Netty anti-explosion gradual-change sheet resistance metalized safety film for capacitor

A technology of gradient square resistance and metallized film, which is applied in the field of capacitors, can solve the problems of flammable and explosive capacitors, short service life, poor reliability, etc., and achieve the effect of solving flammable and explosive, high explosion-proof safety performance and sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

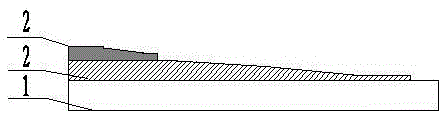

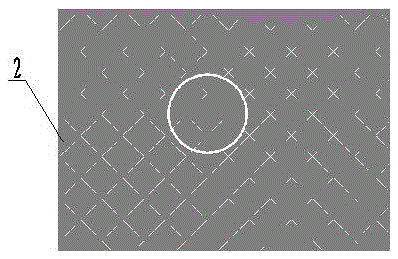

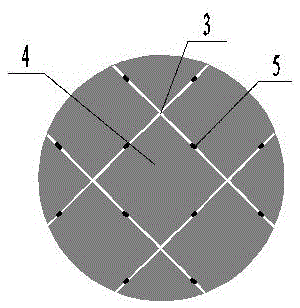

[0011] see Figure 1-3 , the present invention comprises a polypropylene film medium layer 1 and a metallized film layer 2 deposited on the polypropylene film medium layer by uniformly mixed zinc-aluminum vapor deposition, the metallized film layer 2 is two layers, and the metallized film layer 2 forms a network shape structure and is divided into conductive metal grids 4 by X-shaped non-plating area 3, and the micro-fuse 5 formed by the vapor-deposited metallized film layer between adjacent X-shaped non-plating areas 3 is disconnected, and the conductive metal mesh Grids 4 are connected by miniature fuses 5 .

[0012] Miniature fuse 5 is the key structure of explosion-proof among the present invention, as image 3 As shown, after the voltage is applied to both ends of the capacitor made of mesh explosion-proof gradient square resistance metallized safety film of the present invention, when the voltage at both ends of the capacitor electrode increases, the current flowing thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com