Preparation method for photonic crystal plastic scintillator

A plastic scintillator and photonic crystal technology, which is applied in the field of nuclear radiation measurement, can solve the problems of easily damaged plastic scintillator, complexity, scintillator tearing, etc., and achieve the effects of avoiding luminous interference, simplifying the preparation process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

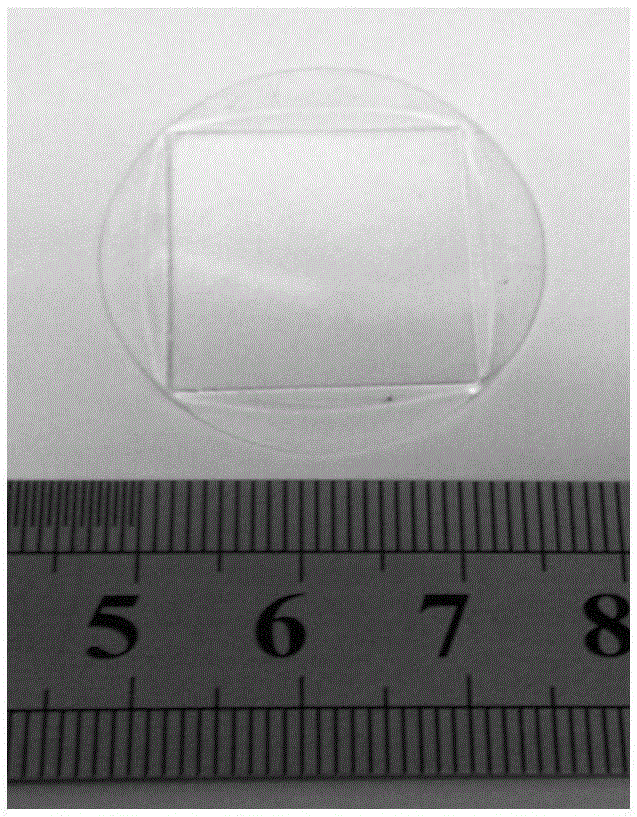

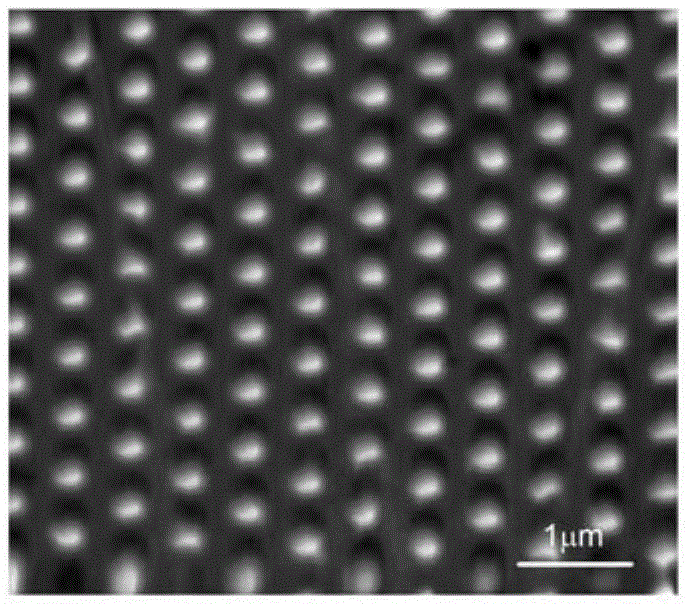

[0025] Photonic crystals were prepared on the surface of the plastic scintillator model NE102. The selected template structure was a columnar periodic array with a triangular structure, the period was 600nm, the diameter of the columns was 300nm, the height was 300nm, and the template area was 20×20mm 2 , the template material is quartz, and the structure of the obtained photonic crystal is the complementary structure of the template pattern, that is, a periodic array of holes in a triangular structure. The period is 600nm, the diameter of the holes is 300nm, and the height is 300nm. 20mm 2 .

[0026] The preparation process is as follows: Step 1: purchase NE102 plastic scintillator, cut and polish to obtain a scintillator with a flat surface, and its size is 3 cm in diameter and 0.5 mm in thickness. Purchase a template piece of the above structure. Step 2: Perform anti-sticking treatment on the template, put the template in a nitrogen-protected flask, and slowly pour in per...

Embodiment 2

[0028] Photonic crystals were prepared on the surface of EJ212 plastic scintillator. The selected template structure was a square columnar periodic array with a period of 500nm, a column diameter of 250nm, a height of 300nm, and a template area of 8.5×8.5mm. 2 , the template material is silicon, and the structure of the obtained photonic crystal is the complementary structure of the template pattern, that is, a periodic array of holes with a square structure, the period is 500nm, the diameter of the holes is 250nm, and the height is 300nm. The total area obtained is 8.5× 8.5mm 2 .

[0029] The preparation process is as follows: Step 1: EJ212 plastic scintillator was purchased, cut and polished to obtain a scintillator with a flat surface, and its size was 2 cm in diameter and 1 mm in thickness. Purchase a template piece of the above structure. Step 2: Anti-adhesive treatment of the template, put the template in a nitrogen-protected flask, and slowly pour in perfluoroquinyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com