Liquid crystal aligning agent, liquid crystal aligning film, and liquid crystal display element using the same

A liquid crystal alignment agent, the technology of making tetracarboxylic dianhydride, applied in the directions of instruments, optics, nonlinear optics, etc., can solve problems such as difficulty in meeting, and achieve the effect of maintaining the stability of liquid crystal alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0084] Hereinafter, with regard to the specific details of the production method of the present invention, experimental methods and results thereof, as well as examples of typical production methods, etc., which were studied on the composition of raw materials and compounding ratios, will be described. In addition, this invention is not limited to these Examples.

[0085] Explanation of abbreviations used in this example

[0086] (tetracarboxylic dianhydride)

[0087] Tetracarboxylic dianhydrides of the following CA-1 to CA-7

[0088]

[0089]

[0090] (diamine)

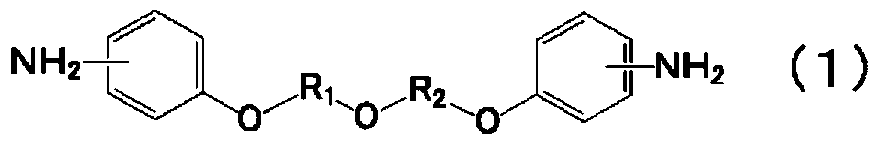

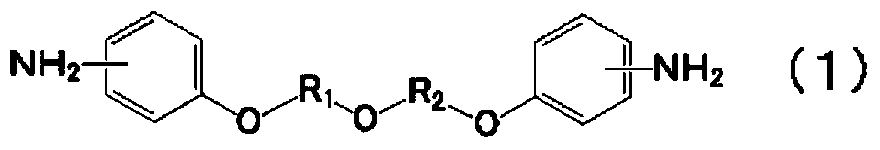

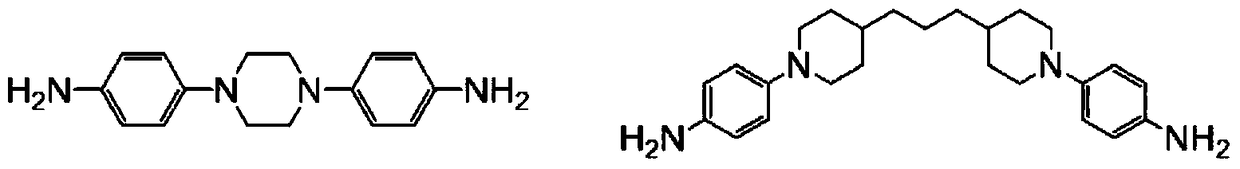

[0091] Diamine compounds of the following DA-1 and DA-2

[0092]

[0093] (Organic solvents)

[0094] NMP: N-methyl-2-pyrrolidone

[0095] BCS: Butyl Cellosolve

[0096] (additive)

[0097] LS-3150: 3-Aminopropyltriethoxysilane

[0098] Each measurement method is shown below.

[0099]

[0100] After filtering the obtained liquid crystal aligning agent with a filter of 1.0 μm, it was spin-coated on...

Synthetic example 1

[0119] Add 7.64g (26.5mmol) of DA-1, 10.4g (26.5mmol) of DA-2, and 100g of N-methyl-2-pyrrolidone to a 200ml four-neck flask equipped with a stirring device and a nitrogen gas introduction tube, and feed nitrogen gas Stir to dissolve. 5.78 g (26.5 mmol) of CA-1 and 3.98 g (15.9 mmol) of CA-3 were added, stirring this diamine solution, and it stirred at 50 degreeC for 3 hours. Thereafter, the temperature of the reaction solution was lowered to 23° C., 1.66 g (8.48 mmol) of CA-2 and N-methyl-2-pyrrolidone were added so that the solid content concentration became 15% by mass, and the mixture was stirred at 23° C. for 20 hours to obtain A solution of polyamic acid (abbreviated as P1). When the viscosity at 25 degreeC of this polyamic-acid (P1) solution was confirmed with the E-type viscometer (made by Toki Sangyo Co., Ltd.), it was 481 mPa*s.

[0120] 87.4 g of N-methyl-2-pyrrolidones, 0.075 g of LS-3150, and 50 g of butyl cellosolves were added to 100 g of this polyamic acid (P...

Synthetic example 2

[0122] Add 7.79g (27.0mmol) of DA-1, 10.6g (27.0mmol) of DA-2 and 100g of N-methyl-2-pyrrolidone to a 200ml four-neck flask equipped with a stirring device and a nitrogen gas inlet tube, and feed nitrogen gas Stir to dissolve. 5.89 g (27.0 mmol) of CA-1 and 3.21 g (16.2 mmol) of CA-4 were added, stirring this diamine solution, and it stirred at 50 degreeC for 3 hours. Thereafter, the temperature of the reaction solution was lowered to 23° C., 1.70 g (8.64 mmol) of CA-2 and N-methyl-2-pyrrolidone were added so that the solid content concentration became 15% by mass, and the mixture was stirred at 23° C. for 20 hours to obtain The solution of polyamic acid (abbreviated as P2). When the viscosity in 25 degreeC of this polyamic-acid (P2) solution was confirmed with the E-type viscometer (made by Toki Sangyo Co., Ltd.), it was 512 mPa*s.

[0123] 87.4 g of N-methyl-2-pyrrolidones, 0.075 g of LS-3150, and 50 g of butyl cellosolves were added to 100 g of this polyamic acid (P2) sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com