Ultrasonic Motor Optimal Frequency Tracking Control System and Control Method for Keeping Minimum Input Power

An ultrasonic motor, input power technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem that the ultrasonic motor cannot be guaranteed to work in an optimal working state. , to achieve the effect of stable characteristics, small input power, and improved stable characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

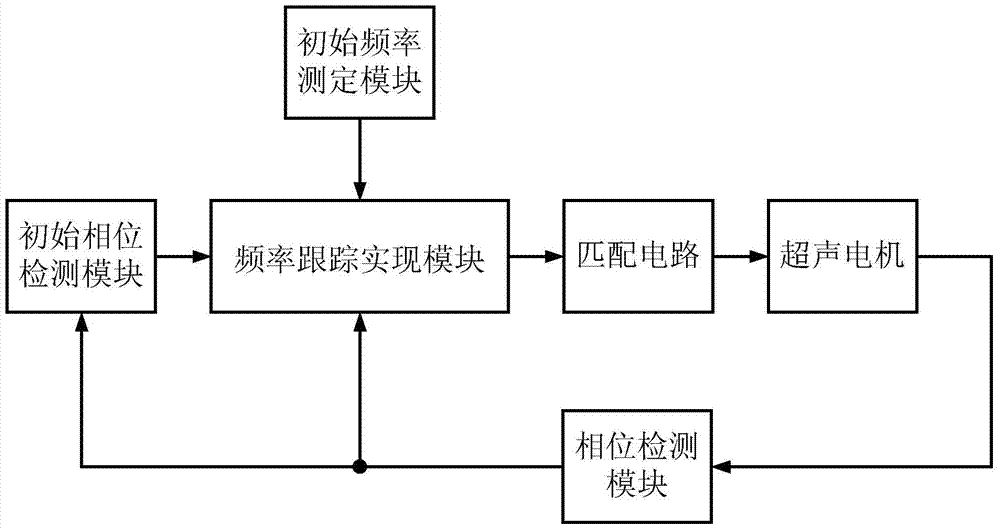

[0025] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the optimal frequency tracking control system of an ultrasonic motor that keeps the minimum input power described in this embodiment, the control system includes an initial frequency measurement module, an initial phase detection module, a phase detection module, a frequency tracking realization module and a matching circuit;

[0026] The initial frequency measurement module is used to determine the working frequency corresponding to the optimal working state of the ultrasonic motor, and use this working frequency as the initial frequency;

[0027] The initial phase detection module is used to determine the initial phase of the ultrasonic motor in the first sampling period when the ultrasonic motor works at the initial frequency;

[0028] The phase detection module is used to detect the phase difference between the input current and voltage of the ultrasonic motor in real time...

specific Embodiment approach 2

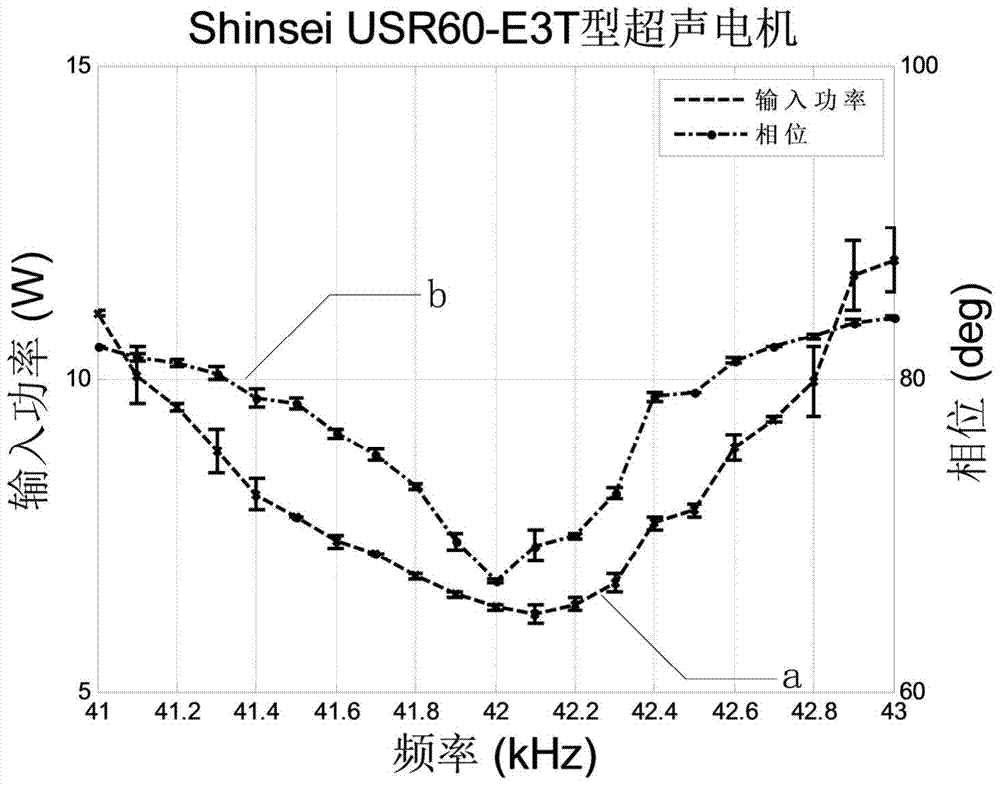

[0033] Specific implementation mode 2: This implementation mode further explains the implementation mode 1. The specific process of determining the initial frequency by the initial frequency measurement module is as follows:

[0034] Keep the ultrasonic motor at a constant speed, measure the power spectrum characteristics of the ultrasonic motor, and the operating frequency corresponding to the minimum input power point is the initial frequency.

specific Embodiment approach 3

[0035] Specific implementation mode three: this implementation mode further explains implementation mode one, and the specific process for the frequency tracking implementation module to generate the driving voltage signal of the ultrasonic motor is as follows:

[0036] Collect the phase sampling value of the current sampling period, make a difference between the phase sampling value and the initial phase value, convert the difference into the change in the frequency value of the driving signal, and make the difference between the variable frequency value and the working frequency obtained in the previous sampling period, and the obtained The difference value is used as the frequency value of the drive motor signal, through power amplification, the frequency value is generated into a two-phase quadrature drive voltage signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com