Differential linear density blend fiber and preparation method for same

A technology of different deniers and manufacturing methods, which is applied in the field of mixed fibers of different deniers and the preparation of the blended fibers, can solve the problems of monofilament fineness and thickness limitation, insufficient softness of fabrics, etc., and achieve excellent hand feeling and dyeability, excellent dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] The test method that the present invention relates to is as follows:

[0024] (1) Fineness

[0025] Tested according to standard JISL1013:2010.

[0026] (2) The number of islands on the cross-section of a single fiber

[0027] Cut the fiber into thin slices along the long direction (that is, the fiber cross section), and observe the number of islands under an ordinary optical microscope.

[0028] (3) Cross-sectional area of a single island

[0029] Cut the sea-island composite fiber into thin slices along the cross-section of the fiber, and then use the SS550 type walk-through electron microscope (SEM) produced by Shimadzu to take photos of the obtained fiber cross-section at an appropriate magnification. Then use the image processing software (WINROOF) to calculate the island area of the photos, and the final result is represented by the average value of 10 sea-island composite fiber sections.

[0030] (4) Dyeing evaluation

[0031] The combined fiber is subje...

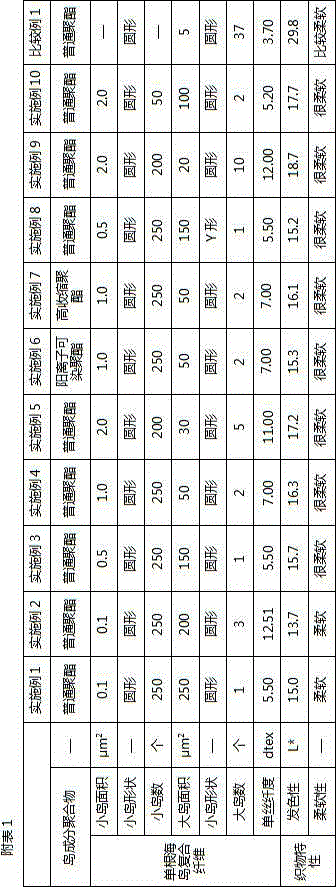

Embodiment 1

[0044] Alkali-reduced polyester is used as the sea component, common polyester is the island component, and the sea-island weight ratio is 30 / 70. It is obtained after melt spinning and false twisting on a spinning machine equipped with a distribution-type sea-island composite spinneret. Sea-island composite fiber with a fineness of 82.5detx and a single fiber count of 15. It was determined that the island area of the obtained fiber was 0.1 μm 2 , the number of small islands is 250, and the area of large islands is 250 μm 2 , the number of large islands is 1, the cross-sectional shapes of the small islands and large islands are circular, and the small islands and large islands are arranged randomly.

[0045] After the fiber is made into a fabric, it is used for weight reduction processing, and then dyed with a disperse dye. The L* of the fiber is tested to be 15.0, and the dyeability is excellent; the softness evaluation result is soft.

Embodiment 2

[0047] Alkali-reduced polyester is used as the sea component, common polyester is the island component, and the sea-island weight ratio is 30 / 70. It is obtained after melt spinning and false twisting on a spinning machine equipped with a distribution-type sea-island composite spinneret. A sea-island composite fiber with a fineness of 187.6detx and a single fiber number of 15. It was determined that the island area of the obtained fiber was 0.1 μm 2 , the number of small islands is 250, and the area of large islands is 200 μm 2 , the number of large islands is 3, and the cross-sectional shapes of the small island and the large island are circular. At the same time, the large island is arranged on the outside of the small island.

[0048] After the fiber is made into a fabric, it is used for weight reduction processing, and then dyed with a disperse dye. The L* of the fiber is tested to be 13.7, and the dyeability is excellent; the softness evaluation result is soft.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com