SHJ solar cell double-layer TCO film structure and preparation method thereof

A solar cell and thin film structure technology, applied in the field of solar cells, can solve problems such as difficult to break through the performance limit of a single-layer TCO thin film, reduce performance, etc., and achieve the effects of short-circuit current, reduced grain boundary scattering, and good work function matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

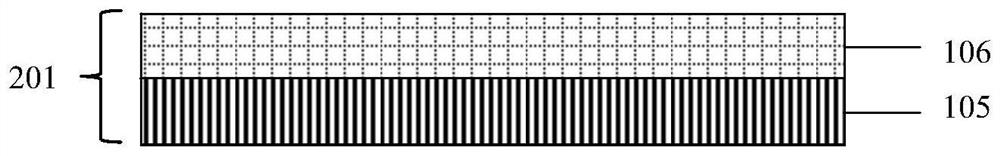

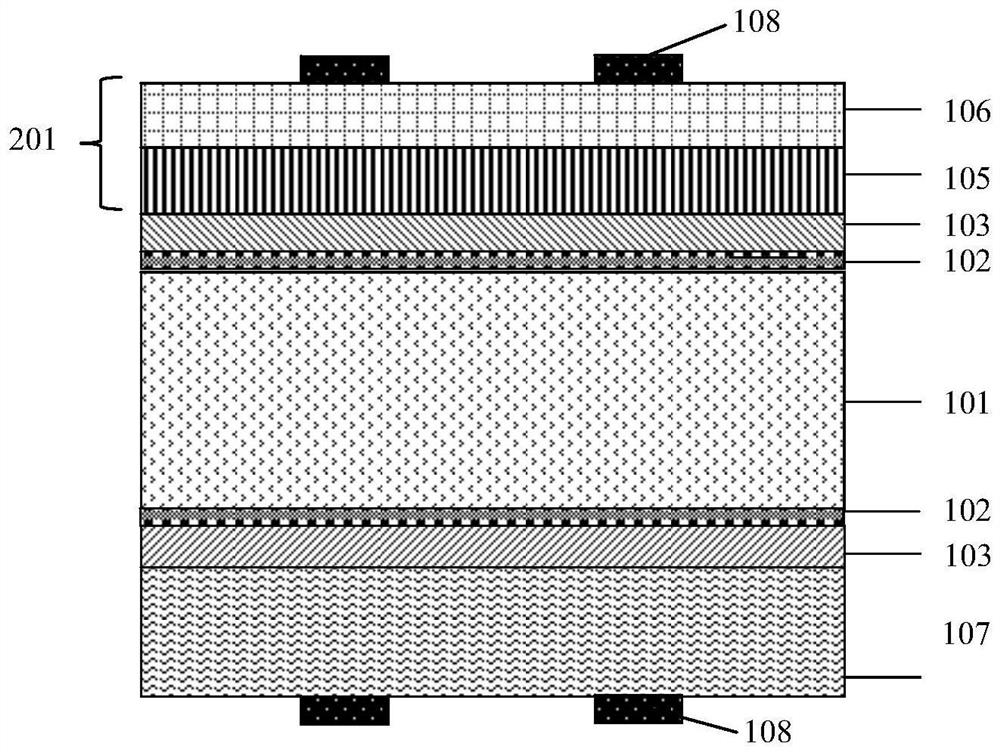

[0031] refer to figure 1 , figure 2 , using the radio frequency magnetron sputtering method to deposit a layer of double-layer TCO film 201 with a specific superposition structure on the front of the SHJ solar cell, the specific operation method includes the following steps:

[0032] (1) cleaning and texturizing the n-type monocrystalline silicon wafer to obtain a clean silicon wafer substrate with a pyramid structure on the surface;

[0033] (2) Depositing a layer of intrinsic amorphous silicon film passivation layer respectively on the front and back sides of the silicon wafer;

[0034] (3) Continue depositing one deck of n-type doped amorphous silicon film on the front side of the silicon wafer, and continue depositing one deck of p-type doped amorphous silicon film on the back side;

[0035] (4) Deposit a single-layer TCO film on the back side of the silicon wafer, i.e. on the p-type amorphous silicon film; on the front side of the silicon wafer, i.e. on the n-type amo...

Embodiment 2

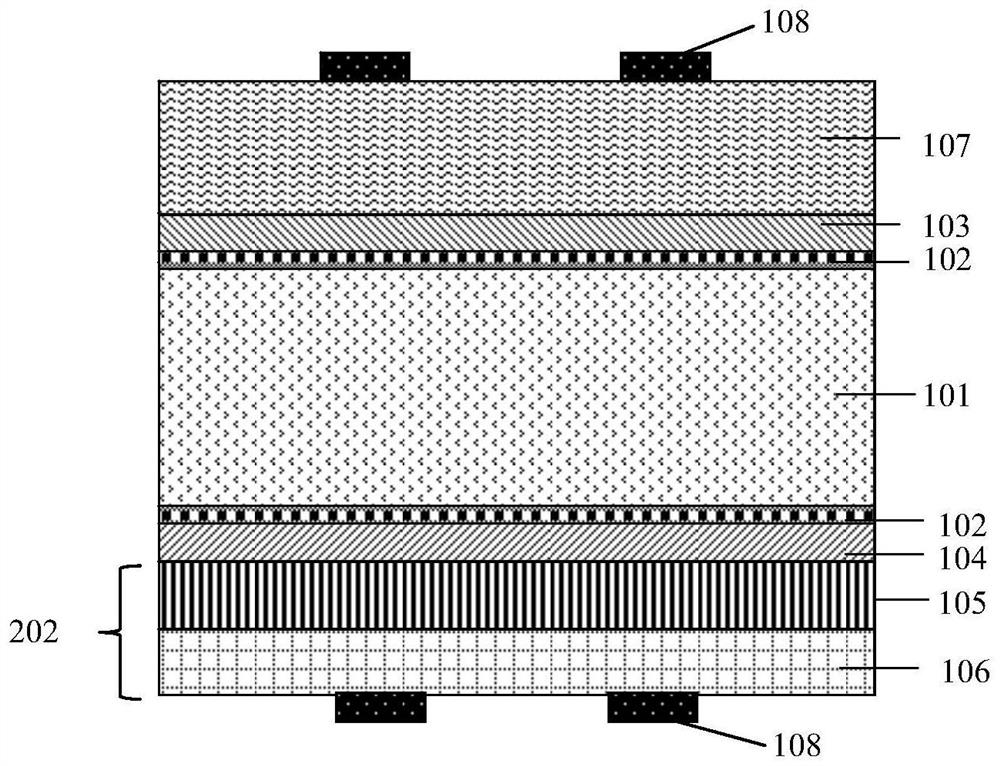

[0044] refer to figure 1 , image 3 , using the radio frequency magnetron sputtering method to deposit a layer of double-layer TCO film 202 with a specific superposition structure on the back of the SHJ solar cell, the specific operation method includes the following steps:

[0045] (1) cleaning and texturizing the n-type monocrystalline silicon wafer to obtain a clean silicon wafer substrate with a pyramid structure on the surface;

[0046] (2) Depositing a layer of intrinsic amorphous silicon film passivation layer respectively on the front and back sides of the silicon wafer;

[0047] (3) Continue depositing one deck of n-type doped amorphous silicon film on the front side of the silicon wafer, and continue depositing one deck of p-type doped amorphous silicon film on the back side;

[0048] (4) Deposit a single-layer TCO film on the front side of the silicon wafer, i.e. on the n-type amorphous silicon film; on the back side of the silicon wafer, i.e. on the p-type amorp...

Embodiment 3

[0057] refer to figure 1 , Figure 4 , using the radio frequency magnetron sputtering method to deposit a layer of double-layer TCO thin film 201 / 202 with a specific superimposed structure on both sides of the SHJ solar cell. The specific operation method includes the following steps:

[0058] (1) cleaning and texturizing the n-type monocrystalline silicon wafer to obtain a clean silicon wafer substrate with a pyramid structure on the surface;

[0059] (2) Depositing a layer of intrinsic amorphous silicon film passivation layer respectively on the front and back sides of the silicon wafer;

[0060] (3) Continue depositing one deck of n-type doped amorphous silicon film on the front side of the silicon wafer, and continue depositing one deck of p-type doped amorphous silicon film on the back side;

[0061] (4) Deposit a columnar TCO film with a thickness of 20 nm on both sides of the silicon wafer, and then deposit a layer of equiaxed TCO film with a thickness of 80 nm to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Power supply | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com