Illite mesoporous composite material, supported catalyst and preparation method and application thereof and preparation method of cyclohexanone glyceryl ketal

The technology of a composite material and illite is applied in the field of a spherical illite mesoporous composite material, which can solve the problems of low conversion rate of reaction raw materials, and achieve the effects of less side reactions, high catalytic activity and simple post-processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

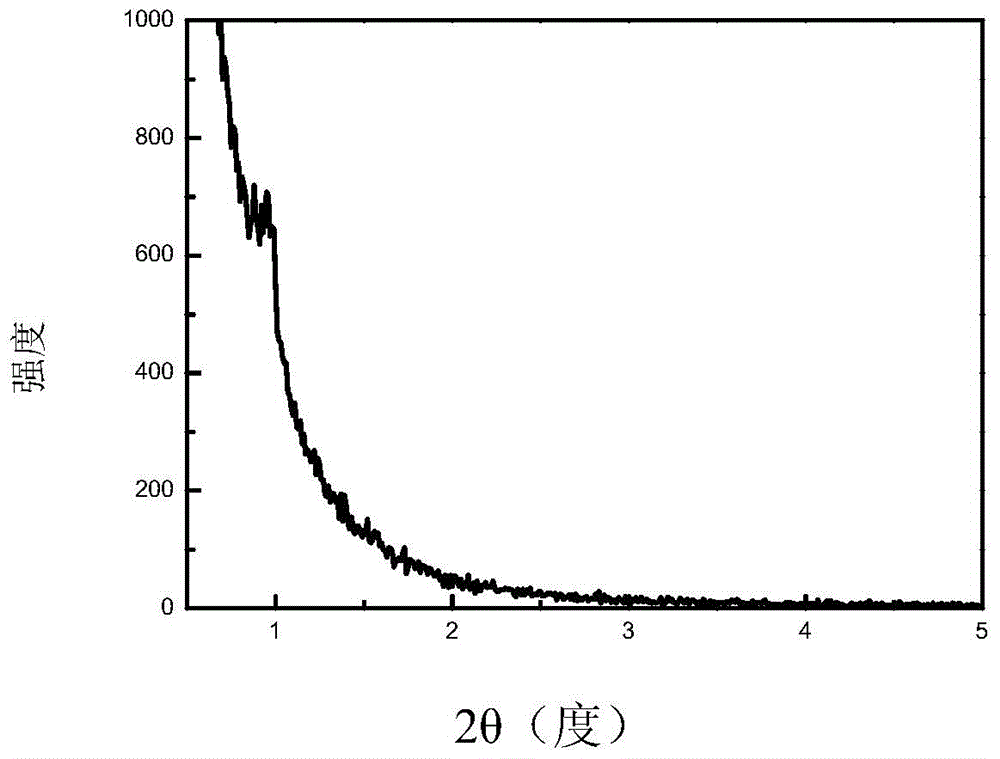

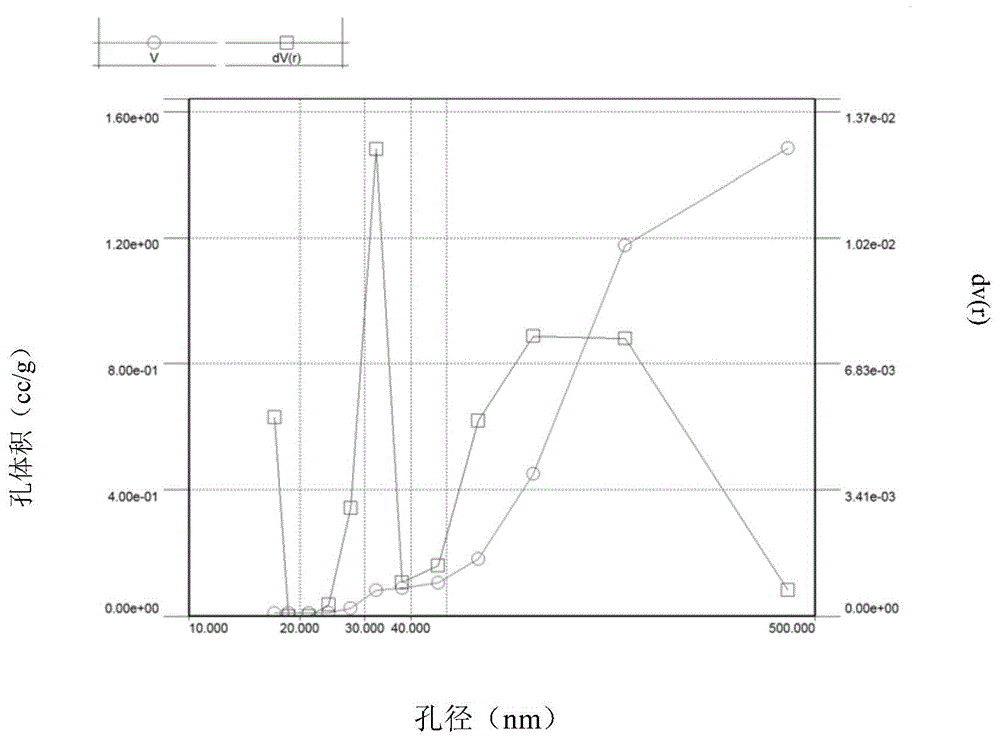

[0049] In step (1), "providing a mesoporous molecular sieve material with a one-dimensional hexagonal pore distribution structure" can be directly weighing or selecting a product of a mesoporous molecular sieve material with a one-dimensional hexagonal pore distribution structure, or preparing a product with a one-dimensional hexagonal pore distribution structure. Mesoporous molecular sieve materials with hexagonal channel distribution structure. The preparation method of the mesoporous molecular sieve material with a one-dimensional hexagonal pore distribution structure can be implemented according to conventional methods, for example, the preparation method can include: preparing the filter material of the mesoporous molecular sieve material with a one-dimensional hexagonal pore distribution structure according to the above method Cake, then the resulting filter cake is dried, and the templating agent in the product obtained after drying is removed. The conditions for removi...

Embodiment 1

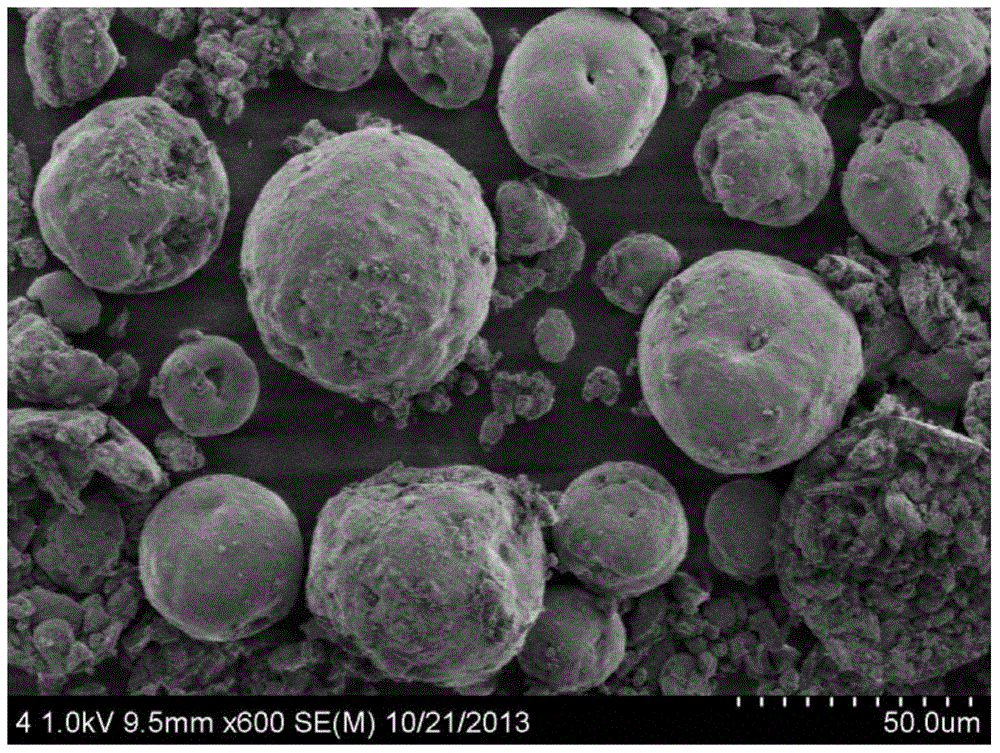

[0093] This example is used to illustrate the spherical illite mesoporous composite material and supported catalyst of the present invention and their preparation methods.

[0094] (1) Preparation of spherical illite mesoporous composites

[0095] Add 1.0g (0.0002mol) of triblock copolymer surfactant P123 and 2.76g (0.06mol) of ethanol to 28ml of acetic acid and sodium acetate buffer with a pH value of 4, and stir at 15°C until P123 is completely dissolved , then add 6g (0.053mol) trimethylpentane to the resulting solution, stir at 15°C for 8h, then add 2.13g (0.014mol) tetramethoxysilane, at 15°C, pH value is 4.5 Stirring for 20h under the conditions, then the obtained solution was transferred to a polytetrafluoroethylene-lined reactor, crystallized at 60°C for 24h, then filtered and washed 4 times with deionized water, and then suction filtered to obtain a Filter cake A1 of mesoporous molecular sieve material with single-dimensional hexagonal channel distribution structure;...

Embodiment 2

[0113] This example is used to illustrate the spherical illite mesoporous composite material and supported catalyst of the present invention and their preparation methods.

[0114] The spherical illite mesoporous composite material and the supported catalyst were prepared according to the method of Example 1. The difference was that there was no spray-drying step in the process of preparing the supported catalyst, but only the benzenesulfonic acid was loaded on the spherical illite by the method of impregnation. On the illite mesoporous composite material, the supported catalyst Cat-2 was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com