Display device

A display device and display surface technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of high temperature, uneven color, and uneven brightness of light-emitting diodes, and achieve uniform brightness, reduce production costs, and improve recovery rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

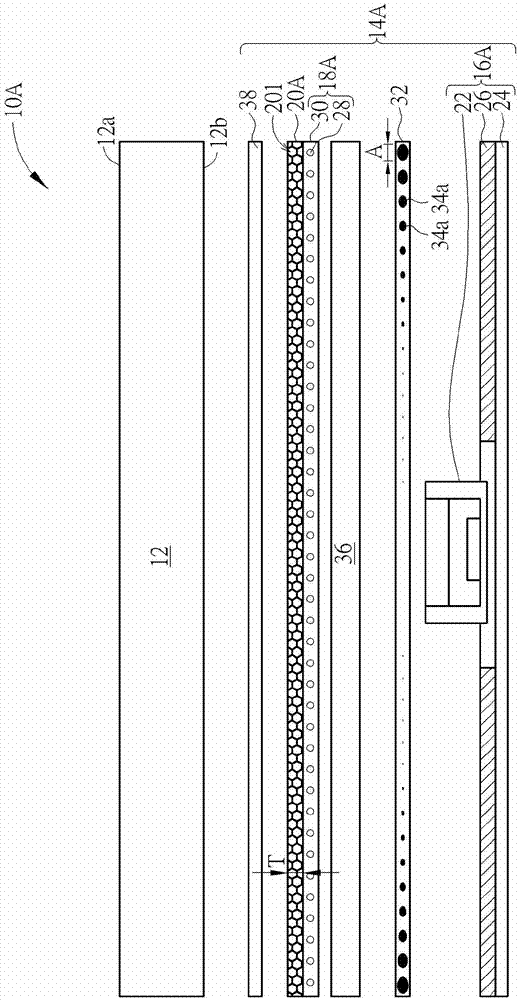

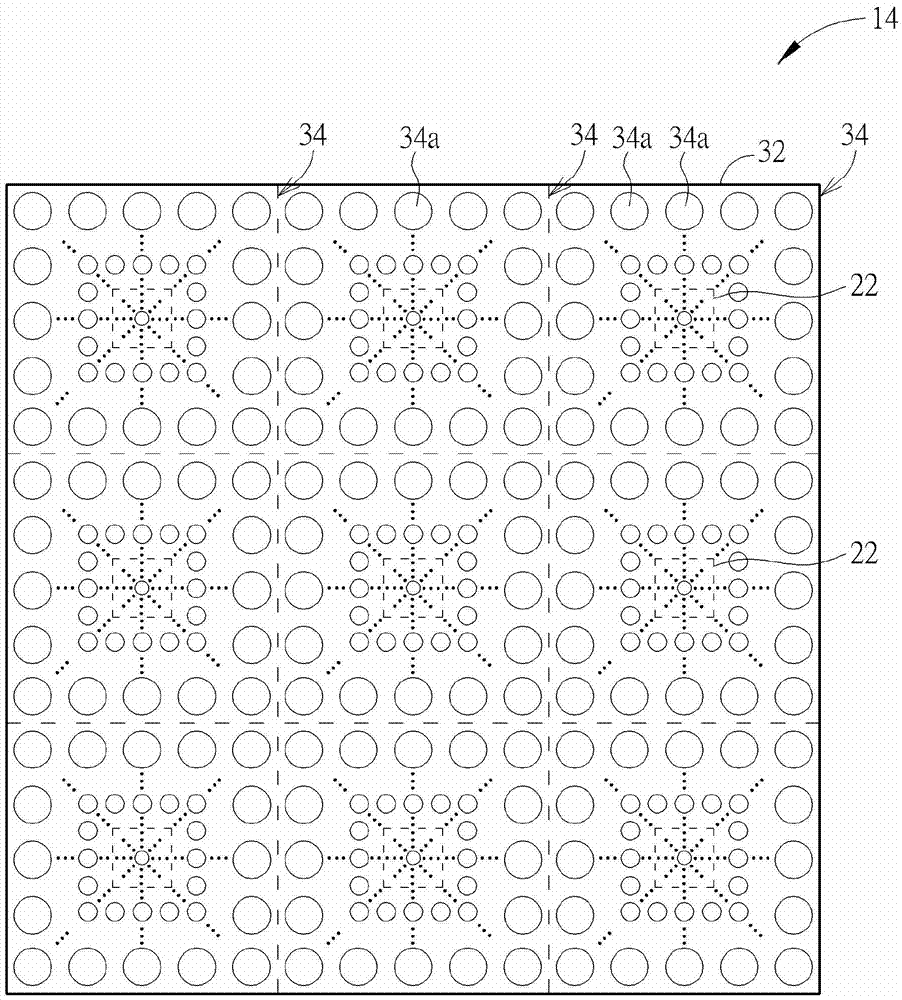

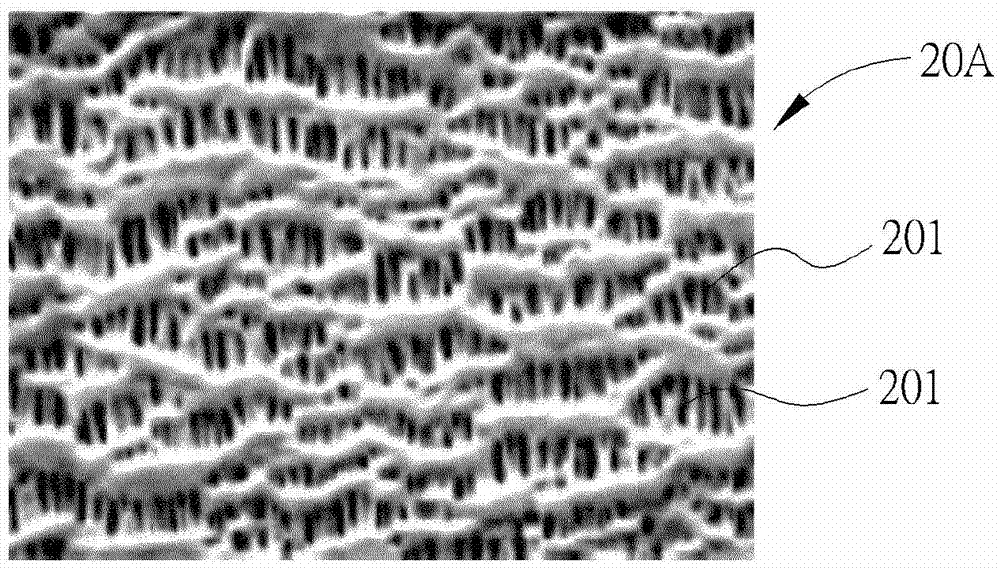

[0085] Please refer to Figure 10 and Figure 11 , Figure 10 shows a schematic cross-sectional view of a display device according to a fourth embodiment of the present invention, Figure 11 A schematic diagram of a porous layer according to a fourth embodiment of the present invention is shown, Figure 11A An enlarged schematic view of the pores in the porous layer according to the fourth embodiment of the present invention is shown. like Figure 10 , Figure 11 and Figure 11A As shown, this embodiment provides another display device 10C. Compared with the first embodiment, the porous layer 20B of the backlight module 14C of this embodiment further includes a plurality of microparticles 42A and a plurality of second quantum dot phosphors 44, the microparticles 42A are arranged in the pores 201, and the second quantum dots Phosphor powder 44 is arranged and distributed in the microparticles 42A. Microparticles 42A can include PMMA, MS, PC, PET, PP, PE, oxides or a mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com