Electrode type molten salt heater

A heater and electrode type technology, which is applied in the field of electrode type molten salt heaters, can solve the problems of large area occupied by molten salt electric heaters, small voltage levels of resistance type molten salt heaters, and high construction investment costs, achieving safety The effect of excellent performance, compact structure and low basic investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

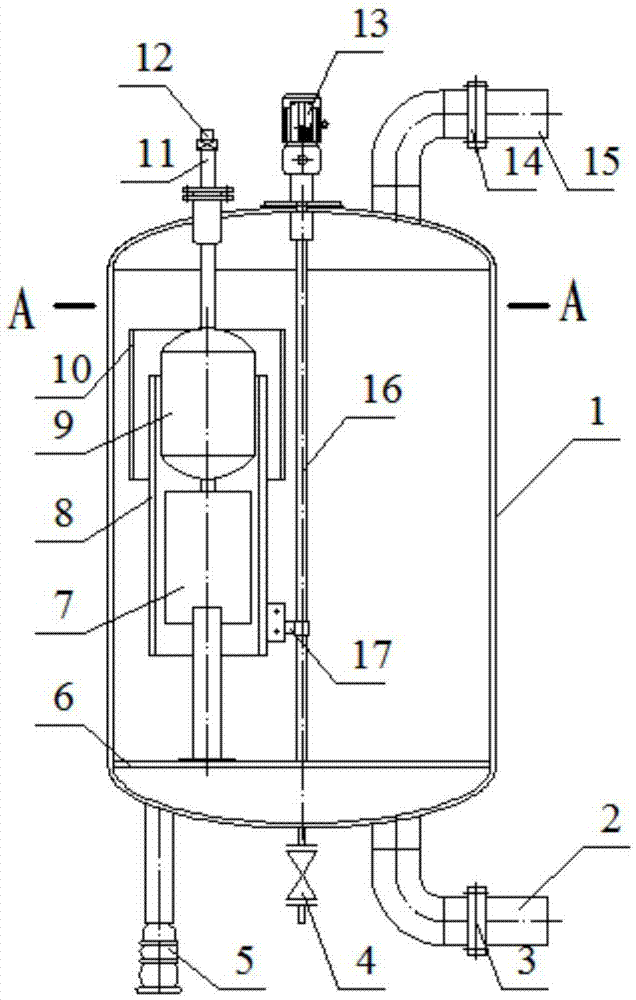

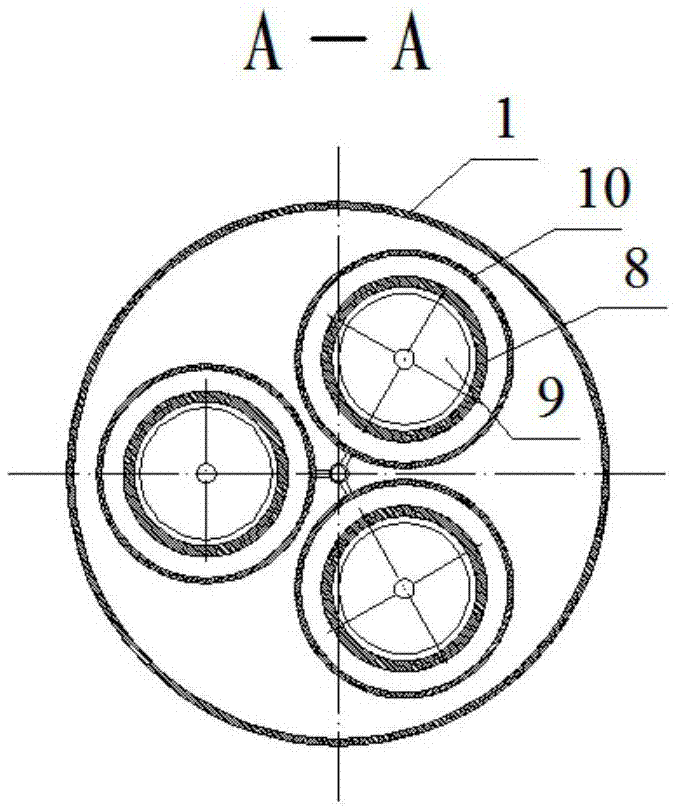

[0022] Embodiment: An electrode-type molten salt heater, including a cylinder body 1, a molten salt inlet 2, an insulating flange A3, a salt discharge valve 4, an insulating support 5, a support plate 6, an electrode bracket 7, a control shield 8, three Phase electrode 9, neutral electrode 10, insulator 11, power interface 12, motor 13, insulating flange B14, molten salt outlet 15, screw rod 16 and movable connector 17.

[0023] The cylinder body 1 is a cylinder in the middle, and semi-elliptical heads are seamlessly welded at both ends; the support plate 6 is located on the opening of the lower semi-elliptical head.

[0024] A motor 13 , a molten salt outlet 15 , and a power interface 12 are respectively provided at the middle, right and left sides of the top of the cylinder 1 ; an insulator 11 is provided between the power interface 12 and the cylinder 1 .

[0025] The middle, right and left sides of the bottom of the cylinder body 1 are respectively provided with a salt dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com