Anti-transparent and ultraviolet-resistant warp-knitting fabric and purpose of same

An anti-ultraviolet and fabric technology, applied in warp knitting, application, protective clothing, etc., can solve the problems of lack of water absorption and quick-drying performance, short wearing life, unsuitability, etc., and achieve excellent anti-permeability and anti-ultraviolet effects, ventilation Excellent performance, easy to exercise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

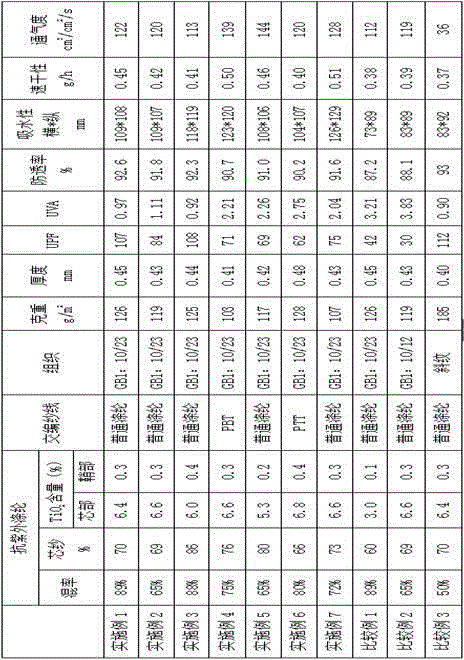

Embodiment 1

[0034] Using 75D-36f-anti-UV polyester DTY and 30D-36f-semi-dull ordinary polyester DTY for weaving on a 28G*218in tricot machine, the weaving structure is GB1: 10 / 23, GB2: 23 / 21 / 10 / 12 , And then carry out pre-treatment, dyeing and post-finishing processing (hydrophilic agent 10g / l, double cutting processing), the weight of the invention is 126g / m 2 , Warp knitted fabric with a thickness of 0.45mm. Among them, the blending rate of UV-resistant polyester DTY is 89%, the content of core yarn is 70%, the content of titanium dioxide in core yarn is 6.4%, and the content of titanium dioxide in sheath yarn is 0.3%; when weaving GB1: UV-resistant polyester DTY, fully worn ; GB2: Ordinary polyester DTY, one wear and one empty. See Table 1 for details.

Embodiment 2

[0036] Using 75D-36f-anti-ultraviolet polyester DTY and 30D-36f-semi-dull ordinary polyester DTY for weaving on a 28G*218in tricot machine, the weaving structure is GB1: 10 / 23, GB2: 10 / 12 / 23 / 21 , GB3: 23 / 21 / 10 / 12, and then carry out pre-treatment, dyeing and finishing processing (hydrophilic agent 10g / l, double cutting processing), the weight of the present invention is 119g / m 2 , Warp knitted fabric with a thickness of 0.43mm. Among them, the blending rate of UV-resistant polyester yarn is 65%, the core yarn content is 69%, the titanium dioxide content in the core yarn is 6.6%, and the titanium dioxide content in the sheath yarn is 0.3%; when weaving, GB1: UV-resistant polyester DTY, fully worn ; GB2: Ordinary polyester DTY, two wear and one empty; GB3: Ordinary polyester DTY, two wear and one empty. See Table 1 for details.

Embodiment 3

[0038] Using 75D-72f-anti-UV polyester DTY and 30D-36f-semi-dull ordinary polyester FDY for weaving on a 28G*218in tricot machine, the weaving structure is GB1: 10 / 23, GB2: 34 / 32 / 21 / 10 / 12 / 23, then pre-treatment, dyeing (hydrophilic agent 1.5% owf), finishing processing (double cutting processing), the weight of the invention is 125g / m 2 , Warp knitted fabric with a thickness of 0.44mm. Among them, the blending rate of UV-resistant polyester DTY is 88%, the content of core yarn is 86%, the content of titanium dioxide in core yarn is 6.0%, and the content of titanium dioxide in sheath yarn is 0.4%; when weaving, GB1: UV-resistant polyester DTY, fully worn ; GB2: Ordinary polyester FDY, one wear and one empty. See Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com