Epitaxial wafer for triode and preparation method thereof

A technology of epitaxial wafers and triodes, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as easy breakdown, high dislocation density, high leakage current of triode electronic devices, and achieve high breakdown voltage , good crystal quality and low leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art.

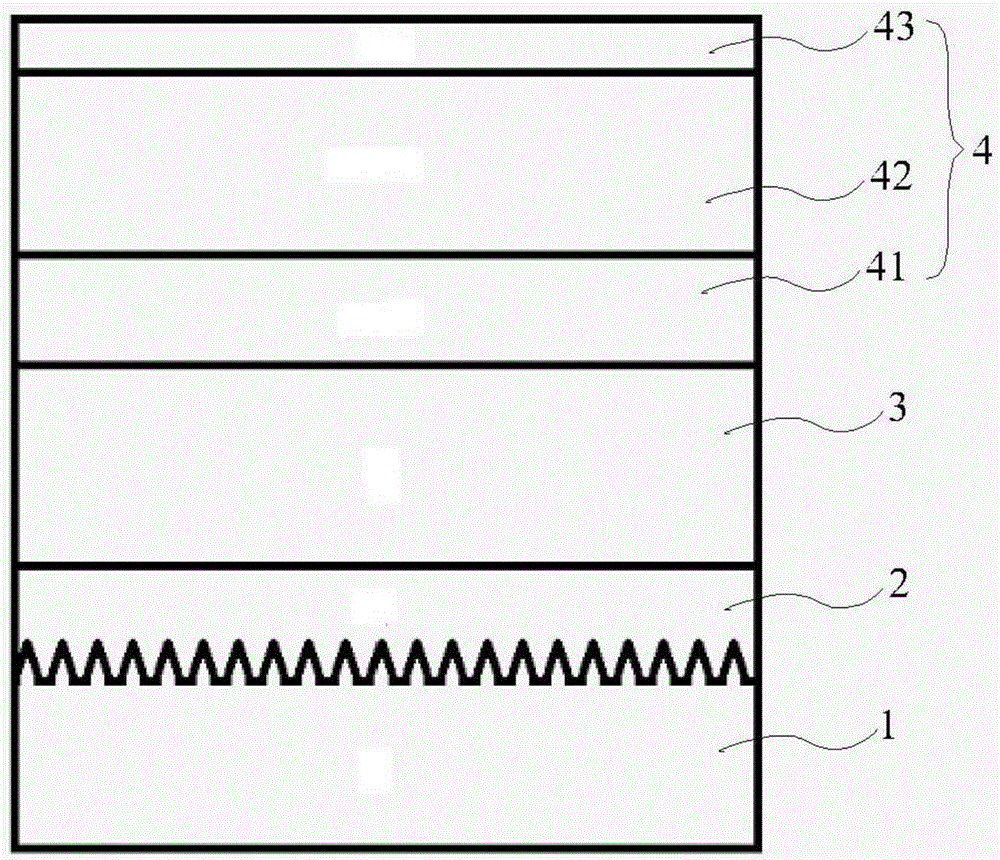

[0027] figure 1 Shown is an epitaxial wafer for a tertiary tube of the present invention. combine figure 1 As shown, the triode epitaxial wafer includes a substrate 1 , a GaN nucleation layer 2 , a GaN buffer layer 3 , a GaN channel layer 41 , an InAlN intrinsic layer 42 , and a GaN capping layer 43 stacked in sequence.

[0028] The substrate 1 is a patterned sapphire substrate (PSS) 1 . The pattern height, width, and gap of the patterned sapphire substrate 1 are 1.6 μm, 2.4 μm, and 0.6 μm respectively; or, the pattern height, width, and gap of the patterned sapphire substrate 1 are 1.7 μm, 2.6 μm, and 0.4 μm, respectively; Or, the pattern height, width, and gap of the patterned sapphire substrate 1 are 1.2 μm, 1.8 μm, and 0.1 μm, respectively.

[0029] The n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com