Production method of battery cover plate provided with explosion-proof structure

A battery cover, explosion-proof structure technology, applied in the direction of battery cover/end cover, structural parts, battery pack components, etc., can solve the problems of complex processing methods, unstable battery performance, easy liquid leakage, etc., to achieve stable explosion-proof performance , good insulation, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to allow those skilled in the art to better understand the technical solution of the present invention, the present invention will be further elaborated below.

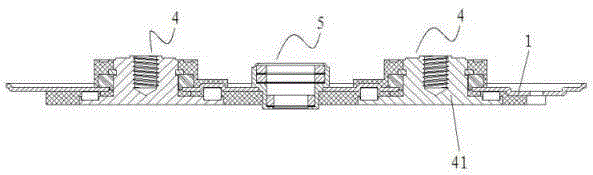

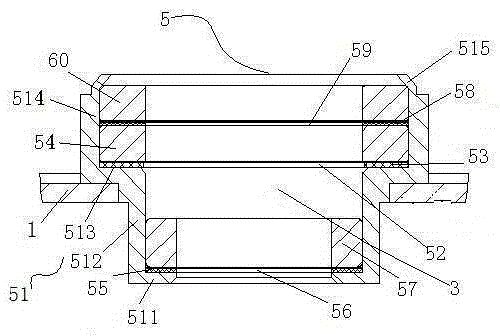

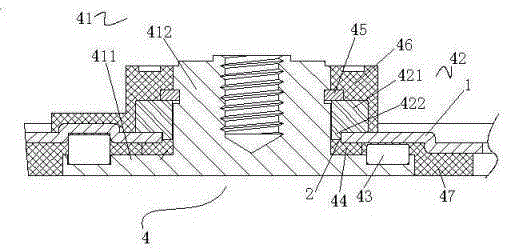

[0030] as attached figure 1 , 2 , 3, a battery cover assembly with an explosion-proof structure, including a cover body 1, two through holes 2 and an exhaust hole 3 are opened on the cover body, and a battery terminal 4 is arranged on the through hole , an explosion-proof structure 5 is provided on the exhaust hole.

[0031] The electrode terminal includes an electrode column 41 passing through the through hole. The electrode column 41 includes a base 411 and a hollow cylinder 412. The hollow cylinder is arranged on the base. The hollow cylinder passes through the through hole of the steel cover plate and is exposed on the steel cover plate. The base is located on Below the through hole of the steel cover plate, the diameter of the base is larger than the diameter of the through hole, and the maximum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com