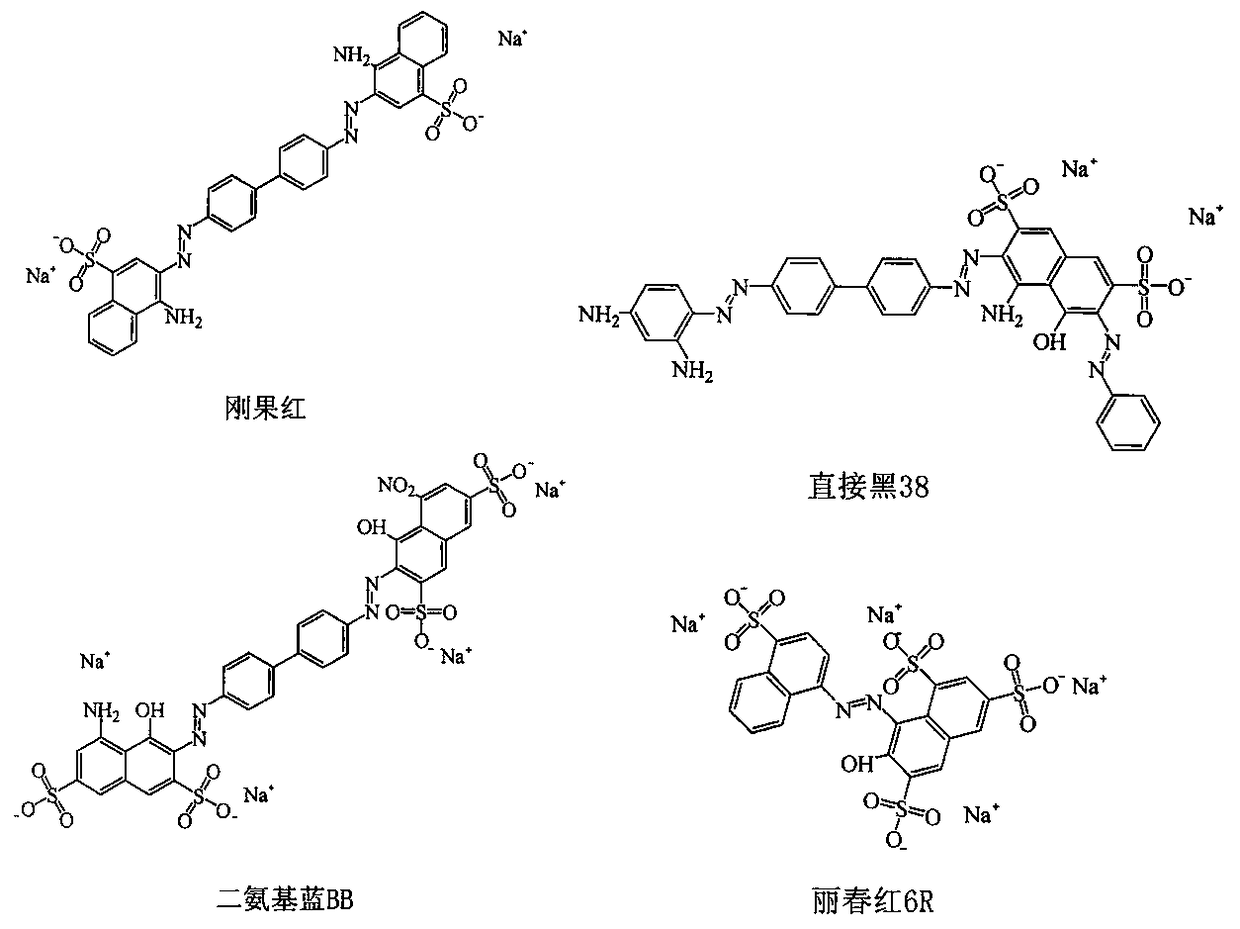

Preparation method of modified silica gel adsorption material for anionic dye wastewater treatment

A technology for anionic dyes and wastewater treatment, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., and can solve problems such as inconvenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

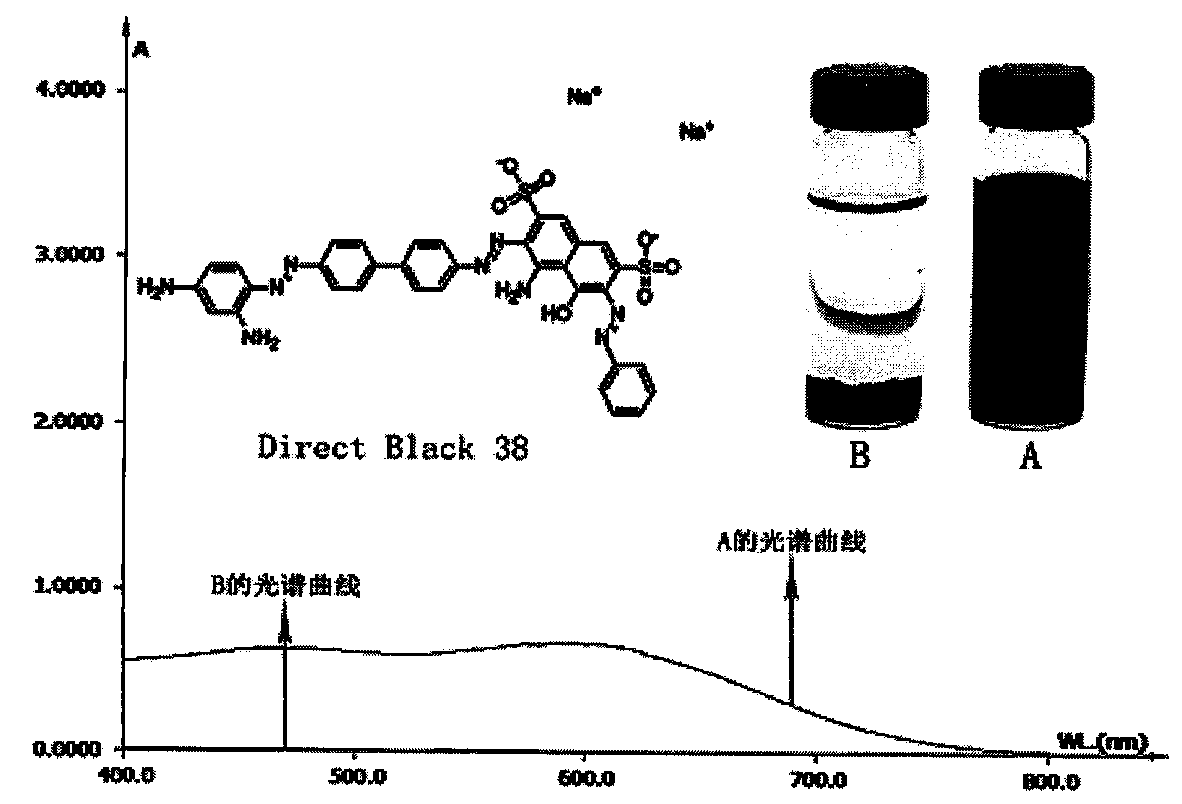

Image

Examples

Embodiment

[0041] a. Add 5g of silica gel into a container filled with 225g-275g of water, mix and stir, let stand for 10-15 minutes, pour out the upper part of the turbid liquid, and dry the precipitated silica gel in an oven at a temperature of 100 ° C for 4 hours for use;

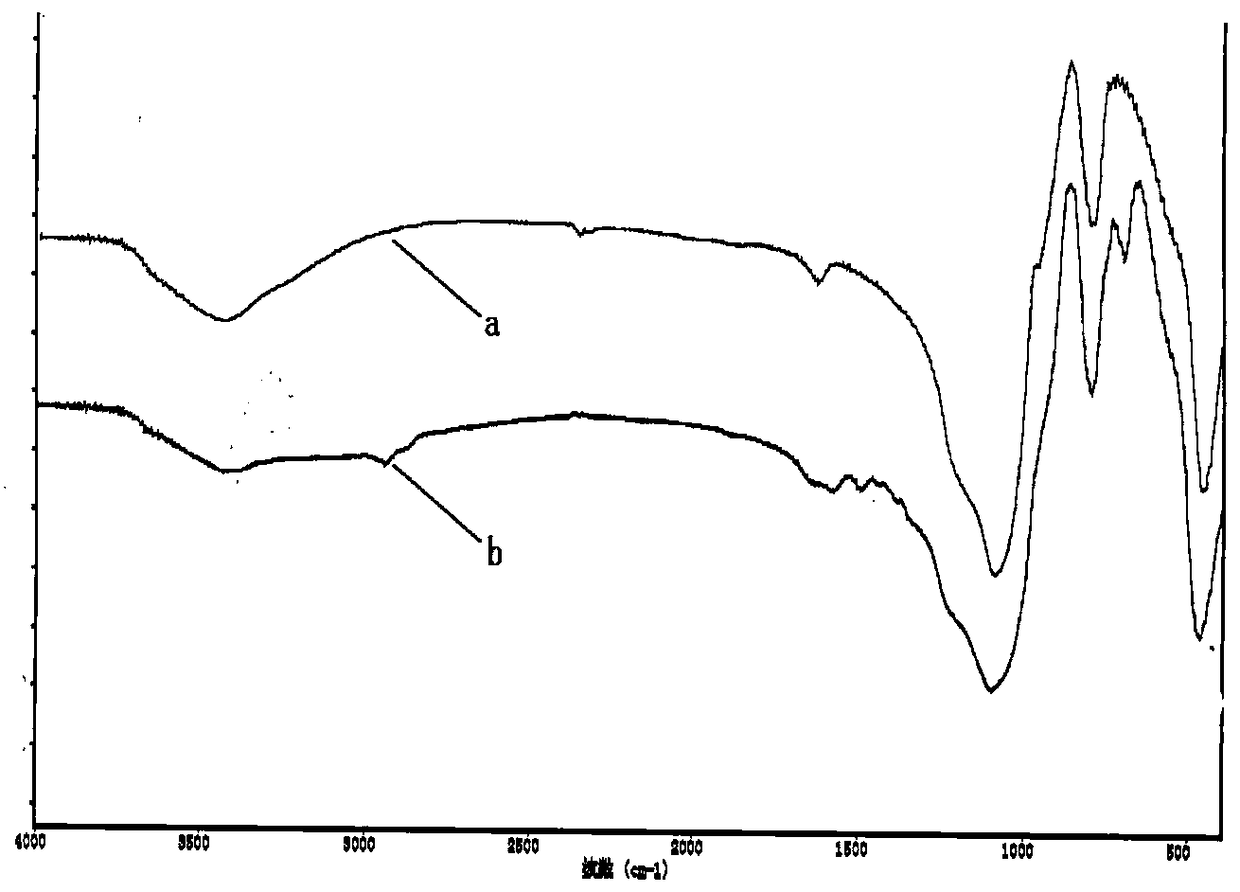

[0042] b. Add 3 g of silica gel treated in step a into the reaction vessel, add toluene as a solvent, stir for 30 minutes, then add deionized water, stir for 30 minutes, and after the silica gel is fully dispersed, add 3-aminopropyltriane Oxysilane was slowly added dropwise to the reactor, stirred at room temperature for 10-14 hours, evaporated under reduced pressure to remove the solvent, and vacuum-dried at a temperature of 70°C-90°C for 4-8 hours to obtain 3-aminopropyl triacetate in white powder form. Alkoxysilane modified silica gel;

[0043] c. Add the white powdery 3-aminopropyltrialkoxysilane-modified silica gel obtained in step b into an aqueous solution of hydrochloric acid, nitric acid or sulfuric acid w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com