A high-efficiency environment-friendly automobile muffler and its noise reduction method

A car muffler, environmental protection technology, applied in the direction of muffler, machine/engine, engine components, etc., can solve the lack of muffler and other problems, achieve high sound absorption coefficient, overcome moisture absorption, strong noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

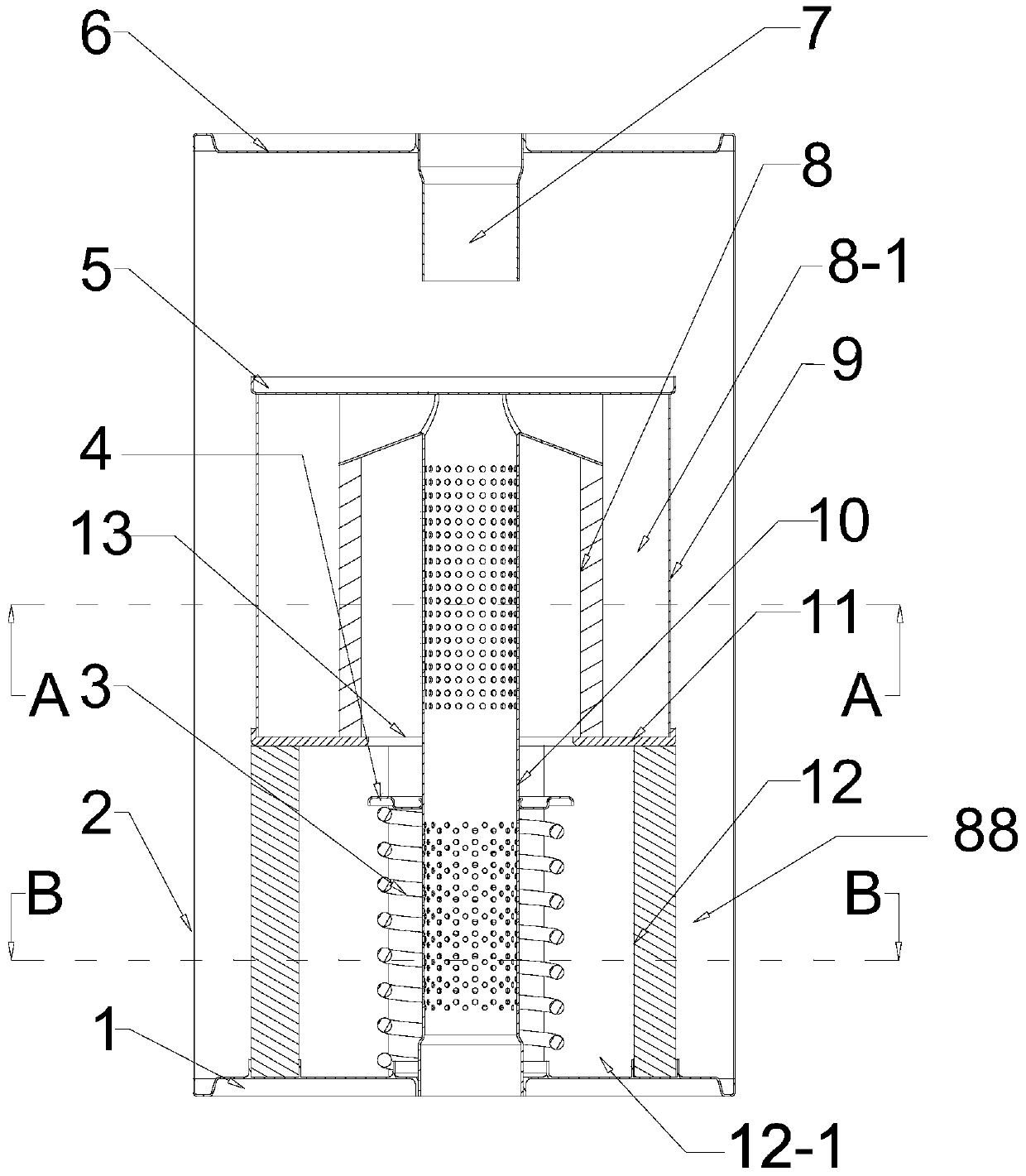

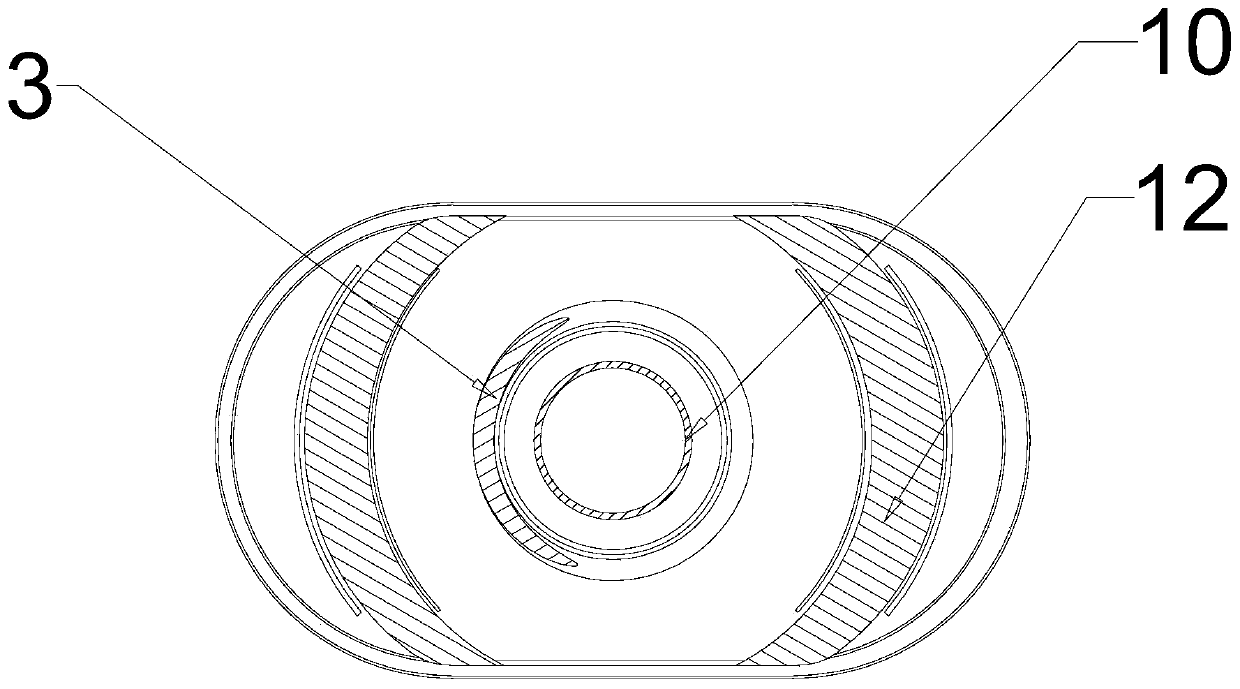

[0029] Such as Figures 1 to 3 shown. The invention discloses a high-efficiency environment-friendly automobile muffler, which comprises an outer cylinder body 2 and a sound-absorbing cavity arranged in the outer cylinder body 2. A perforated air intake pipe 10 with air hole arrays distributed at both ends is arranged in the sound-absorbing cavity. The middle part of the perforated air intake pipe 10 is provided with an air intake chamber partition 11;

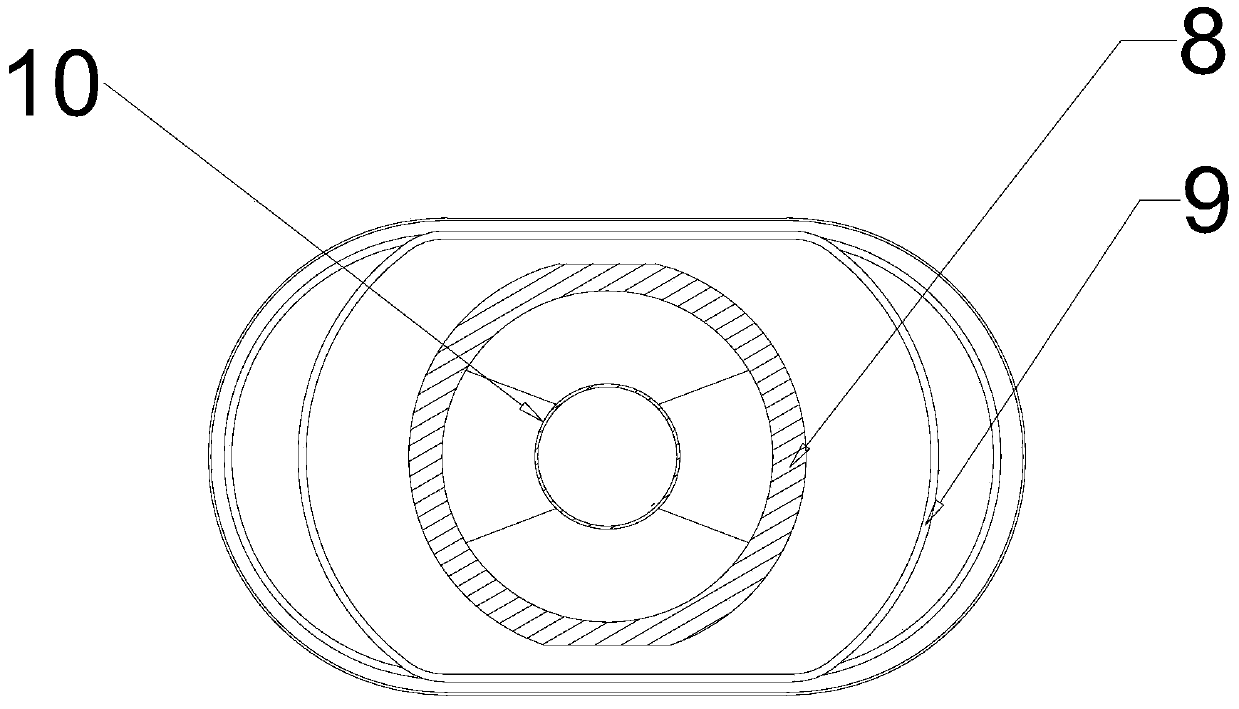

[0030] Bounded by the partition plate 11 of the air intake cavity, the sound absorption cavity is divided into an air intake cavity 12-1 surrounded by the first-stage foam aluminum sound-absorbing board 12 and an intermediate chamber 8-1 surrounded by the second-stage foam aluminum sound-absorbing board 8- 1. The outer casing of the secondary foam aluminum sound-absorbing board 8 is provided with an outer cylinder 9 in the middle cavity;

[0031] The outer edge of the mouth of the perforated air intake pipe 10 is snap-connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com