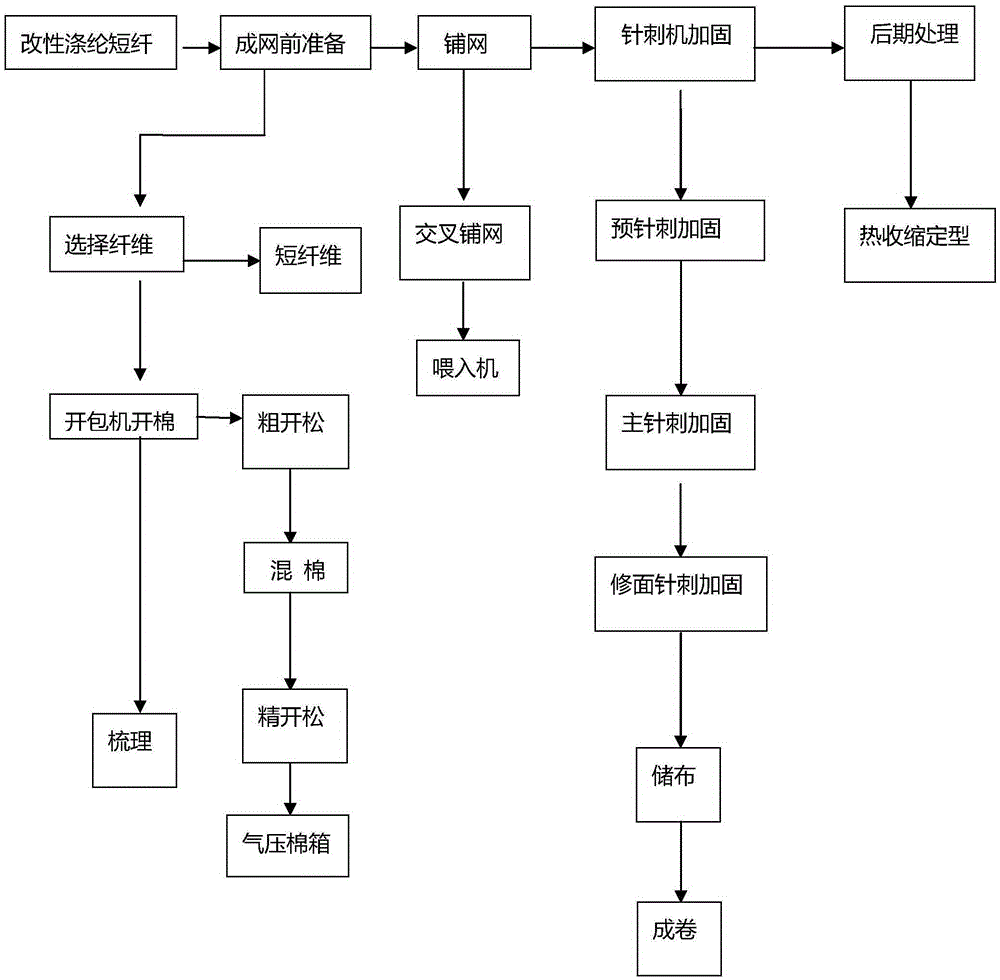

Image

Examples

Embodiment 1

[0049] The preparation method of described acupuncture nonwoven specifically comprises the following steps:

[0050] A. Preparation of modified polyester staple fiber

[0051] Blend polyester chips, flame retardants, dispersing lubricants and auxiliary materials at a ratio of 89%, 4%, 3%, and 4%, extrude and filter through a twin-screw extruder, and pass through a spinning box, a metering pump, and a spinneret Spinning, then cooling and clustering, one or more times of heating and drawing, and finally shaping, winding, cutting and packaging;

[0052] B. Preparation of needle-punched nonwovens

[0053] 1) Preparation before forming a net

[0054] ①Choose fiber

[0055] According to the requirements of product performance, select 2D*51mm, 2.5D*51mm and the modified polyester staple fiber POY made in A, and weigh, open and mix according to the ratio of 40%, 50%, and 10%;

[0056] ②The bale opener opens the cotton

[0057] a. Rough opening process

[0058] Use three weighing...

Embodiment 2

[0086] The preparation method of described acupuncture nonwoven specifically comprises the following steps:

[0087] A. Preparation of modified polyester staple fiber

[0088] Blend polyester chips, flame retardants, dispersing lubricants and auxiliary materials in a twin-screw extruder at a ratio of 85%, 8%, 3%, and 4%, and extrude and filter, wherein the amount of flame retardant added is the blend 8% of the total mass is sprayed through the spinning box, metering pump and spinneret, then cooled and clustered, heated and drawn once or more, and finally shaped, wound, cut and packaged;

[0089] B. Preparation of needle-punched nonwovens

[0090] 1) Preparation before forming a net

[0091] ①Choose fiber

[0092] According to the requirements of product performance, select 2D*51mm, 2.5D*51mm and the modified polyester staple fiber POY made in A, and weigh, open and mix according to the ratio of 40%, 50%, and 10%;

[0093] ②The bale opener opens the cotton

[0094] a. Roug...

Embodiment 3

[0123] The preparation method of described acupuncture nonwoven specifically comprises the following steps:

[0124] A. Preparation of modified polyester staple fiber

[0125] Blend polyester chips, flame retardants, dispersing lubricants and auxiliary materials in proportions of 81%, 12%, 3%, and 4%, extrude and filter through a twin-screw extruder, and pass through a spinning box, a metering pump, and a spinneret Spinning, then cooling and clustering, one or more times of heating and drawing, and finally shaping, winding, cutting and packaging;

[0126] B. Preparation of needle-punched nonwovens

[0127] 1) Preparation before forming a net

[0128] ①Choose fiber

[0129] According to the requirements of product performance, select 2D*51mm, 2.5D*51mm and the modified polyester staple fiber POY made in A, and weigh, open and mix according to the ratio of 50%, 40%, and 10%;

[0130] ②The bale opener opens the cotton

[0131] a. Rough opening process

[0132] Use three wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com