Machining scheduling method for porcelain calcination process based on ant colony optimization

A technology of calcination process and scheduling method, which is applied in the field of ceramic calcination, and can solve problems such as increased production costs, environmental pollution, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In this embodiment, a processing scheduling method based on ant colony optimization for porcelain calcination process is aimed at the calcination link in the mass production process of porcelain, and adopts the encoding and decoding mechanism and optimization strategy of ant colony algorithm to obtain batch production of porcelain production program, so as to greatly improve production efficiency and reduce production costs, and at the same time give a program development program under the JSP environment, so that when faced with different practical problems, the algorithm can be efficiently implemented to obtain a production program; specifically, it is Proceed as follows:

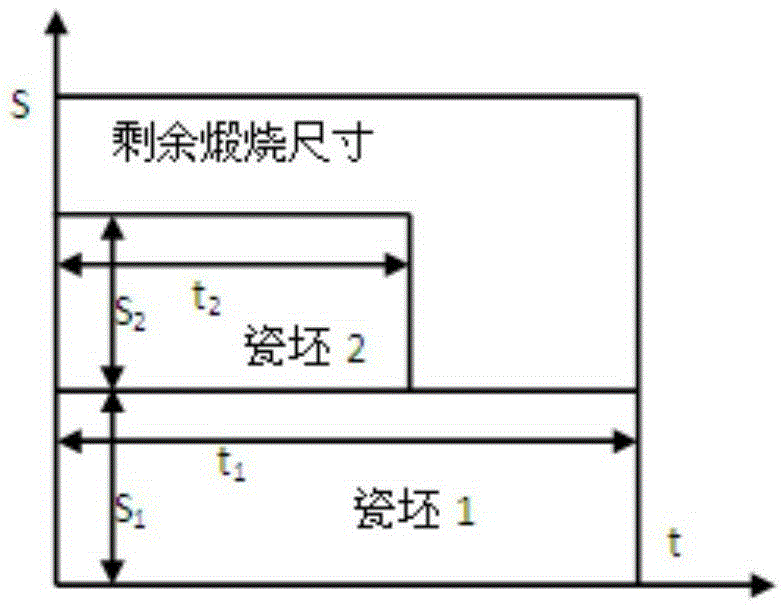

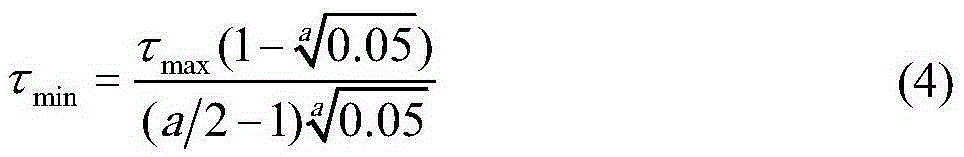

[0053] Step 1. Record all the porcelain blanks in the porcelain calcination process as a set H={h 1 , h 2 ,...,h y ,...,h n}; h y Indicates the y-th ceramic body; then the size of the i-th porcelain body is recorded as s i ; The processing time of the yth porcelain blank is recorded as t y ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com