Low-temperature cold patch asphalt liquid and preparation method thereof

A cold-patch asphalt and low-temperature technology, which is applied to building insulation materials, building components, buildings, etc., can solve problems such as poor workability, slow strength formation, and insufficient bonding strength of old pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of a kind of low-temperature type cold asphalt liquid provided by the present invention comprises the following steps:

[0033] Step 1, in parts by mass, weigh 100 parts of petroleum pitch, 24-26 parts of light oil, 3-6 parts of tackifier, 3-6 parts of water-based epoxy resin emulsion and 2-3 parts of SBR latex;

[0034] Step 2, heating and dehydrating the weighed petroleum pitch until the heated petroleum pitch is in a molten state, at this time, the heating temperature is 120-130°C;

[0035] Step 3, add light oil to the molten petroleum asphalt in step 2, and stir evenly to obtain diluted asphalt. The duration of the whole process is about 10-15 minutes, and the heating temperature of the asphalt is controlled at 110-120°C;

[0036] Step 4, adding a tackifier to the diluted asphalt in step 3, performing shearing and mixing to obtain an asphalt liquid;

[0037] Step 5: Add water-based epoxy resin emulsion and SBR latex to the asphalt solution ob...

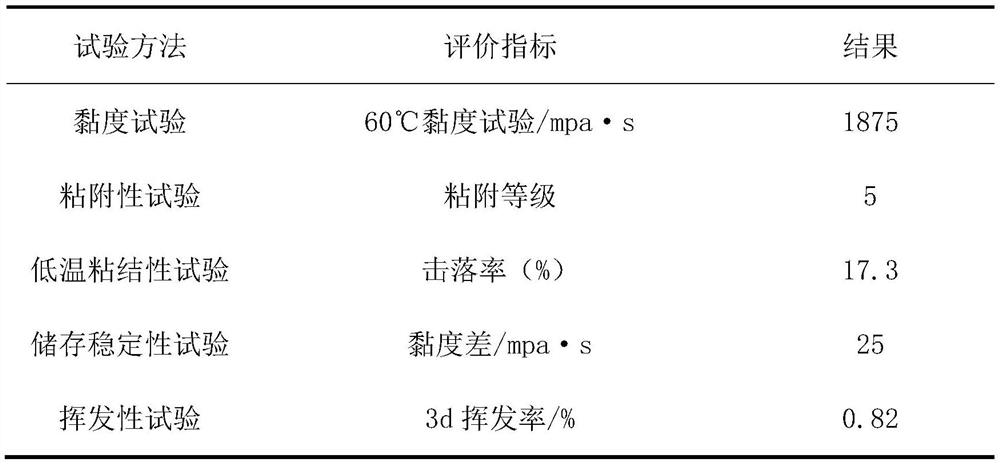

Embodiment 1

[0044] Prepare test instruments and raw materials for the preparation of low-temperature cold replenishment fluid to ensure that the amount of raw materials is sufficient;

[0045] Put a tank containing 100 parts of road petroleum asphalt in an oven to heat and dehydrate until it is in a molten state at 120-130°C;

[0046] Add 24 parts of light oil and stir with a glass rod at the same time to ensure that the diluted bitumen is in a homogeneous state. The duration of the whole process is about 10-15 minutes, and the asphalt heating temperature is controlled at 110-120°C.

[0047] Add 3 parts of tackifier, and cut through high-speed shearing machine for 10-15 minutes to ensure that the additive is fully dissolved in the diluted asphalt. At this time, the temperature of the asphalt liquid should be lowered to below 100°C, and the constant temperature should be kept at 80°C-90°C for use .

[0048] Add 3 parts of water-based epoxy resin emulsion and 2 parts of SBR latex to the a...

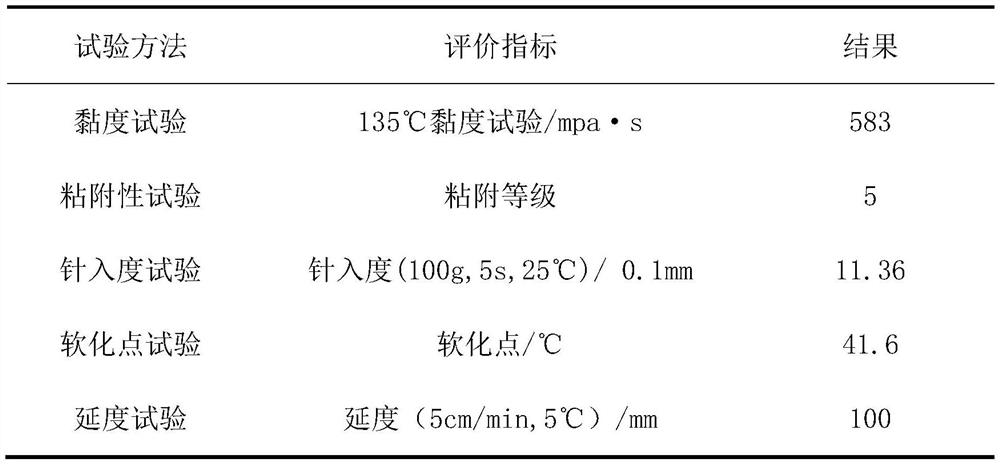

Embodiment 2

[0052] Prepare test instruments and raw materials for the preparation of low-temperature cold replenishment fluid to ensure that the amount of raw materials is sufficient;

[0053] Put a tank containing 100 parts of road petroleum asphalt in an oven to heat and dehydrate until it is in a molten state at 120-130°C;

[0054] Add 26 parts of light oil and stir with a glass rod at the same time to ensure that the diluted bitumen is in a homogeneous state. The duration of the whole process is about 10-15 minutes, and the asphalt heating temperature is controlled at 110-120°C.

[0055]Add 6 parts of tackifier, and cut it through high-speed shearing machine for 10-15 minutes to ensure that the additive is fully dissolved in the diluted asphalt. At this time, the temperature of the asphalt liquid should be lowered to below 100°C, and the constant temperature should be kept at 80°C-90°C for use .

[0056] Add 6 parts of water-based epoxy resin emulsion and 3 parts of SBR latex to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com