Reconstructive peeping prevention optical PUF

An optical and media technology, applied in the field of reconfigurable and anti-spying optical PUF, can solve the problems of not being able to prevent anti-spying optical PUF, difficult optical PUF reconstruction behavior, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

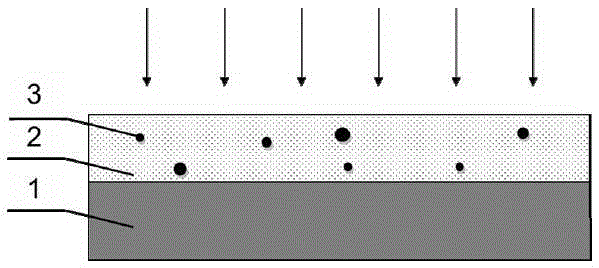

[0026] A reconfigurable and spy-proof optical PUF designed for 500nm wavelength response.

[0027] This optical PUF as figure 1 As shown, the specific structure fabrication process is as follows:

[0028] 1. The substrate is made of gemstones with a thickness of 160 microns.

[0029] 2. Mix ZnO and demineralized water to prepare a ZnO dispersion with a volume fraction of 5% and a nanometer particle size of 200nm. A magnetic stirrer was used to stir and disperse at a rotation speed of 1000 rpm for 1 hour, and then ultrasonicated for 10 minutes to prevent the ZnO nanoparticles from aggregating.

[0030] 3. Place the gemstone substrate on a 45° inclined plate, use a professional spray gun to spray the ZnO nanoparticle dispersion, and control the thickness of the nano-media through the spraying time.

[0031] 4. Place it horizontally at room temperature for one day and wait for the ZnO dielectric layer to solidify and form.

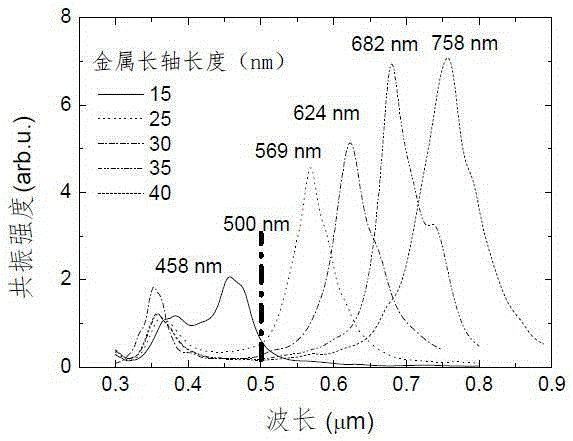

[0032] 5. Afterwards, configure the ellipsoidal sil...

Embodiment 2

[0037] A reconfigurable and spy-proof optical PUF designed for 620nm wavelength response.

[0038] This optical PUF as figure 1 As shown, the specific structure fabrication process is as follows:

[0039] 1. Quartz glass with a thickness of 200 microns can be used as the substrate.

[0040] 2. Mix GaP and demineralized water to prepare a GaP dispersion with a volume fraction of 5% and a nanometer particle size of 200nm. Afterwards, the ellipsoidal silver nanoparticle dispersion is configured, and the particle diameters are fixed at 10 nm with the lengths of the two minor axes, and the lengths of the major axes are respectively 15 nm, 20 nm, 25 nm, 35 nm, and 40 nm. The volume of the dispersion is 1%. Mix it with GaP dispersion. A magnetic stirrer was used to stir and disperse at a rotation speed of 1000 rpm for 1 hour, and then ultrasonicated for 10 minutes to prevent aggregation of silver nanoparticles and GaP nanoparticles.

[0041] 3. Place the gemstone substrate on a ...

Embodiment 3

[0046] A reconfigurable and spy-proof optical PUF designed for 680nm wavelength response.

[0047] This optical PUF as figure 1 As shown, the specific structure fabrication process is as follows:

[0048] 1. A silicon wafer with a thickness of 160 microns can be used as the substrate.

[0049] 2. Put TiO 2 Mix with demineralized water to configure TiO with a volume fraction of 5% and a nanoparticle size of 200nm 2 Dispersions. Afterwards, the ellipsoidal silver nanoparticle dispersion liquid is configured, and the particle diameters are fixed at 10 nm with the lengths of the two minor axes, and the lengths of the major axes are respectively 15, 20, 25, 30, and 40 nm. The volume of the dispersion is 1%. TiO 2 The dispersion is mixed. Use a magnetic stirrer to stir and disperse at a speed of 1000rpm for 1 hour, and then ultrasonic for 10 minutes to prevent silver nanoparticles and TiO 2 Nanoparticle aggregation.

[0050] 3. Place the gemstone substrate on a 45° inclined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com