Vibration throwing pneumatic type mulch recycling operation method and machine

A working machine and pneumatic technology, which is applied in the field of vibrating throwing pneumatic mulch recovery operation method and working machines, can solve the problems of difficulty in picking up or separating broken mulch, and achieve the effect of reducing workload and improving recovery effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

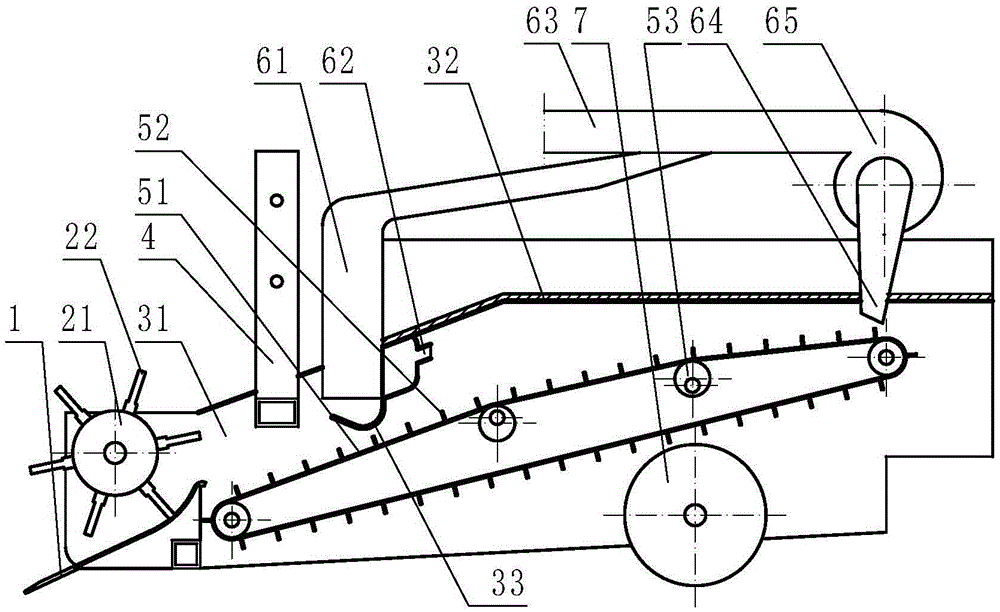

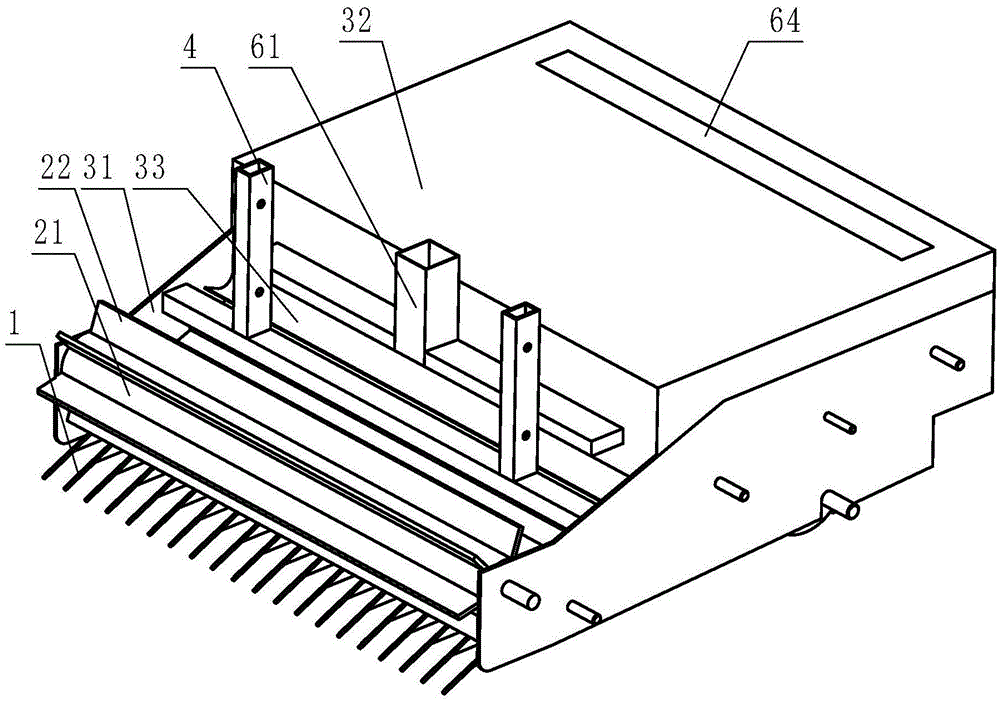

[0034] Embodiment 1: with reference to attached Figure 1-Figure 2, is the structural representation of embodiment 1 of the present invention, comprises main frame 31, traction or suspension frame 4, transmission mechanism, blower fan 65 and soil raising mechanism, blower fan 65 is provided with positive pressure air supply pipe A63, and positive pressure air supply pipe A63 A positive pressure air supply pipe B61 is also provided in parallel, and a vibrating conveying mechanism is provided after the earth-moving mechanism. A cover body 32 is provided, and a positive pressure blowing nozzle 62 and a corresponding negative pressure suction nozzle 64 are arranged in the space formed above the cover body 32 and the conveyor belt 51, and the positive pressure air supply pipe of the positive pressure blowing nozzle 62 and the blower fan 65 B61 is connected, and the blown wind will blow up the mulch fragments floating on the surface, and the negative pressure suction nozzle 64 is co...

Embodiment 2

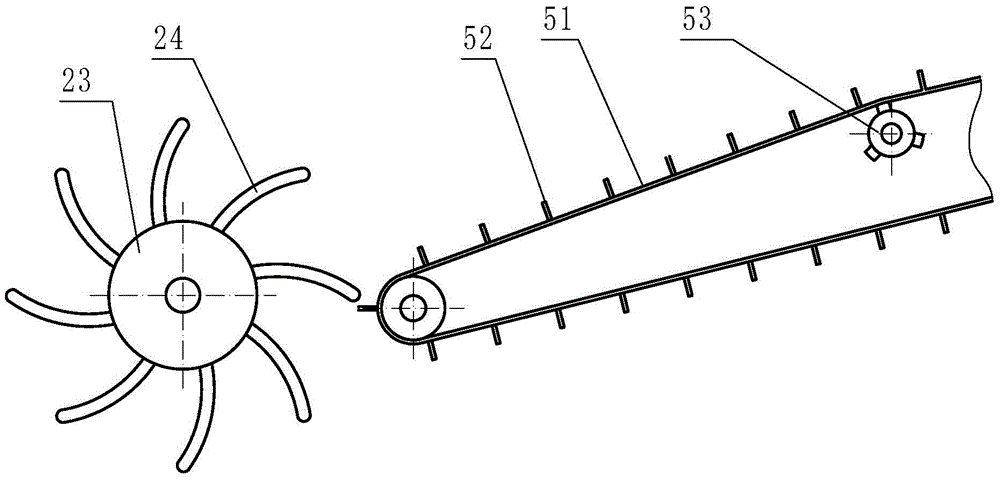

[0036] Embodiment 2: refer to image 3 , Figure 4 , is a structural schematic diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the described soil lifting mechanism is a rotary tillage type: it includes a drum shaft B23, and the surface of the drum shaft B23 is densely covered with upright dials. The soil tooth 24, the front end of the earth-moving tooth 24 is provided with a curved part, and the end of the curved part is in the shape of a flat palm. , The raised rib 52 is an axially elongated protrusion on the drum body.

[0037] Of course, the raised ribs 52 provided on the drum body of the vibrator 53 may also be milky protrusions, or a mixture of elongated protrusions and milky protrusions, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com