Crankshaft automatic indexing hydraulic clamp

A hydraulic fixture and automatic indexing technology, which is applied in clamping, clamping devices, manufacturing tools, etc., can solve the problems of large eccentricity error, low crankshaft machining efficiency, and poor crankshaft machining accuracy, so as to improve machining accuracy and improve Processing efficiency, clamping and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

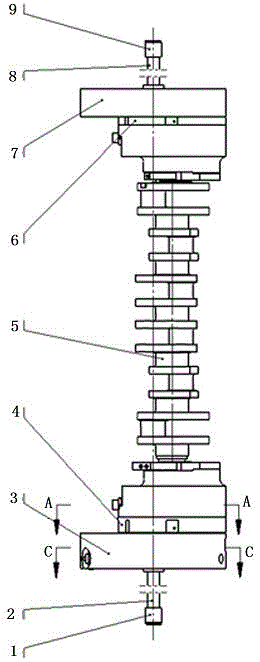

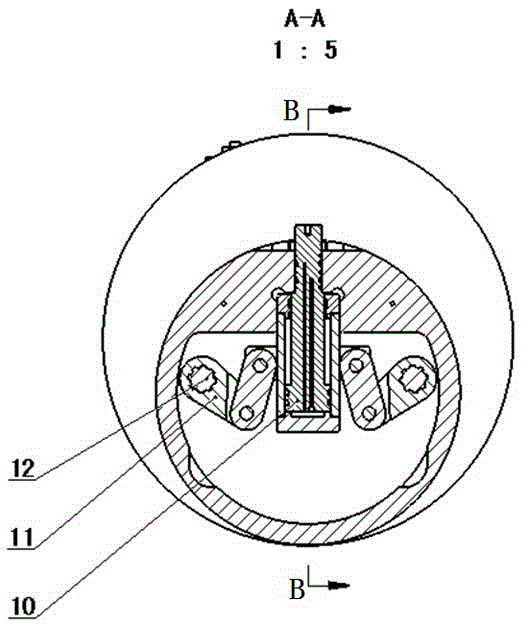

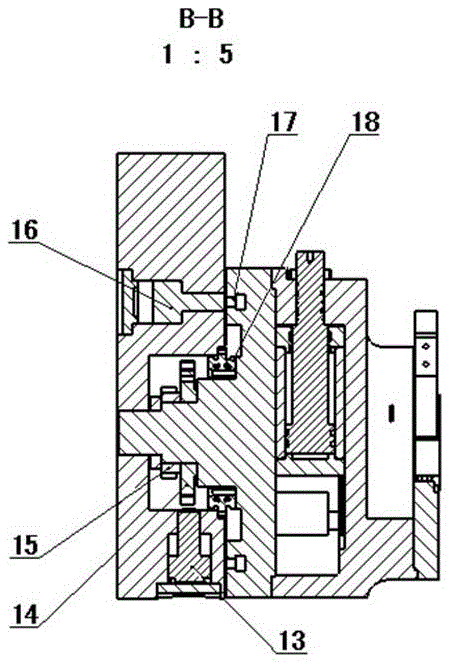

[0020] Combine below Figure 1-5 The present invention is described in detail to clarify the structural features and usage methods of the present invention.

[0021] A crankshaft automatic indexing hydraulic clamp, the crankshaft 5 is installed between the front and rear clamps, the cylinder 10 is clamped after radial positioning by the main shaft, and the clamping claw 19 is connected with the hinge arm 11 and the transmission shaft 12, and the clamping claw is driven 19 crankshafts are clamped, and the above parts are all installed on the front main shaft 4.

[0022] The front main shaft 4 is installed on the front clamp body 3 through the bearing 18, and can rotate on the front clamp body 3. The rear end of the front main shaft 4 is equipped with a precision indexing chainring 14 and a ratchet wheel 15, and the indexing oil cylinder 22 stirs the front main shaft 4 and the crankshaft 5 to rotate together through the swing arm 23. The stroke of the index cylinder 22 is adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com