Aerated aerobic and aerobic biofilm digestion reaction device and method

A technology of reaction device and aeration device, applied in chemical instruments and methods, aerobic and anaerobic process treatment, sustainable biological treatment, etc., can solve the problem of low oxygen conduction efficiency, difficult repair and maintenance, and aeration head failure and other problems, to achieve the effect of reducing volume and investment cost, easy disassembly and maintenance, easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

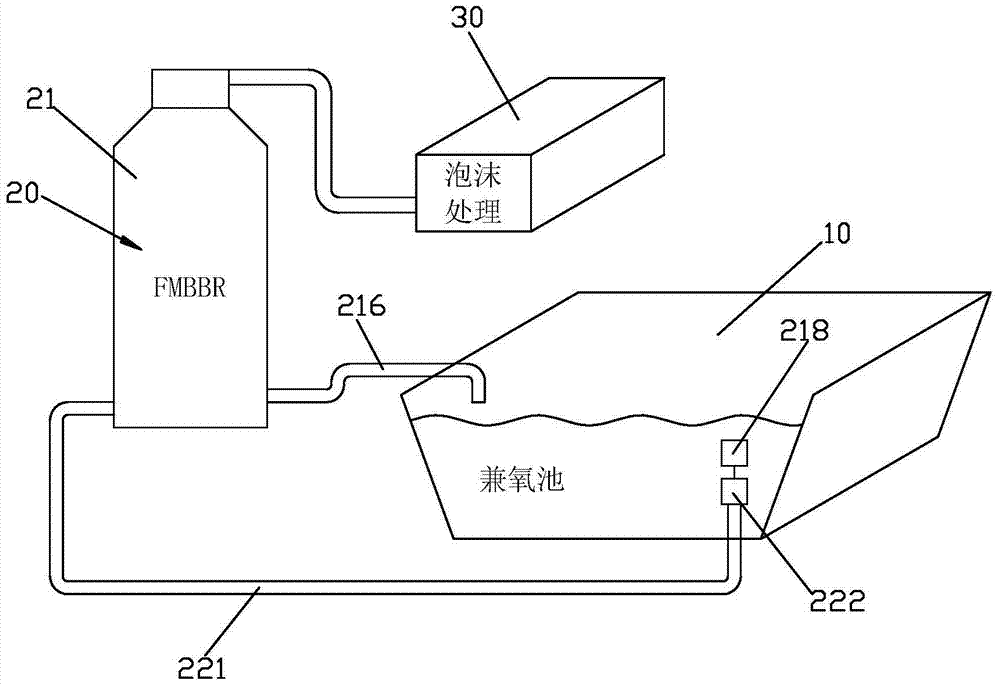

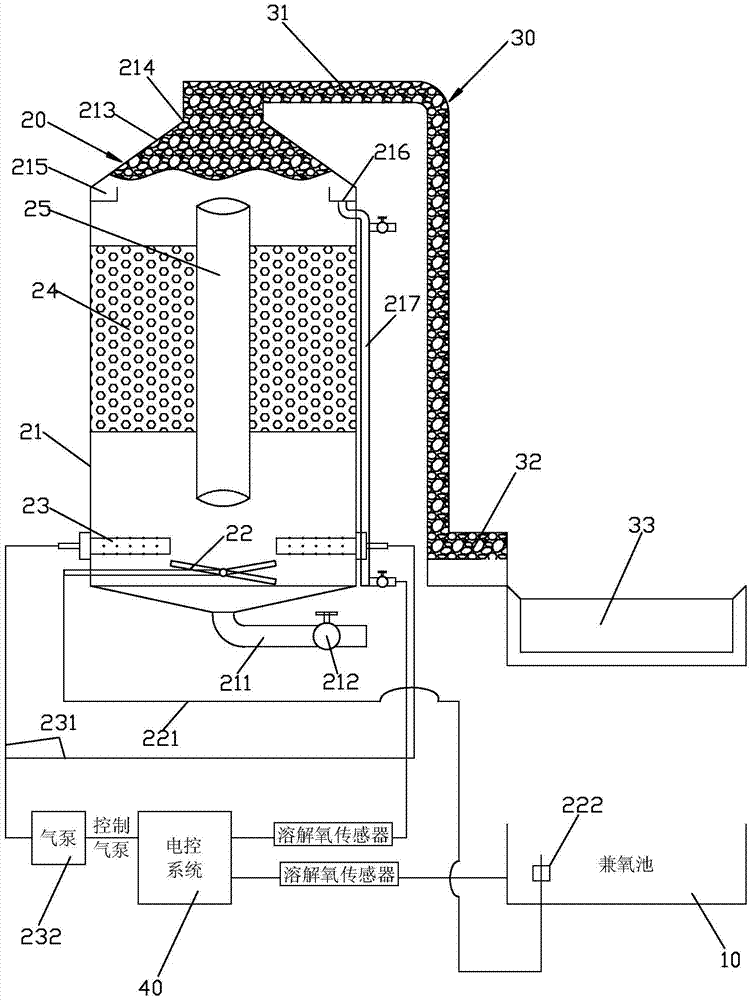

[0037] Please check figure 1 and figure 2 , an aerated aerobic and facultative biofilm first reaction device, including a facultative tank 10, a digestion reaction tower 20 and a foam treatment device 30.

[0038] The digestion reaction tower 20 includes a tower body 21 , and the tower body 21 is provided with a water outlet 216 . A mud discharge port is arranged at the bottom of the tower body 21, and the mud discharge port is connected with a mud discharge pipe 211, and an on-off valve 212 is arranged on the mud discharge pipe 211. The top of the tower body 21 is provided with a foam collection structure 213. The cross-sectional area of the foam collection structure 213 gradually becomes smaller, such as a conical structure with a small top and a large bottom. . The tower body 21 is equipped with a water distributor 22 for distributing sewage, an aeration device 23 for generating aeration bubbles, a biofilm carrier packing layer 24 that can make the aeration bubbles be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com