Parallel magnetic circuit multi-adhesion surface high-speed electromagnet

A technology of high-speed electromagnet and suction surface, applied in the field of electromagnet, can solve the problems of electromagnet safety reliability and life reduction, speed up the release speed of armature, and long current action time, etc., achieve uniform distribution of magnetic induction intensity, and accelerate suction Speed, the effect of accelerating the release speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

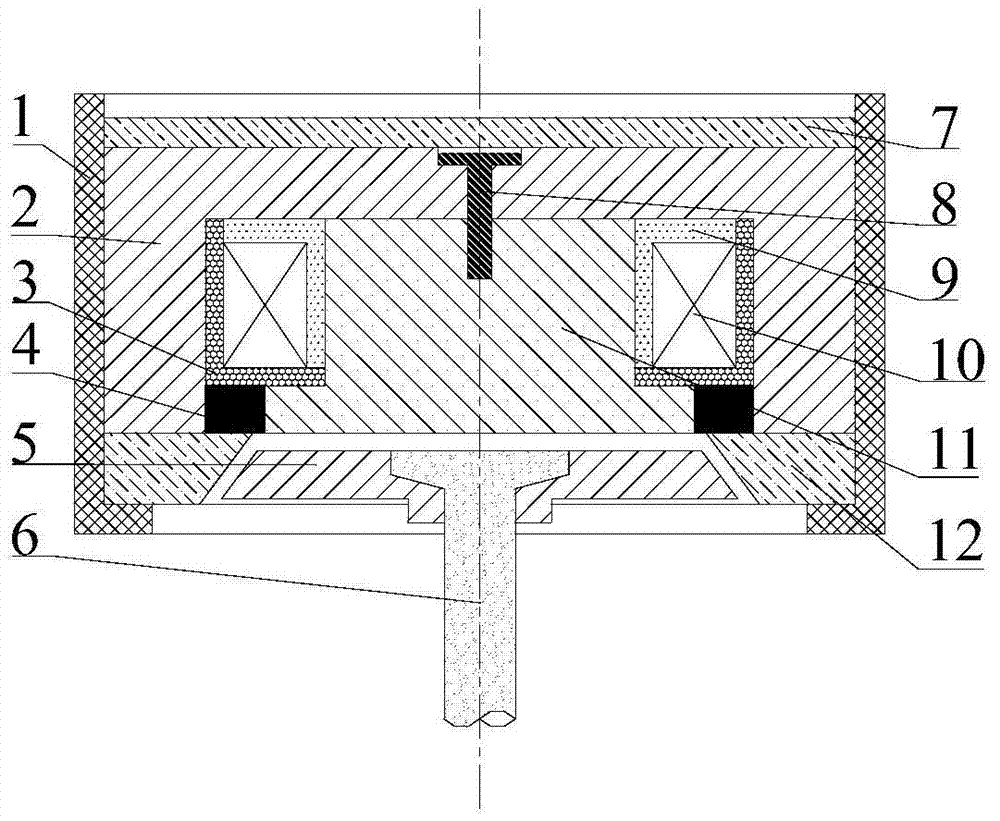

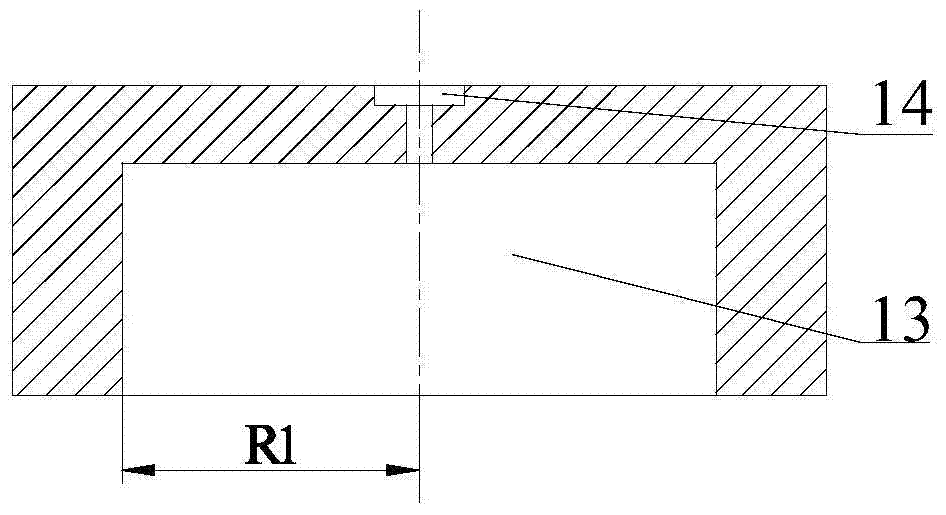

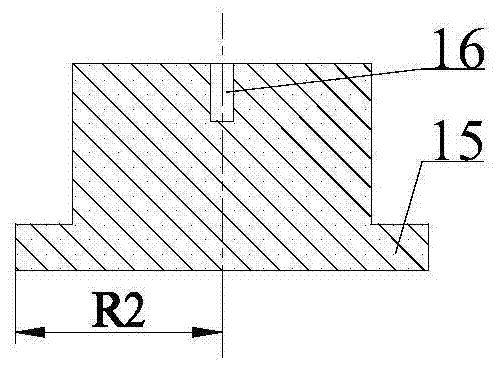

[0022] combine figure 1 , figure 2 , image 3 , Figure 4(a), Figure 4(b), Figure 4(c), Figure 5 and Image 6 , the composition of the parallel magnetic circuit multi-adhesion high-speed electromagnet of the present invention includes a housing 1, an outer iron core 2, a sealing resin 3, a permanent magnet 4, an armature 5, a valve stem 6, a fastening nut 7, a screw 8, and a coil Skeleton 9 , coil 10 , inner core 11 and yoke 12 . The housing 1 is a cylinder with a stepped through hole in the center, and the upper end is tapped with threads. The outer iron core 2 is cylindrical, with a cylindrical hole 13 in the center and a countersunk hole 14 in the center of the top. The inner iron core 11 is a cylinder with a flange 15 at the bottom, and its height is equal to the depth of the cylindrical hole in the center of the outer iron core. At the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com