Preparation method for high-purity lignin

A lignin and high-purity technology, applied in the field of biomass resource conversion and utilization, can solve the problems of resource waste, environmental pollution, and limit the high-value utilization of lignin, and achieve the effect of reducing molecular weight distribution and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, the preparation of high-purity lignin

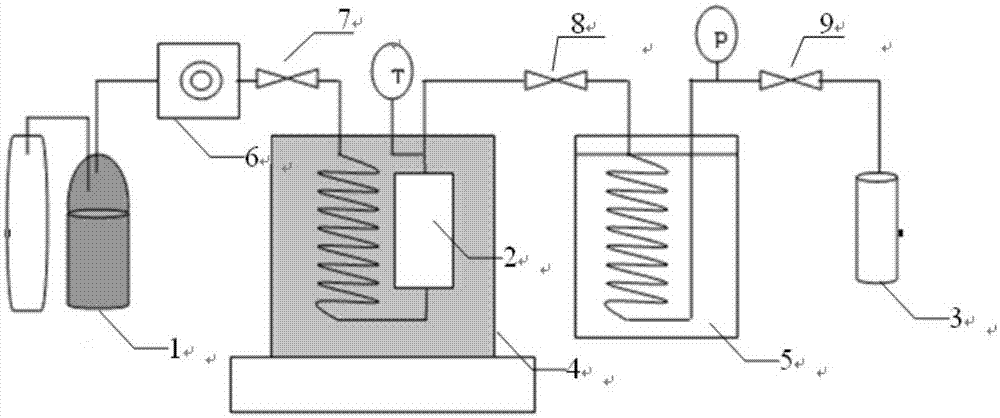

[0038] use as figure 1 The device shown is prepared, and the specific process is as follows: put 5 g of the lignin raw material that has been dried and pulverized into a 40-60 mesh alkali-extracted lignin into the reactor 2, and the neutral desiccant with a pH of 7.0 is prepared in the container 1 where the electrogenerated functional water is placed. Ionized water, adjust the flow rate to be 25mL / min, inject the reactor 2 through the high-pressure pump 6, the pressure of the reaction tube in the reactor 2 is 2MPa, then immerse the reaction tube into the sand bath 4 with a temperature of 180°C, when the reaction tube Start timing when the outlet temperature reaches 180°C. After 10 minutes of reaction, quickly take out the reaction tube and move it to a container filled with cold water to rapidly cool down to terminate the reaction. The reaction tube is taken out and placed in the water bath 5 for cooling. During th...

Embodiment 2

[0040] Embodiment 2, the preparation of high-purity lignin

[0041] use as figure 1 The device shown is prepared, and the specific process is as follows: put 5 g of corn stalk raw material that has been dried and pulverized into 40-60 meshes into the reaction tube of reactor 2, and the acidic aqueous solution with a pH of 2.17 is prepared in container 1 where electrogenerated functional water is placed, Adjust the flow rate to 25mL / min, inject it into the reactor 2 through the high-pressure pump 6, the pressure in the reaction tube is 2.5MPa, then immerse the reaction tube in the sand bath 4 with a temperature of 240°C, when the outlet temperature of the reaction tube reaches 240°C After 6 minutes of reaction, the reaction tube was quickly taken out, and moved to a container equipped with cold water to rapidly cool down to terminate the reaction. The reaction tube is taken out and placed in the water bath 5 for cooling. During the reaction, the effluent solution (i.e. the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com