Embedded bottle pre-form detection system and detection method

A detection system and detection method technology are applied in the field of embedded preform detection systems, which can solve the problems of fast and high-precision detection of difficult PET preforms, inefficient manual detection methods, and high false detection rate, and achieve a reduction in the entire liquid line. Loss, reduction in seal failure rate, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in combination with specific embodiments.

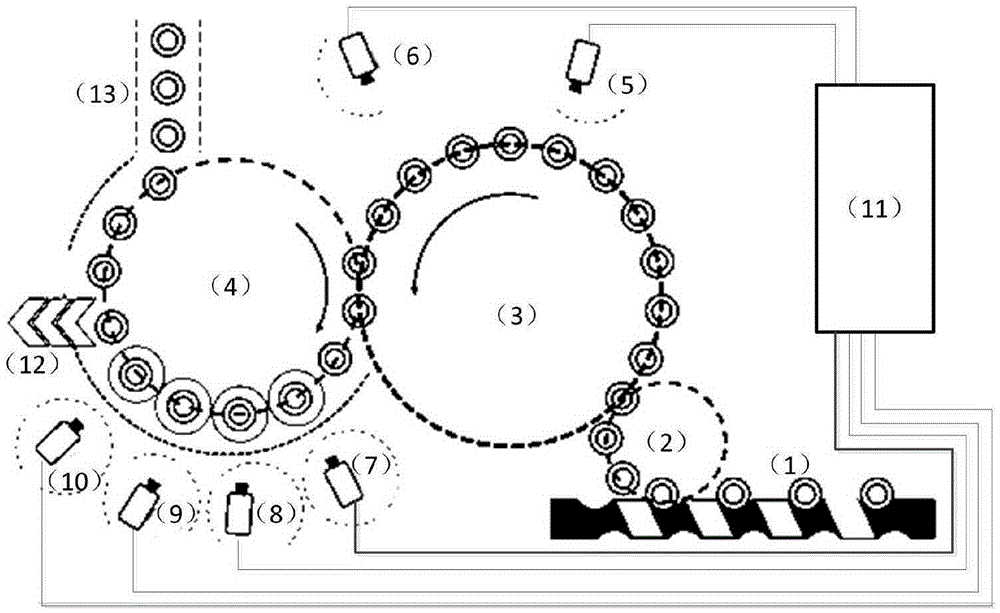

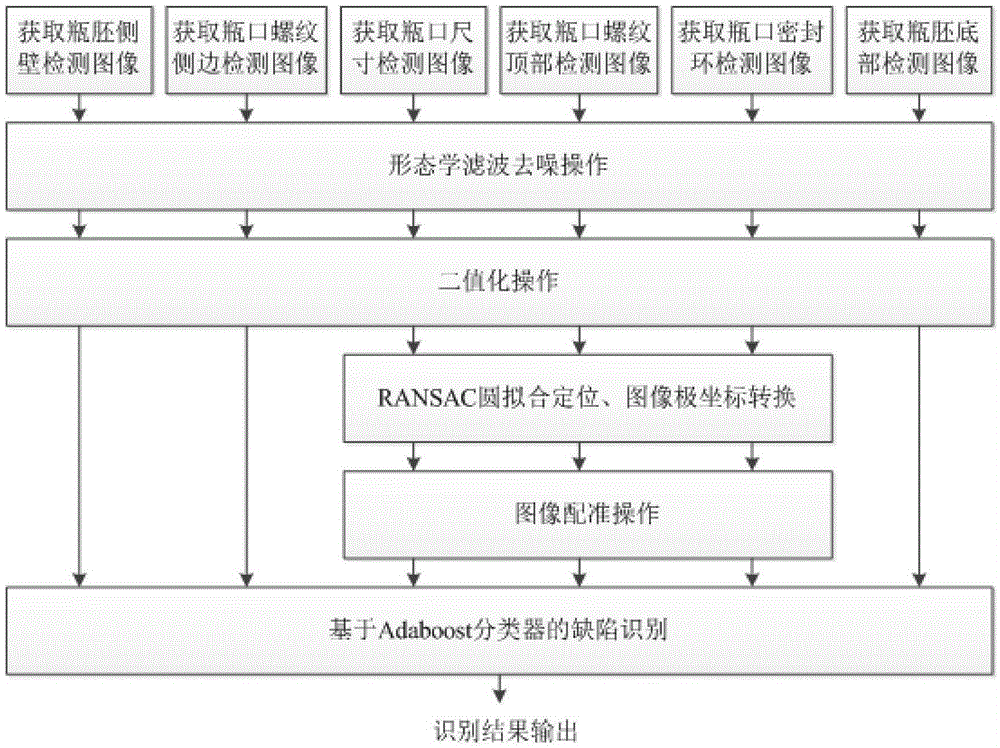

[0038] The structure of the embedded preform detection system of the present invention is as follows: figure 1 As shown, the preform unscrambling device 1 is used to arrange and untangle the preforms after injection molding, and send the preforms to the input turntable 2, and the rotation of the input turntable 2 drives the preforms to enter the first detection turntable 3, and the first detection turntable 3 A preform side wall detection camera 5 and a bottle mouth thread side detection camera 6 are installed beside the preform delivery track. The first detection turntable 3 sends the preforms on the track to the second detection turntable 4, and the second detection turntable 4 Next to the delivery track, there are bottle mouth size inspection cameras 7, bottle mouth thread top inspection cameras 8, bottle mouth sealing ring inspection cameras 9, and preform bottom insp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com