Method for preparing gate dielectric on silicon carbide material

A gate dielectric, silicon carbide technology, applied in semiconductor/solid-state device manufacturing, electrical components, transistors, etc., can solve the problem of low effective mobility of silicon carbide MOSFET devices, high interface state density of silicon carbide MOS, and low interface defect state density, etc. problem, to achieve the effect of increasing the carrier concentration, reducing the interface state density, and reducing the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

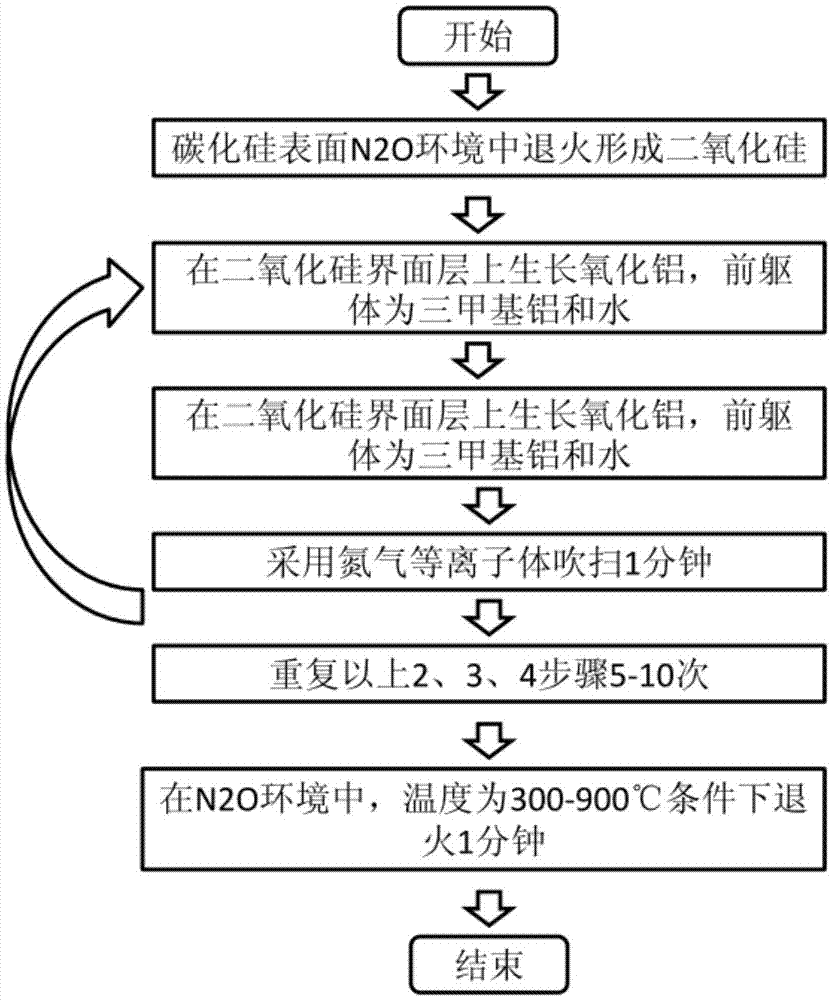

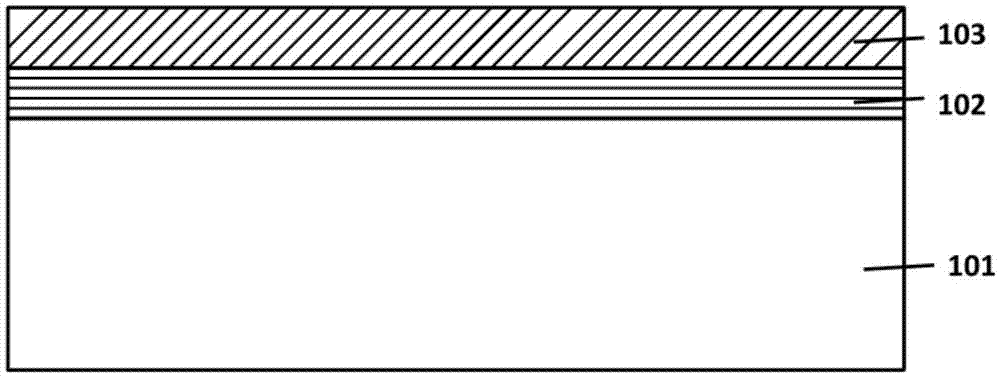

[0023] This embodiment provides a method for preparing a gate dielectric material on a silicon carbide substrate, the method is as follows:

[0024] (1) First pass through the N on the surface of silicon carbide 2 3nm-thick silicon oxide is grown by annealing in an O environment, and the predetermined temperature is 1200°C;

[0025] (2) Then adopt the method of atomic layer deposition on the substrate that step (1) completes to prepare the Al2O3 dielectric thin film 1 period, the precursor adopts trimethylaluminum and water, then adopts the precursor and adopts trimethylaluminum and ozone method to grow Al2O3 dielectric film for one cycle, and then use nitrogen plasma to purge the surface of the dielectric;

[0026] (3) Cycle 10 times according to step (2);

[0027] (4) Finally, the silicon carbide wafer with the gate dielectric grown on the N 2 Anneal for 1 minute under O environment, and the predetermined temperature is 900°C.

[0028] In the above-mentioned embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com