High-accuracy surface fine machining and finish machining method for thin-wall wheel discs

A fine processing and finishing technology, applied in the field of aero-engines, can solve the problems of poor edge size consistency, unstable quality, and difficult to guarantee roughness, and achieve uniform and regular surface texture, low surface roughness value, and surface topography. The effect of improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

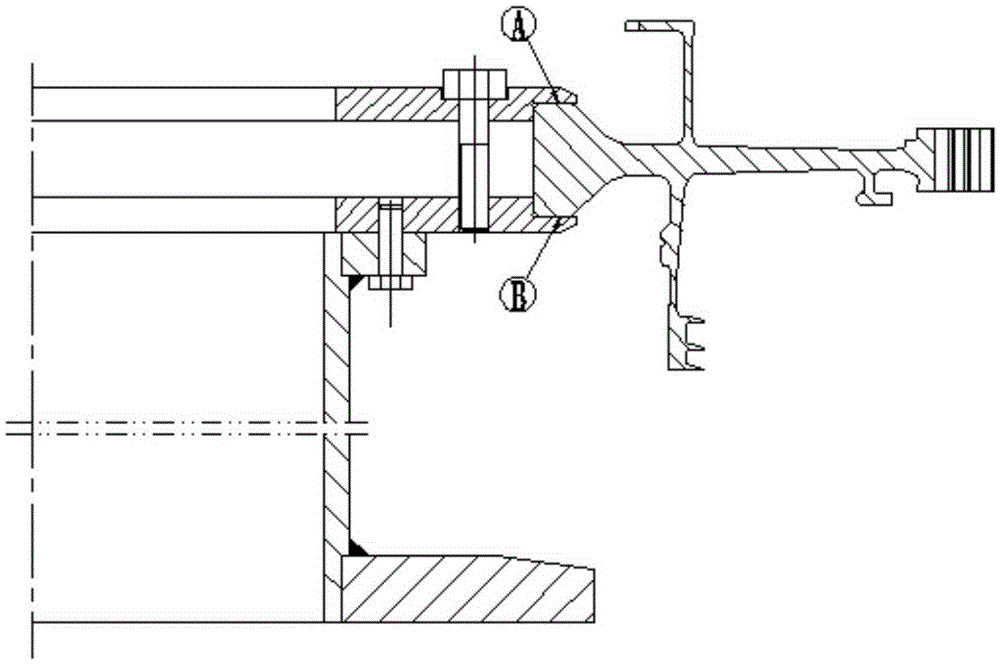

[0037] 1. Part structure

[0038] Such as figure 1 As shown, the turbine disk part is a thin-walled disk with a large diameter and complex structure, with a mounting edge structure. The mounting edge and the disc web form a semi-closed deep cavity, and the opening is extremely poor. Among them, the surface roughness of the rim, web, outer circle at the installation edge, end face and deep cavity of the web is strictly required, all of which are Ra0.80μm. In the past, manual polishing has been used for processing. Due to the poor openness of the turbine disc cavity, manual polishing is required. Polishing is almost unreachable, the roughness is not easy to guarantee, and the quality is unstable.

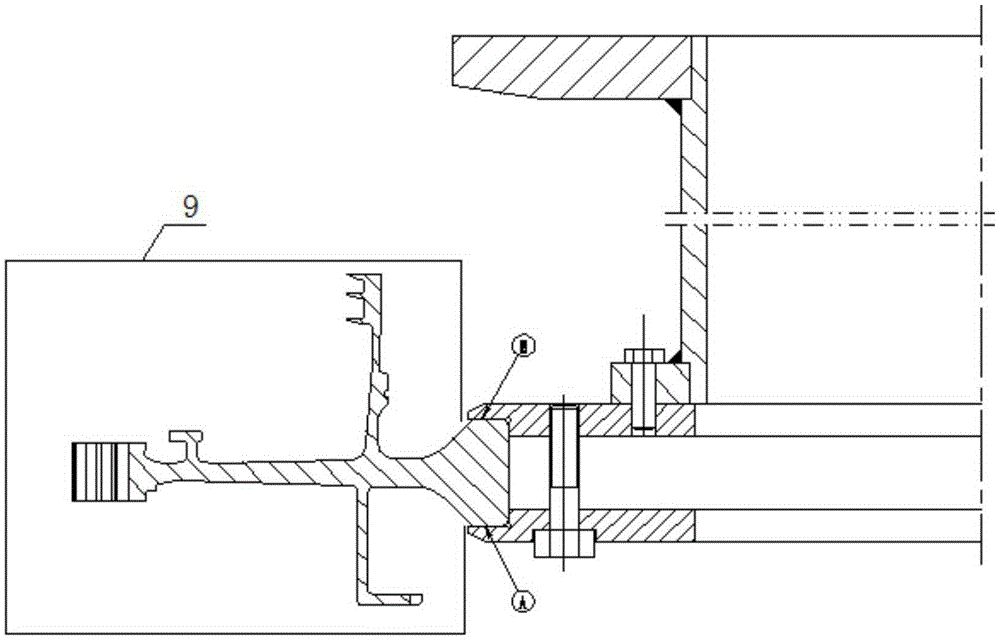

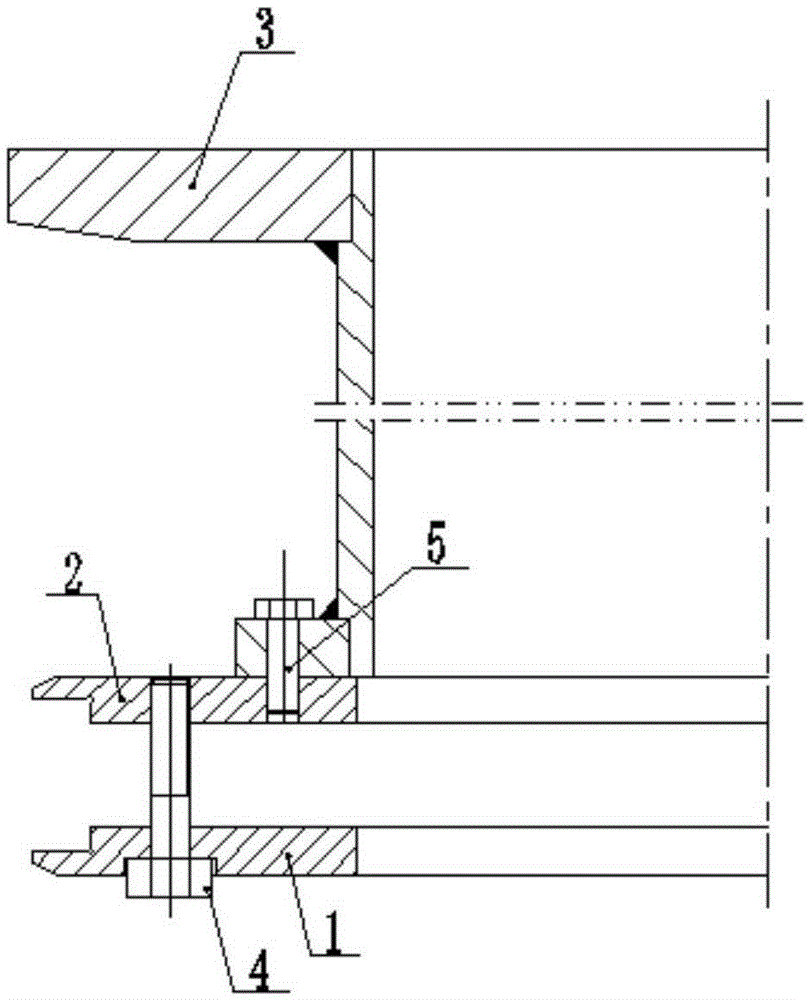

[0039] 2. Fixture structure

[0040] A set of special fixtures are used for the vibration and finishing process of the turbine disk. The special fixture i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com