Automatic inspection method and device for aluminum electrolysis cell condition

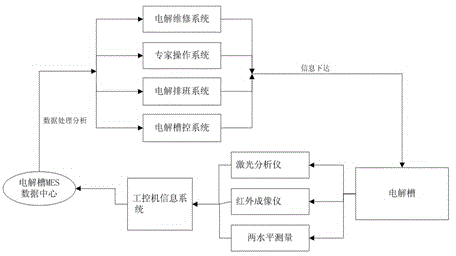

An aluminum electrolytic cell and automatic inspection technology, which is applied in the field of inspection robots and automatic inspection of aluminum electrolytic cells, can solve the problems of high cost of manpower and material resources, large amount of sample data, and time-consuming, etc., to achieve efficient use , Improve management efficiency and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

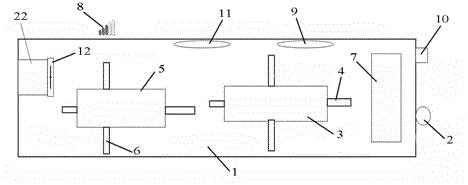

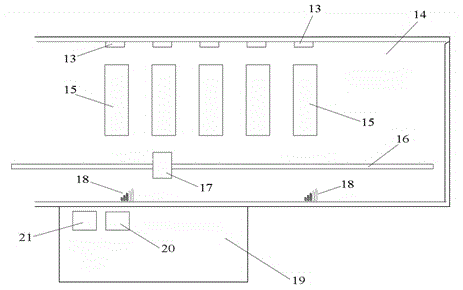

[0031] The present invention is implemented in this way, the inspection robot 17 includes a transport trolley 1 and a walking tracking and positioning device 2, and the transport trolley 1 is set according to the walking positioning device on the ground of the electrolysis plant 14, such as the navigation line 16 in the workshop, passing through the smart card scanner 9 , scan to the smart card information on the electrolyzer 15 for positioning. The positioning information enters the industrial computer 7, the transport trolley 1 stops, and the laser analyzer 3 used to detect the laboratory analysis data of the electrolyte and aluminum liquid in the electrolytic cell transmits the laboratory data detected on site to the industrial computer 7 and the electrolyte automatic temperature measurement infrared imager 5. After the inspection robot 17 is in place, the positioning robot arm of the robot, according to the predetermined test requirements, aligns the infrared test head with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com