Highly anti-transparent sea-island composite fiber and fabric prepared from same

A composite fiber, anti-penetration technology, applied in the direction of chemical characteristics of fibers, conjugated synthetic polymer rayon, textiles and papermaking, etc. The effect of excellent impermeability and good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

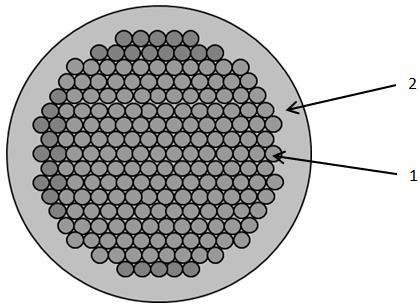

Image

Examples

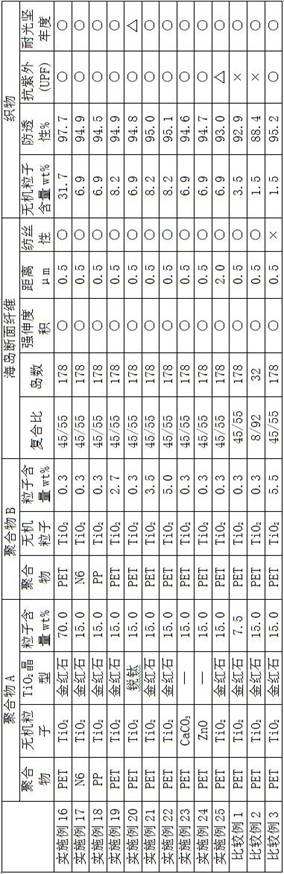

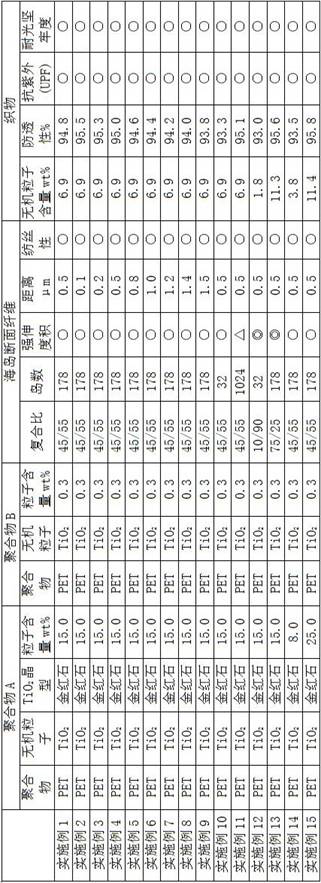

Embodiment 1

[0058] 45 parts by weight containing 15.0wt% rutile TiO 2 Particles of polyethylene terephthalate (PET) (island component) and 55 parts by weight containing 0.3wt% TiO 2 The semi-dull polyester (sea component) of the particles is pre-crystallized and dried to less than 50ppm, and put into the spinning A and B silos for spinning and false twisting to obtain long fibers with high anti-permeability. The cross-section of the fiber is a sea-island structure, the number of islands is 178, and the distance between the outermost island surface and the fiber surface is 0.5 μm. The obtained fiber is made into a tube knitted fabric, and the obtained tube knitted fabric has an anti-permeability of 94.8%, has an anti-ultraviolet property, and has a qualified light fastness.

Embodiment 2

[0060] 45 parts by weight containing 15.0wt% rutile TiO 2 Particles of polyethylene terephthalate (PET) (island component) and 55 parts by weight containing 0.3wt% TiO 2 The semi-dull polyester (sea component) of the particles is pre-crystallized and dried to less than 50ppm, and put into the spinning A and B silos for spinning and false twisting to obtain long fibers with high anti-permeability. The cross-section of the fiber is a sea-island structure, the number of islands is 178, and the distance between the outermost island surface and the fiber surface is 0.1 μm. The obtained fiber is made into a tube knitted fabric, and the obtained tube knitted fabric has an anti-permeability of 95.5%, has an anti-ultraviolet property, and has a qualified light fastness.

Embodiment 3

[0062] 45 parts by weight containing 15.0wt% rutile TiO 2 Particles of polyethylene terephthalate (PET) (island component) and 55 parts by weight containing 0.3wt% TiO 2 The semi-dull polyester (sea component) of the particles is pre-crystallized and dried to less than 50ppm, and put into the spinning A and B silos for spinning and false twisting to obtain long fibers with high anti-permeability. The cross-section of the fiber has a sea-island structure, and the number of islands is 178, and the shortest distance between the outermost island surface and the fiber surface is 0.2 μm. The obtained fiber is made into a tube knitted fabric, and the obtained tube knitted fabric has an anti-permeability of 95.3%, has an anti-ultraviolet property, and has a qualified light fastness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com